The first step to driving business value from your machines is understanding their state. Collect machine state, track the key components of OEE, and drive business value with the Machine Monitoring Terminal Application.

Machine kit configuration

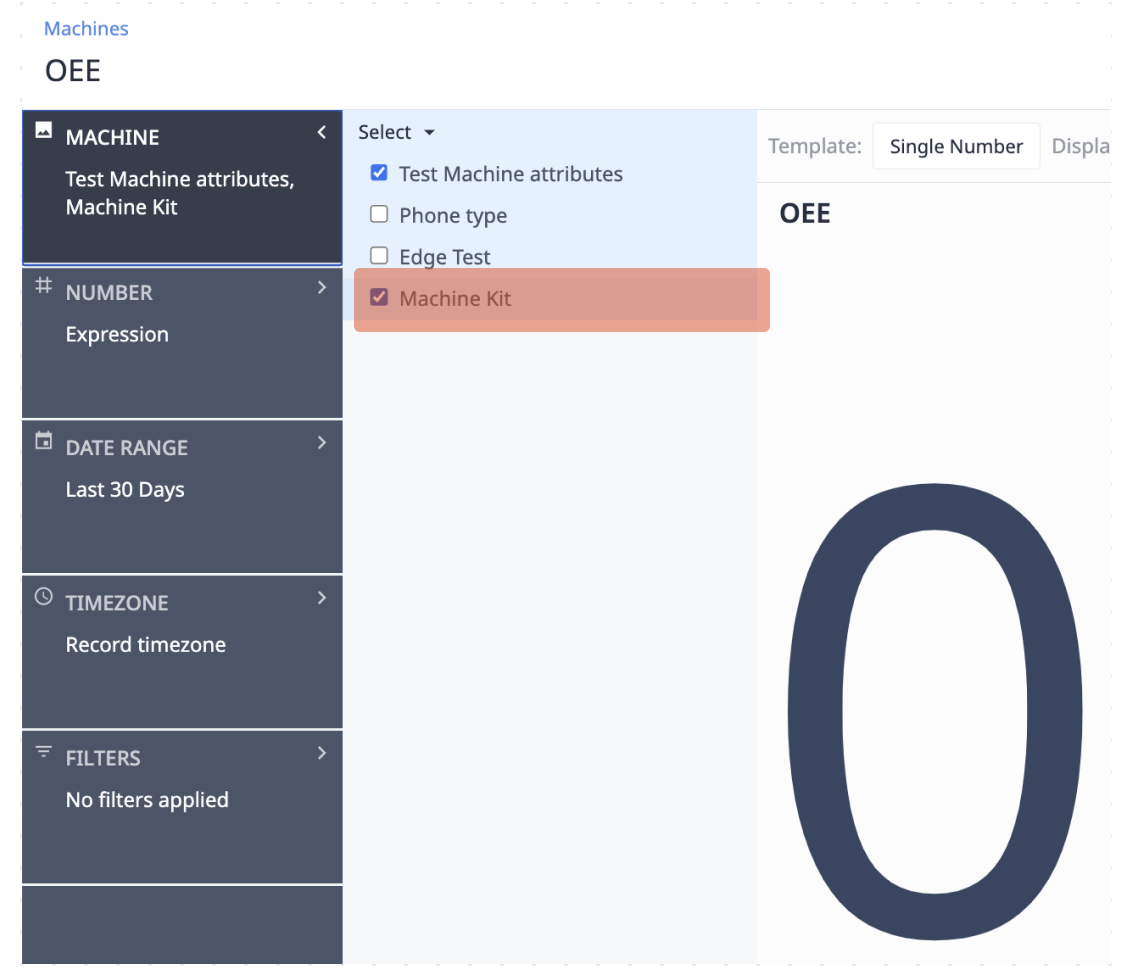

Before you can use this application with the Machine Kit offering, you have to configure the analytics first.

Open every analysis for editing, and on the Machine panel make sure that the Machine Kit type is selected as well.

Setup

Setup for this application is minimal. This application allows users to select any Machine that has been configured in your Instance.

Machine Type

Along with this application comes an example Machine Type. The Machine Kit type is a barebones starting point for leveraging the Tulip Machine Monitoring offering.

