This article is a guide for app configuration that includes a functional breakdown of steps and ideas for connecting to other apps.

The Material Handling app is a part of Tulip’s composable MES Inventory app suite. You can use it individually or in combination with other applications.

The main function of this app is to process and deliver material requests created by other shop floor stations. Simple material movements can also be handled by this app between stations.

This application can streamline material replenishment and movements by reducing manual data entry and administrative overhead, allowing staff to focus on more value-added tasks.

Usage and Value Creation

Enable request selection and dynamic management of material movement by status—open, requested, or ready to deliver. With these digital solutions to handle material requests, users can optimize material flow and therefore reduce inventory surplus stocks as much as possible.

Tulip Tables in the app

All the applications in the Composable MES app suite use common tables.

The main Tulip tables used in this application is the Material Request and the Kanban Cards. Kanban cards is used to identify all the material storage containers in the shopfloor with all of its necessary informations, while Material request is used to handle all the replenishment and movement requests between these containers.

(Operational Artifact) Material Requests

- ID: Unique identifier for request

- Item: Identifies the part number of the requested material

- Requesting Location: Location where the request was made

- Supplier: Location where the requested material is stored

- Kanban ID: Identifies the Kanban container for the request

- Quantity: Amount of material requested

- Status: Current status of the material request

- Status Color: Current status visionalised by colours

- Requestor: Requesting operator personnel

- Assignee: Assigned operator for movement and replenishment

- Requested: Date/time of request was made

- Started: Date/time of start processing request

- Completed: Date/time of completed request

- Bin: Bin Requesting Location where material replenishment should be delivered.

- Compiled by: User who provided the material requested to fulfil the replenishment request.

- Ready for pick time: Ideal cycle time for picking up the filled container

- Delivered by: User who delivered the material to the Requesting Location.

(Operational Artifact) Kanban Cards

- ID: The unique identification of a kancan card

- Part Number:Item/Part/Material to be replenished.

- Status:Status of the kanban card

- Consuming location: Location that will consume the material replenishment request.

- Supplier: Location that will fulfill the kanban replenishment request.

- QTY: Quantity of Material of the kanban

- Part Description: Description of the Item/Part/Material to be replenished.

- Status Color: Color status of the kanban card

- Image: Image of the material to be replenished

- Active: Is the kanban card active?

- Lead Time: The time expected from empty to replenish, can be used to set a due date

Configuration and customization

In-app help

As with all applications in the Composable MES app suite, the Material Handling app includes in-app help as well. These are short descriptions of the Required setup steps and App builder tips to support further customization. After downloading the app make sure to read these instructions and then delete them before running the application.

Tables that provide data input

To be able to use the application some tables need to be populated. In this specific case you need Kanban cards and their respective real life containers. There are several ways to accomplish this: you can populate the Kanban Cards table manually, or simply have all these information imported from a 3rd party ERP software through Tulip Connectors.

