Imagine you’re a warehouse manager who oversees inventory and distribution to support production lines. You spend hours each week tracking inventory in two or three spreadsheets that you manually update. Because of gaps in the current process, you’ve had to delay builds and expedite shipping from your vendors to ensure you have the needed inventory. This affects production schedules and leads to near-stockouts. To provide real-time updates, you build inventory management into new and existing applications that pull data in real-time. This allows other areas of the plant to use the same data source to inform their operation and ensure inventory is adequately stocked.

Inventory management lets you keep track of what is in stock and what is used during builds, and define locations for materials, subassemblies, and final products. It also provides information to purchasing or procurement and finance, including restocking, kanban, and stock turns.

The table below provides examples of goals by tasks and how a digital inventory management system can help them get there:

| Task | Goal | How to Achieve |

|---|---|---|

| Planners | Improve production scheduling | Use sales forecast to predict and schedule inventory demand |

| Procurement | Cut costs for inventory acquisition | Place orders timely, saving efforts to tackle other initiatives listed |

| Inventory manager | Gain real-time visibility | Send alerts for low stock levels, discrepancies, or expiring items to ensure timely action |

| Kitting | Improve assembly and distribution | Create digital workflows for kitting based on production orders or customer specifications; implement digital kanban to ensure efficiency |

| Supply chain | Optimize logistics (just-in-time manufacturing) | Aggregate data to order at the right points (just-in-time manufacturing) (for example, via digital kanban) |

Impacts and Requirements

Traditional inventory management systems are manual and can be laborious to maintain. If your inventory spreadsheet does not automatically update, you quickly run into a lack of real time visibility. It is also more difficult to see granular levels of information.

Here are some benefits of digital inventory management:

-

Increased visibility

Gain real-time visibility into inventory levels, location, and status for current and historical inventory. This helps in better planning and decision-making, as managers can see exactly what is in stock, on order, or in transit. -

Accuracy and reduced errors

Reduce manual data entry errors and inaccuracies often associated with paper or spreadsheet-based systems. This improves overall inventory accuracy and reduces the chances of running out of stock or having too much. -

Scalability

Accommodate business growth with increased inventory volumes and complexities. This considers user access and supporting multi-location operations. -

Data analytics and reporting

Generate custom reports, analyze trends, and identify opportunities for process improvements or cost savings based on data-driven insights.

Any industry can benefit from digital inventory management. As a company scales, the increased production demands more inventory and a process to manage it. Companies that have a high mix have a greater need for this use case, because of the varying types of pieces to keep track of.

Inventory management has a medium to high complexity, depending on your existing inventory system. Minimum set up involves basic app building and an organized table structure. You may need to configure a connector to integrate with an external inventory management system, such as an ERP. You could also use plug-and-play barcode scanners or RFID technology to optimize performance.

How to Get Started

Before you begin building inventory management apps, it’s important to understand the problem that you’re trying to solve and prioritize what the solution needs to have. To do this, we recommend documenting the inventory flow process from creation to consumption.

Once you document the process and establish the problems that you’re trying to solve, you should create lists of needs and wants. This will help you to prioritize features by the pain you need to service.

| Problem | Feature to prioritize |

|---|---|

| Not knowing how much inventory exists or where it is | Table structure that holds inventory and relevant data |

| Infrequency of inventory replenishment | Analyses and/or dashboard to stay informed |

| Inaccurate data between the system and spreadsheet | Accurate and frequent communication through apps, or an Integration using connectors |

Store inventory data

There are two ways to store inventory data for use in Tulip:

Tables

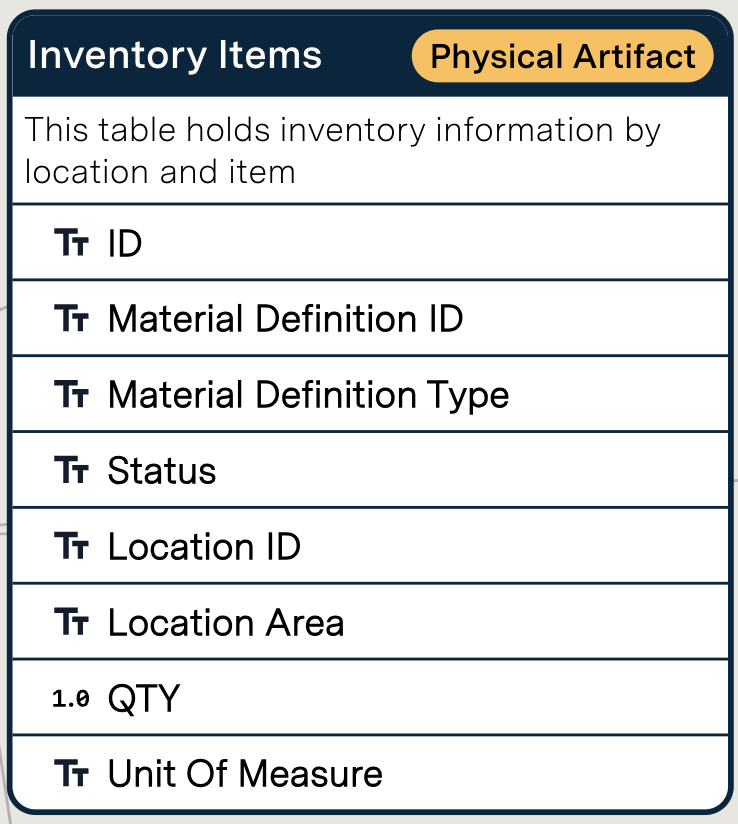

Store data in an Inventory Items table and create Fields that specify important information for each material.

Here’s a breakdown of each field in this table example:

| Label | Field Type | Description |

|---|---|---|

| ID | Text | * Required: unique identifier |

| Material Definition ID | Text | Unique identifier for the material |

| Material Definition Type | Text | Type of material of the inventory item |

| Status | Text | The current state of the inventory item |

| Location ID | Text | Current physical location of the inventory (e.g. station ID, location ID, or any arbitrary indication of location such as cell or unit) |

| Location Area | Text | Further subdivision of locations by area, which allows for grouping or filtering by area or zone |

| Quantity | Number | The quantity of the inventory record |

| Unit of Measure | Text | the unit of measure related to the quantity |

You may find it useful to build out a table structure that also stores data in Kanban Cards and Kanban Status History tables.

A table structure, which is often part of a common data model, is crucial for your apps to interact with each other. For example, a status update in a table is how an operator using an app at one Station can signal to an operator using an app at another station.

With inventory management, notifications of low inventory levels can circulate to managers, assembly, planners, and anyone else who needs real-time access to information.

ERP integration

Push data from an ERP or other external system that feeds into your Tulip apps. An ERP integration is complex and may require IT to help configure. When done correctly, it uses a source of truth to inform process data in Tulip. To set up an ERP integration in Tulip, you’ll need to create and configure a connector using the system’s API documentation.

Build apps

With inventory management, you are building a repository of information for items such as location, status, quantity, etc. It must be kept up-to-date with connections to other apps and adjacent systems.

A simple inventory management application we recommend starting with is a warehouse management application, shown below:

This app uses a table record widget to display Records of materials and associated fields, such as material ID, quantity, location ID, status, etc. The data comes from an Inventory Items table. A selected material displays a larger view on the right-side of the step using a table record widget. There are also buttons to edit data in the material record.

Additional functionality you might include are:

- Send alerts when quantity falls below a certain threshold

- Material requests that signal orders

- A dashboard of analyses to see inventory trends

As we covered earlier, the features you prioritize in your inventory management applications should solve a pain point. You can build more features into the solution as needed.

Extended methods

You may want to eventually build out a dedicated solution of apps that address inventory management. You can see an example of apps that work together in the diagram below, which uses Tulip’s composable Inventory Management app suite:

This solution incorporates elements of material management, including material disposition, material inspection, and material replenishment.

You can also integrate with other processes such as quality inspection, which can ensure kits meet specifications before distribution, or work instructions, which can create a seamless experience from start to finish.

Tulip Resources

Whether you want to learn more about Tulip features to build out inventory management or you want to use Tulip’s ready-made templates, we have the tools to help you get started.

.gif)

.gif)