This machine has a Machine Current attribute that can be mapped to various different data sources. When this attribute goes above 10, the machine will be set to a running state, when it goes below 10, the machine will be set to Stopped. These thresholds can be adjusted in the Machine Type Triggers.

How it works

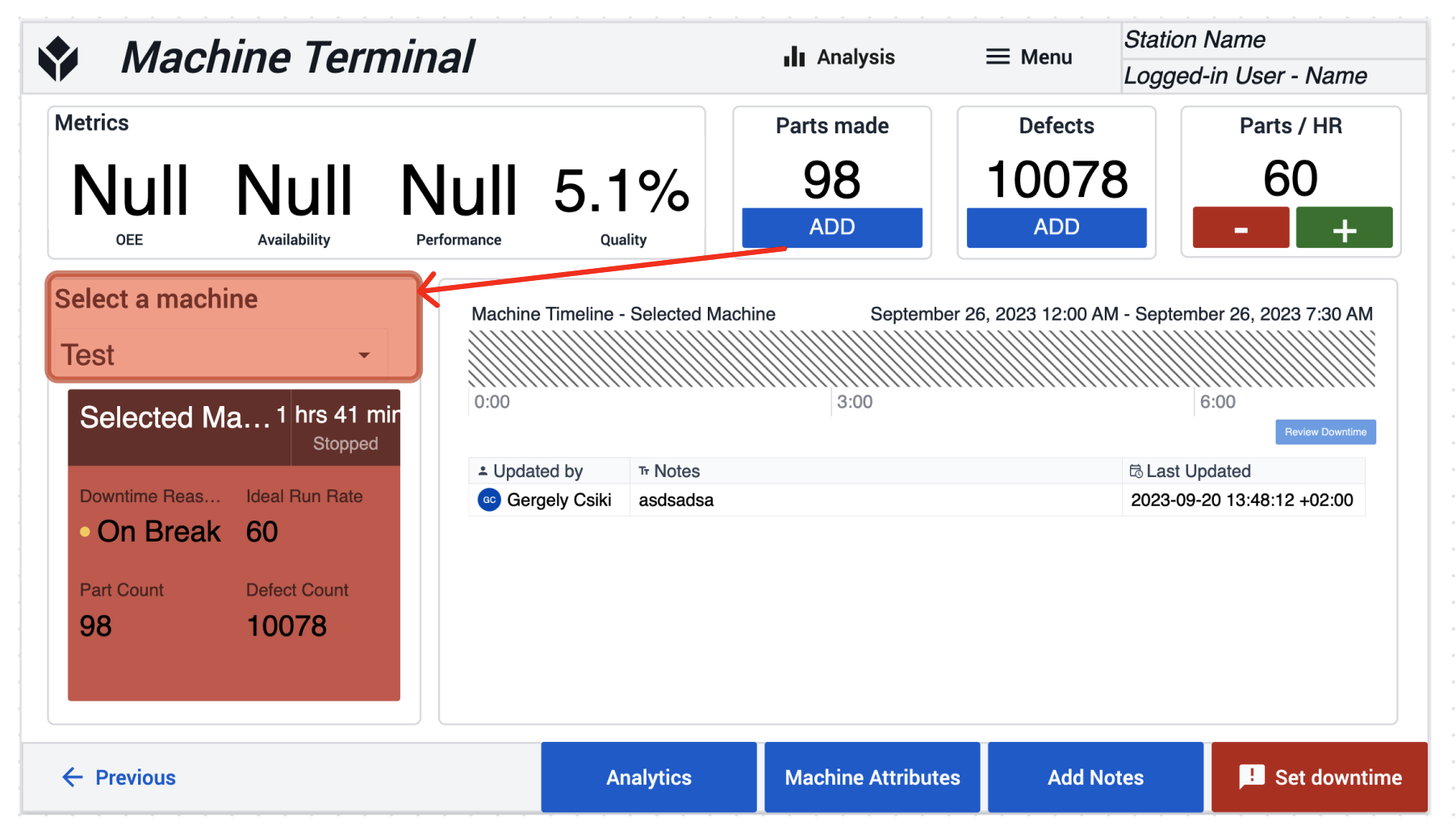

When a machine is selected, the machine terminal will automatically update with the data for the selected machine. You can leverage the machine type that comes with this application, or leverage your own.