Other configuration needs

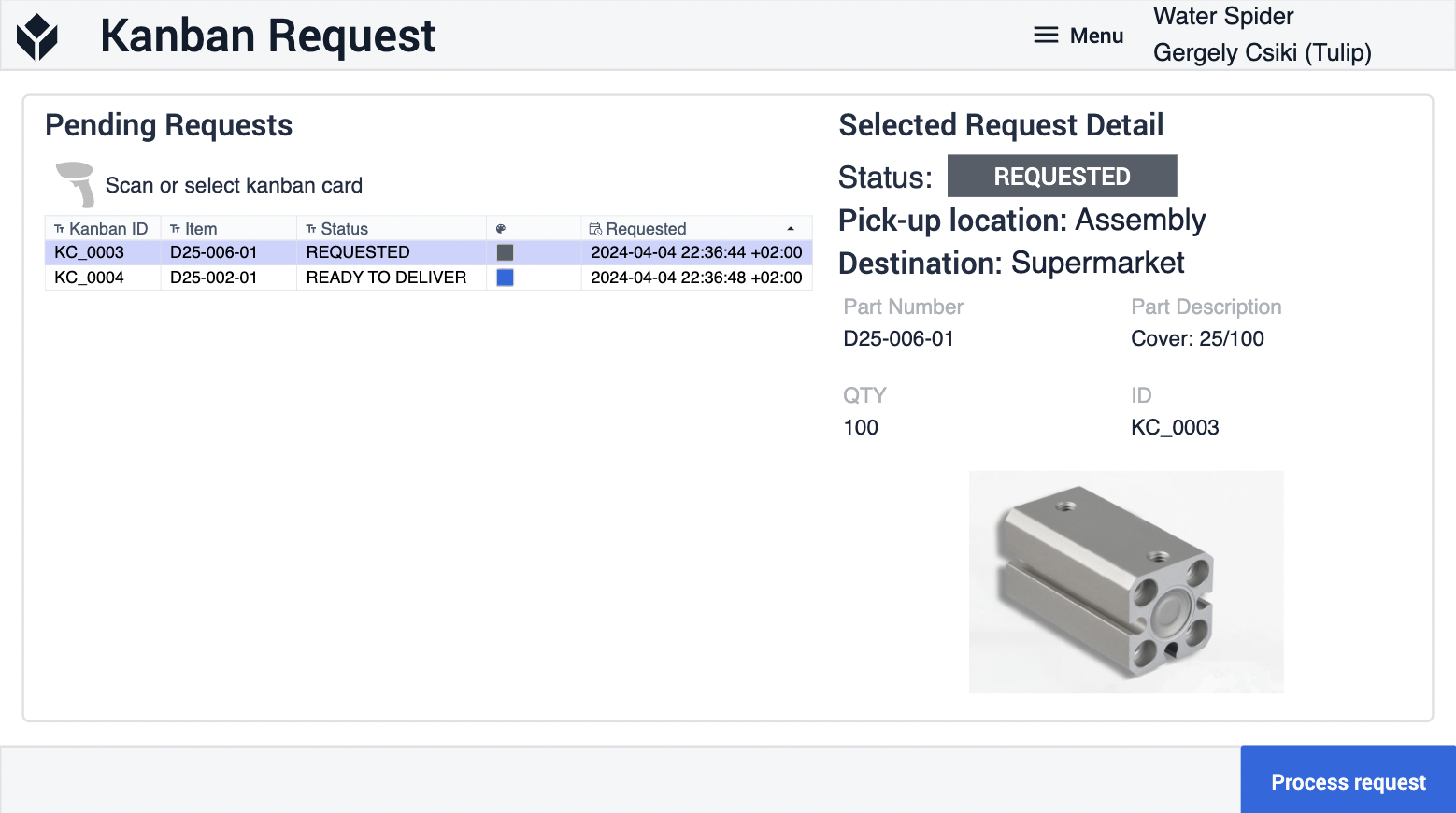

- On the Kanban Request step make sure to add filter for status of the material request. This allows the operator to only focus on still pending requests, filtering out all the already completed ones.

- Also there is an option to scan the barcode of the container, for that your actual barcode scanner need to be configured to the already existing machine trigger.