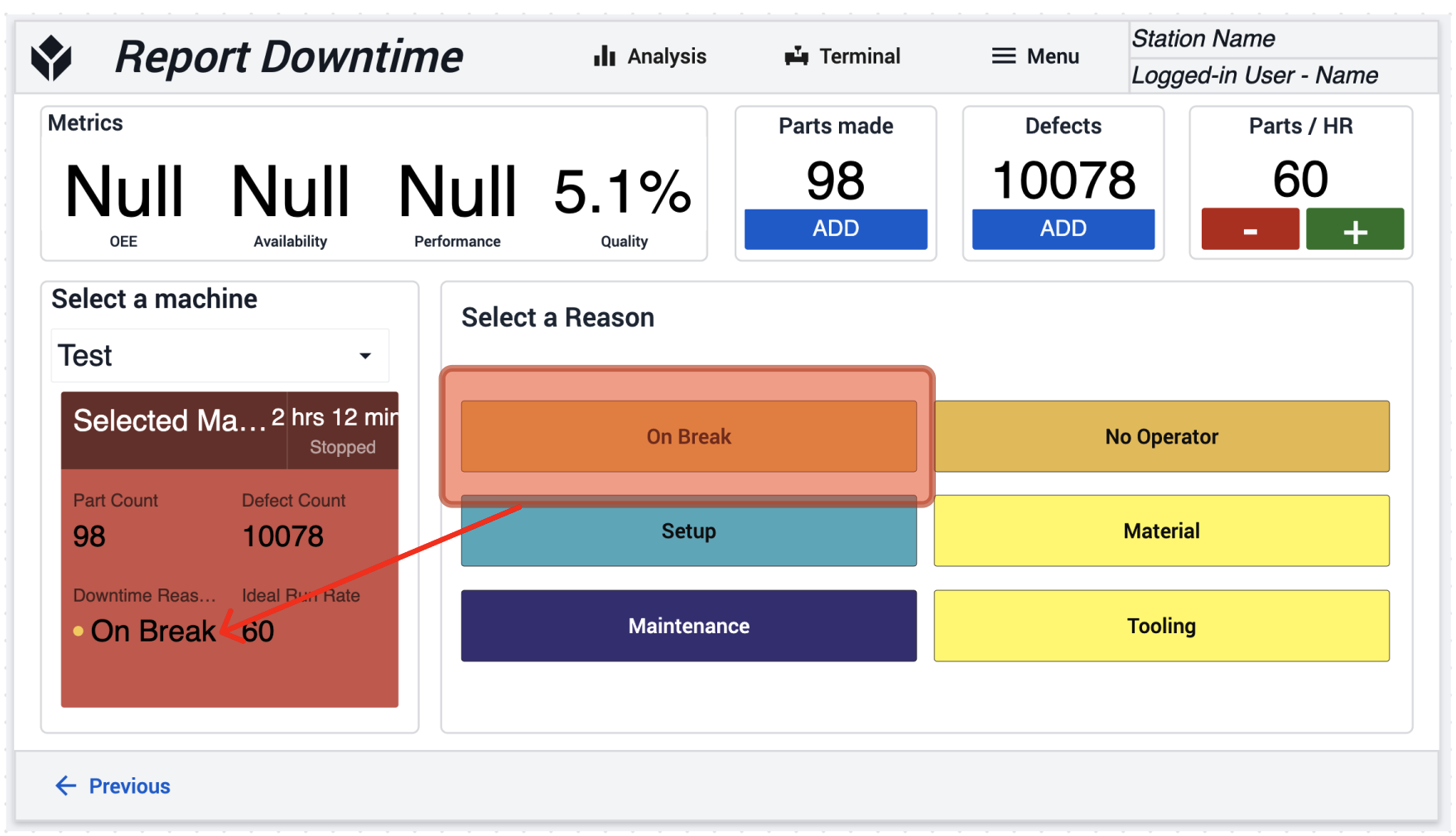

Downtime Tracking

When your machine enters a downtime state, a downtime reason can be assigned to that state to drive further visibility into root cause. Clicking on the Change Downtime Reason to select some example downtime reasons. Picking any downtime reason will assign a reason to the current downtime state.

OEE Tracking

Overall Equipment Effiency is built on 3 component parts:

- Quality

- Performance

- Availability

The definition of each of these components is heavily contested, but this app has these components implements by their widely accepted definitions:

Quality

Quality is the ratio of good parts reletive to the total number of parts. In short, this is the percent of good parts.

For example:

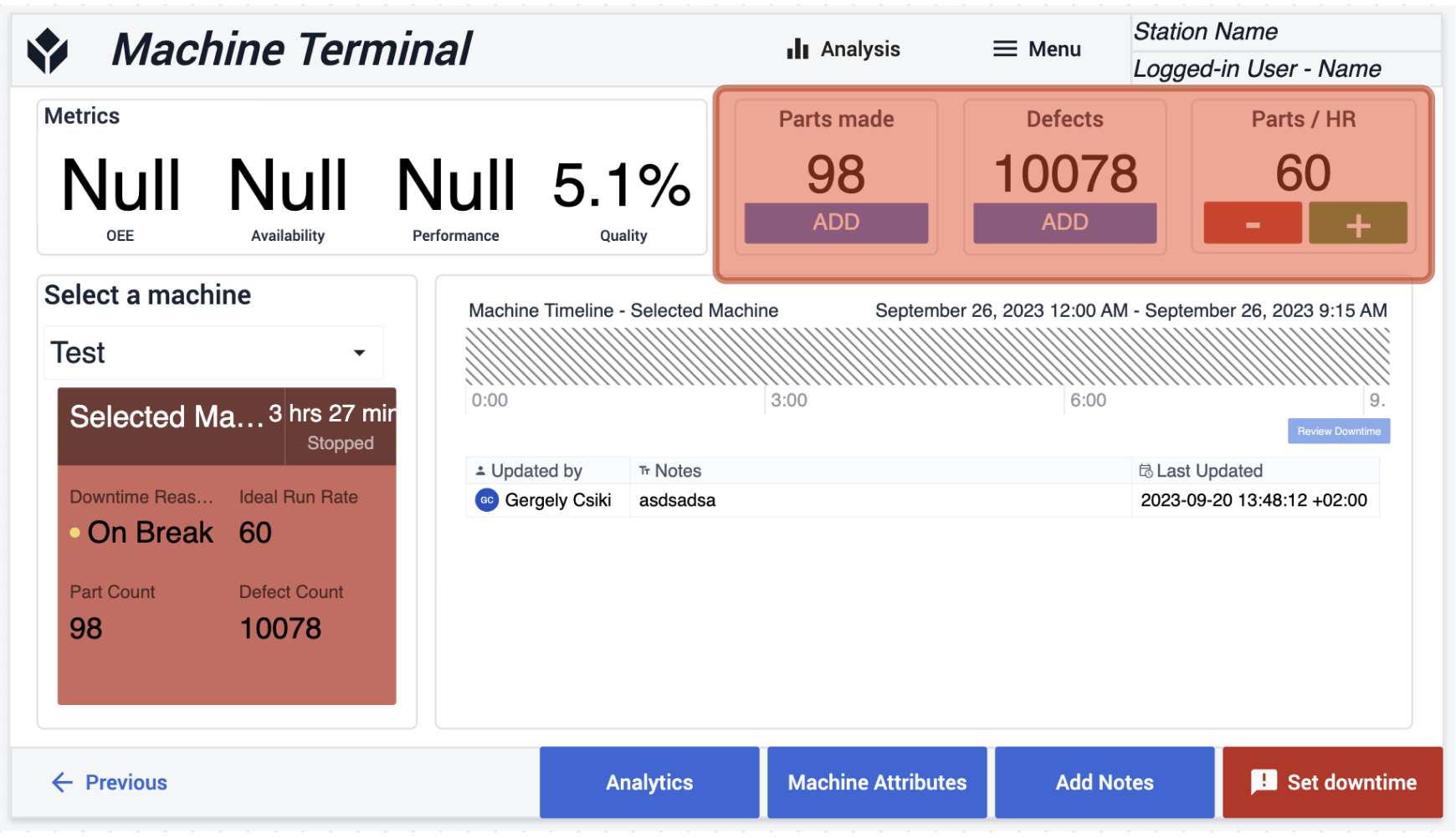

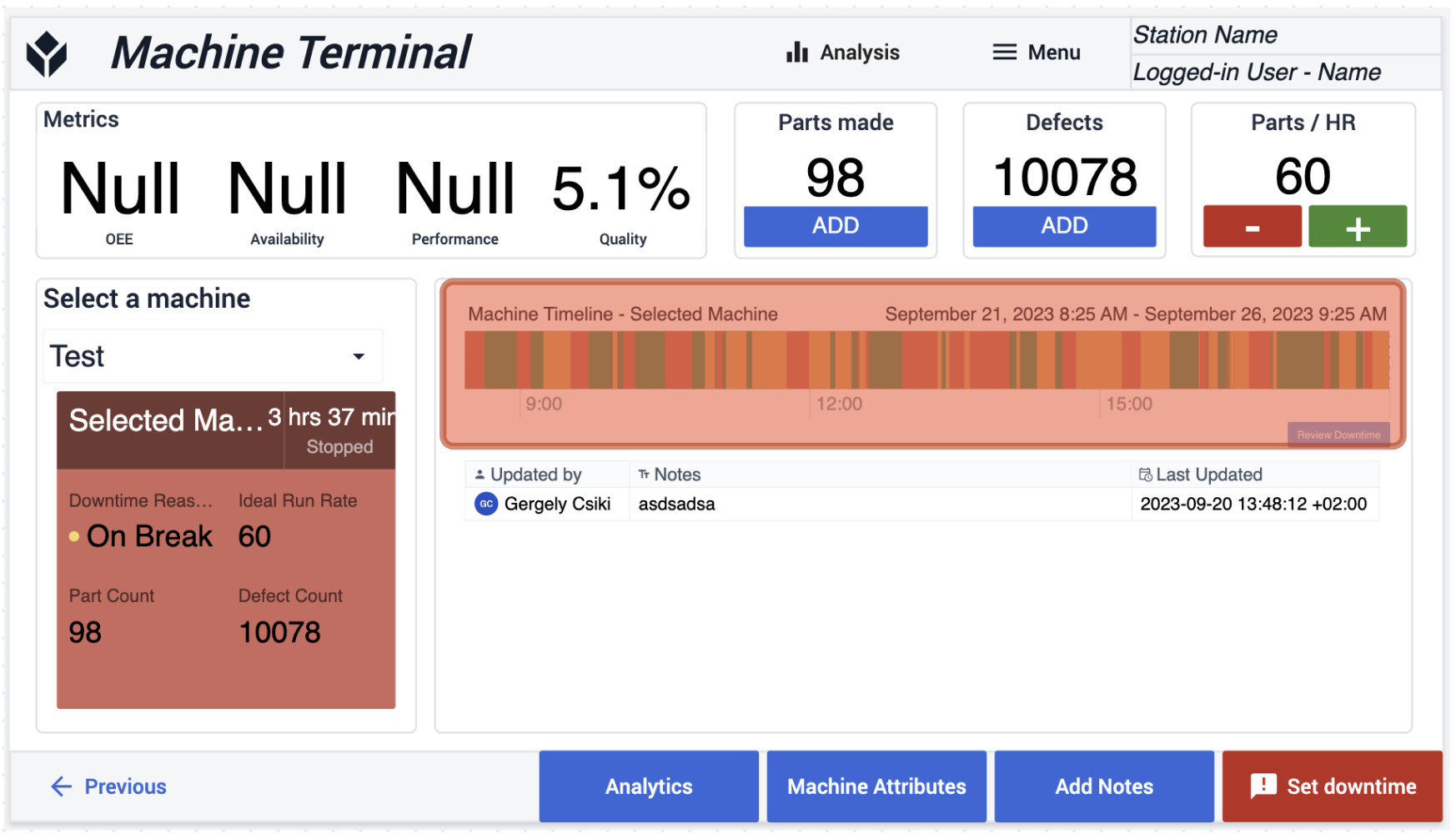

Within the Machine Terminal app, we track total parts and defective parts with the Add buttons under the Parts made and Defects part. We can also set an ideal Parts / HR value by the + and - buttons

Performance

Performance is the component to identify opportunity to run closer to the ideal run rate.

ex.

Our CNC machine when running ideally can produce 45 parts an hour, but in the last hour, we have only produced 32 parts.

In the Machine Terminal Application we track units produced with the Add buttons mentioned above and the ideal run rate (per hour) is set with the Parts / HR + and - buttons.