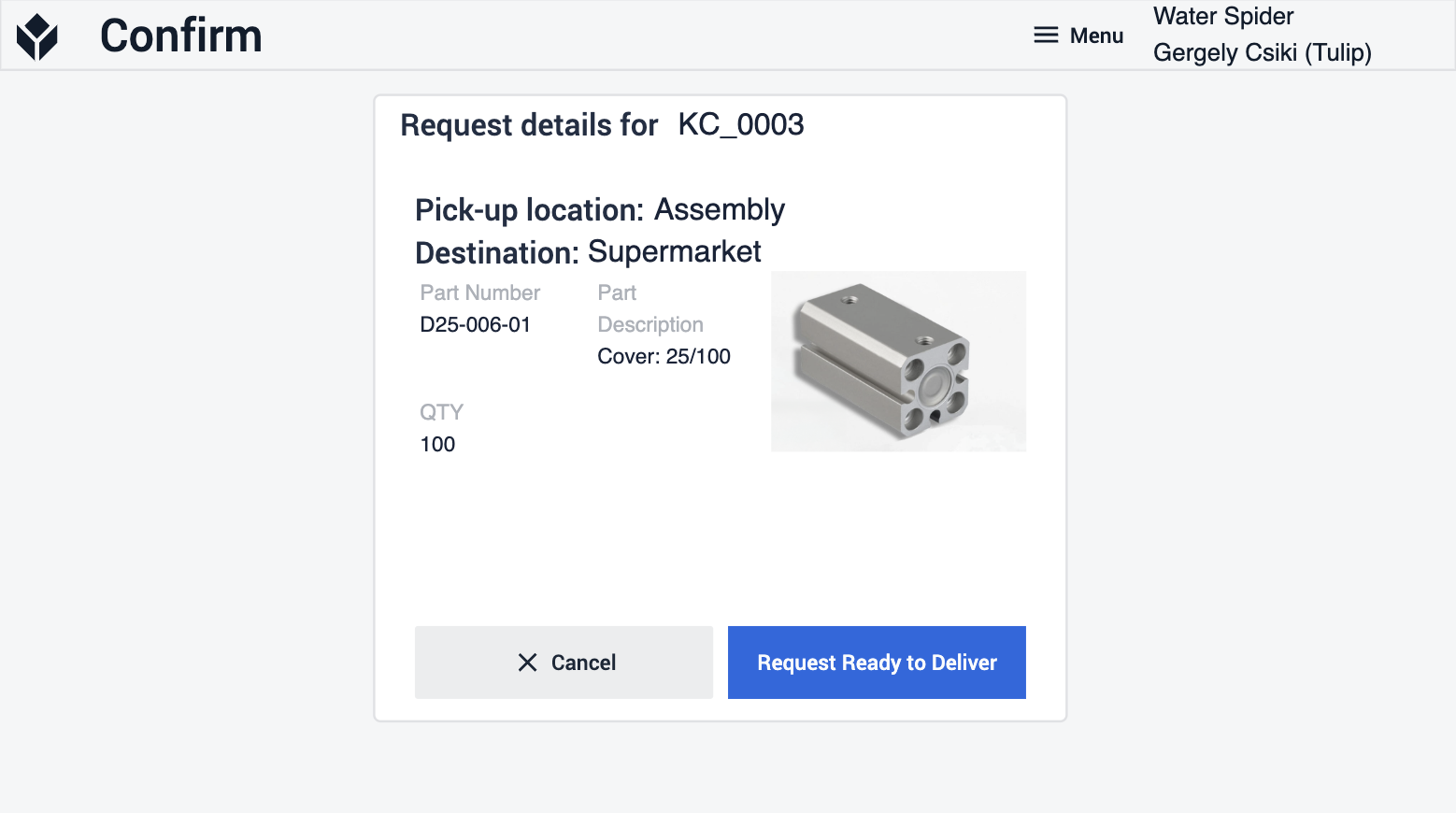

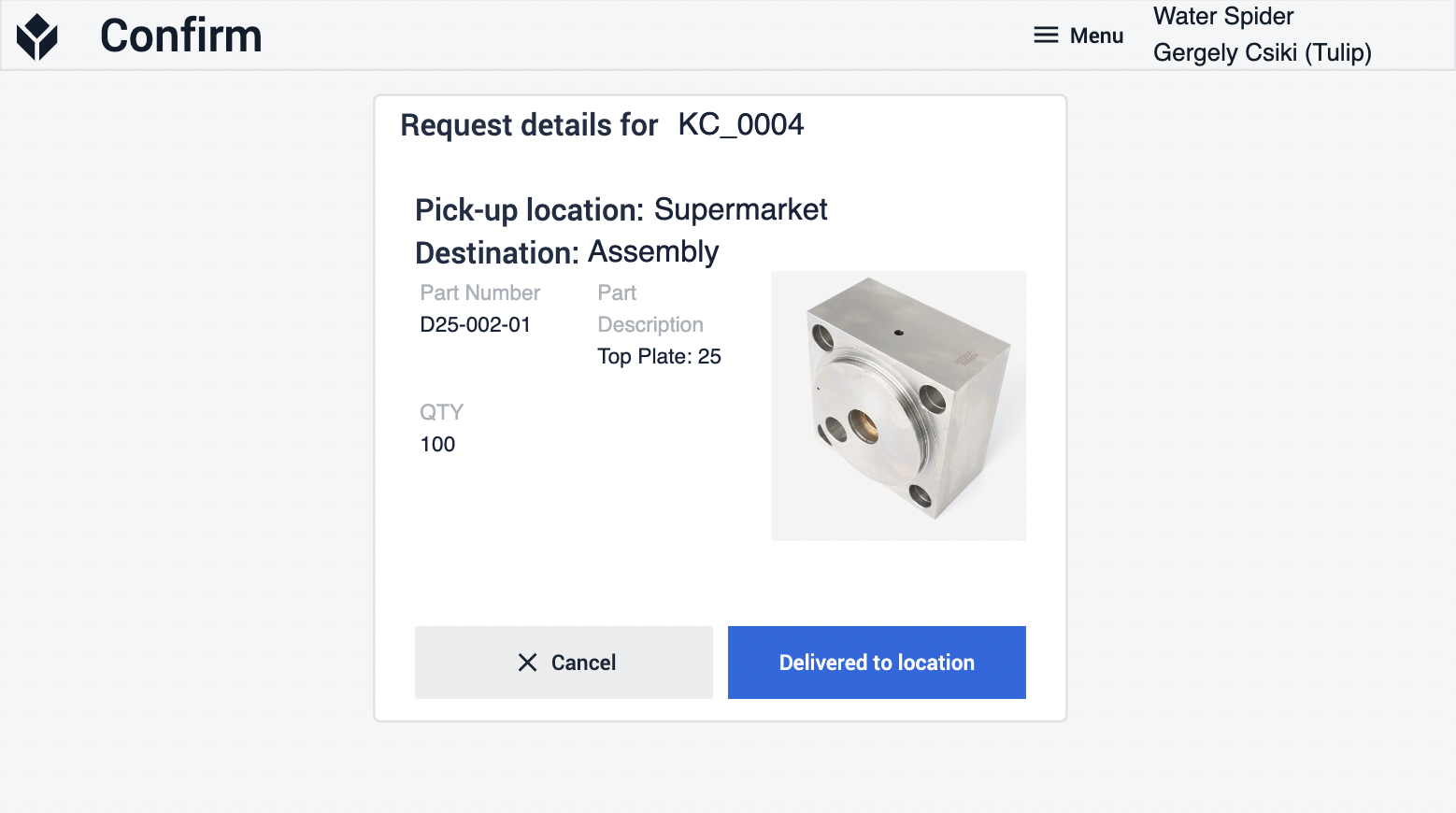

- On the Confirm step make sure to configure the button trigger with the correct Material request statuses according to your processes.

Customization options

- On both steps, add or remove fields in the selected Material Request Record Placeholder widget according to your company standards..

App Structure

On the Kanban Request step, the user has to select a material request to execute.

Upon clicking Process request, the user is directed to the Confirm step, where they can review the request details. The text displayed on the button, as well as the trigger logic, both depend on the current status of the request

Here, you can see two options when the request status is either Requested or Ready to deliver:

Extended App Connections

Examples for connecting apps to work with each other

Material Request

The material requests created using the Material Request app can be carried out and completed through the Material Handling application, which is also a part of the Inventory App Suite.

Inventory Dashboard

The Inventory Dashboard app, also part of the Inventory App Suite, can display and analyze all the pending and completed material requests along with their relevant details in real time.

Replenishment

The material requests created by the Replenishment app can be executed and fulfilled using the Material Handling application, both of which are part of the Inventory App Suite. Usually, this station serves as the main replenishment location for these requests originating from the shop floor.