Availability

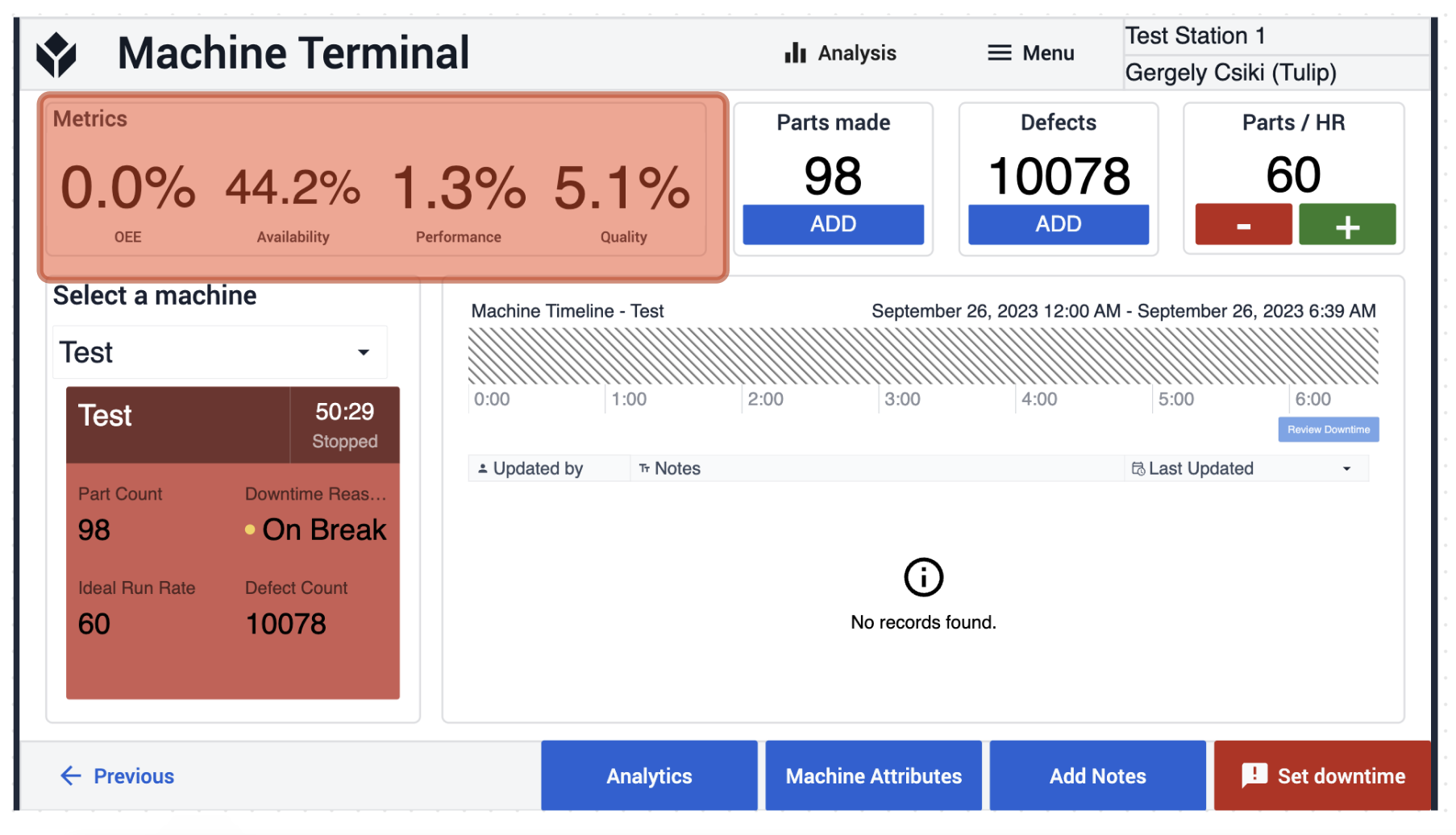

Availability is the component that tracks the uptime of your asset reletive to the available time. Within the Machine Terminal Application, we assume 24-hr operations, but this may differ for your facility.

Availability is automatically tracked by the Tulip Machine Monitoring offering. The "Running" state is tracked as uptime, and the "Stopped" state is tracked as downtime.

You can also see the the 3 OEE parameters individually and together as well on the top part of the application.

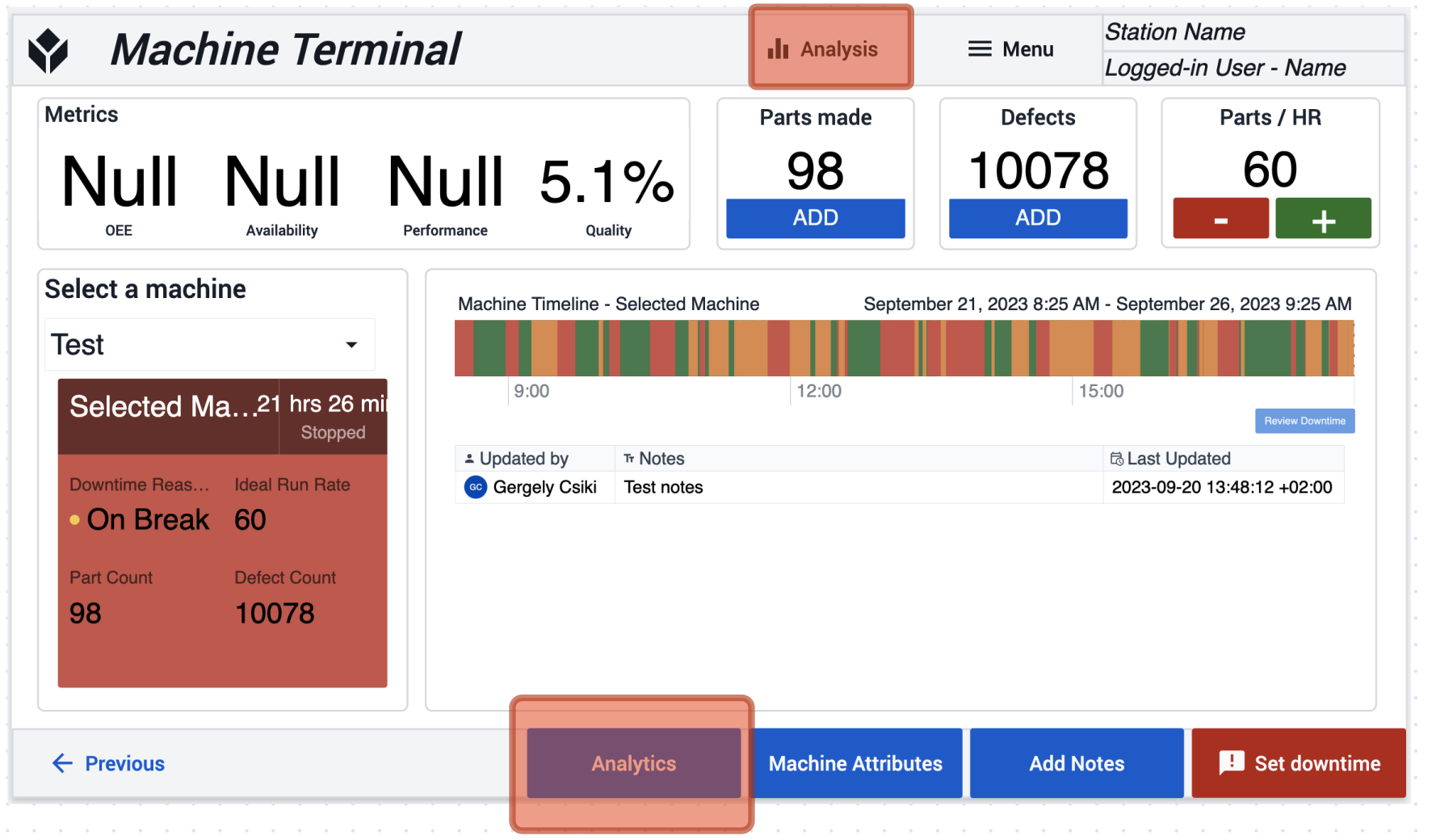

Analytics

Select the Analytics icon in the app ribbon or the button in the footer to see detailed historic breakdowns of each downtime reasons, along with hour-by-hour OEE logging.

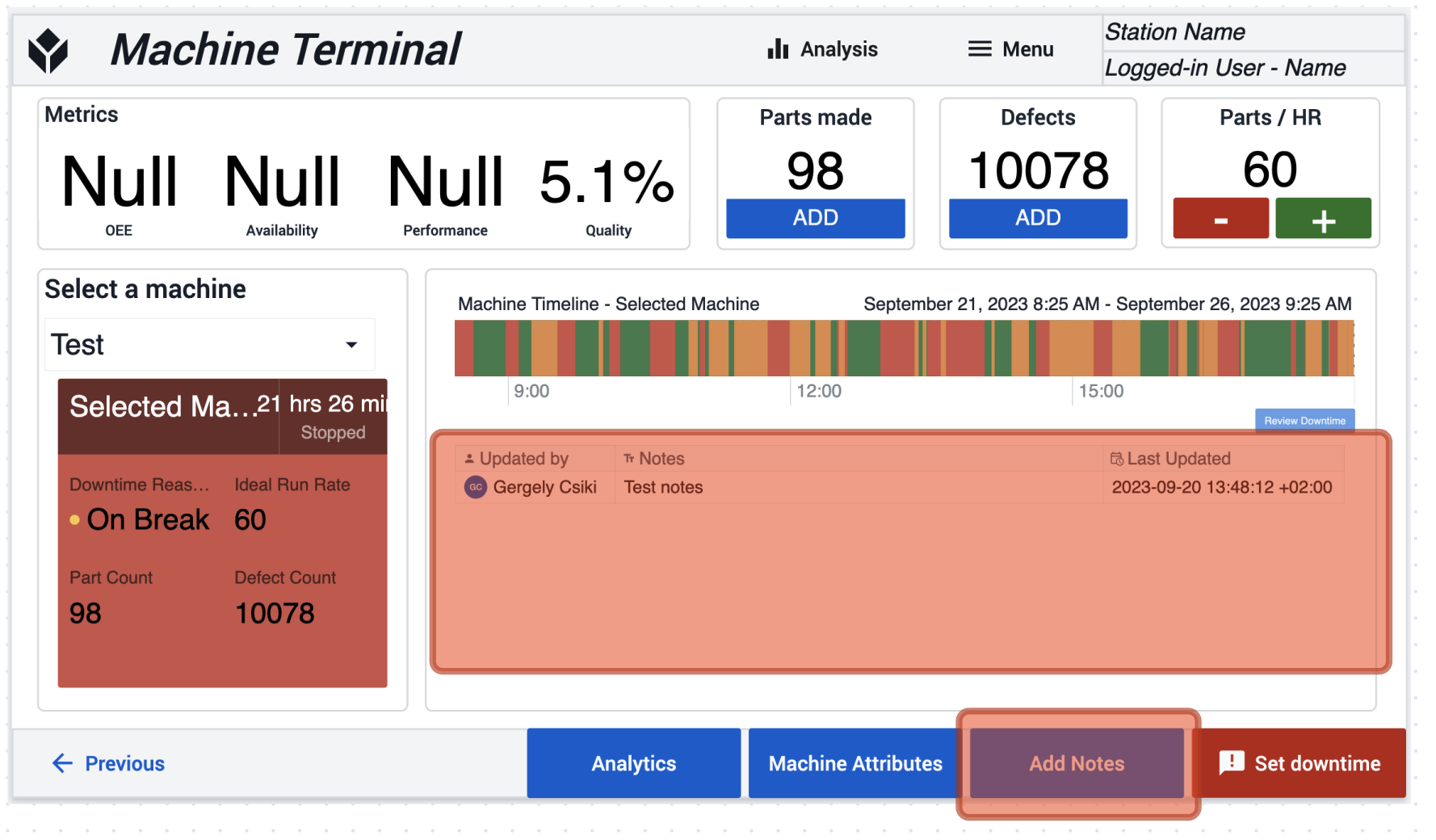

Notes

In the highlighted section you can see the added notes, which is useful for communicating important information during shift changes for example. If you want to add notes just click on the Add Notes button, which brings you to a page where you can do that.

Further Reading

This application is just a starting point for machine monitoring. Check out some of the other documents to go deeper!

- Machine Monitoring

- Managing Machine States and Part Counts with Edge IO and Node-RED

- Using Machine Data in the Analytics Editor