Read and write orders from your Katana ERP system

This connector is a good starting point that implements a core set of the service's most common functions. You should expect to extend it by adding functions for the specific endpoints your workflow requires. Additionally, some configuration may be required in Katana ERP to establish a connection with Tulip. Please review our connector framework to learn more about how to build and modify connectors in Tulip.

Introduction

Katana is a cloud-based manufacturing ERP (enterprise resource planning) software for small and midsize businesses looking for an affordable as well as flexible solution. Katana manufacturing ERP offers a wide range of features, from inventory management and production planning to sales order management and material purchasing, to streamline end-to-end manufacturing operations. Katana has multiple plans to suit your business size and maturity level. It also provides an implementation package (at an extra fee) to get you up and running quickly.

The Goal of this application is to provide a testing unit and a MVP solution allowing you to track work order quantities from the shopfloor, as well as complete work orders. This solution and connector can be extended with more features using Tulip’s app editor and connector framework.

Purpose

We are going to highlight different connector functions that can be built by doing HTTP calls to Katana MRP’s API to interact with the data & perform basic CRUD operations on Katana. The connector functions used for the connector let you pull a list of Work Orders, Update Work Orders, etc

API Docs

Katana MRP API Documentation

Overview of Katana MRP APIs on Youtube

Pre-requisites

Have Katana account and generate a live API key:

- Log in to your Katana account

- Go to Settings > API

- Select Add new API key

Tulip Connection Details

The following information would need to be configured on Tulip’s

Connectors.

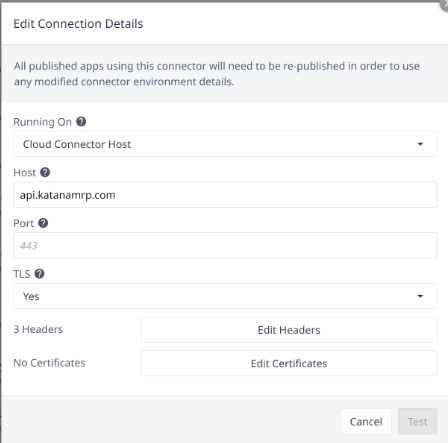

First, in the connection details:

- Running on: Cloud connector host

- Host: api.katanamrp.com

- Port: 443

- TLS: yes

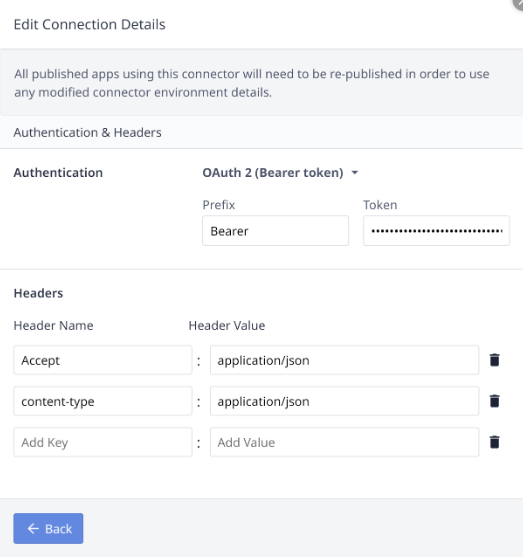

Then, in the headers view:

- Select “ OAuth 2 (Bearer Token)

- Prefix: “ Bearer”

- Token: enter the API key retrieved in the previous step

- Add a header with name “Accept” and value application/json”

- Add a header with name “content-type” and value “application/json”

Connector Functions

List all manufacturing orders - source

Returns a list of manufacturing orders you’ve previously created.

The manufacturing orders are returned in sorted order, with the most recent manufacturing orders appearing first.

Method

GET

Endpoint

https://api.katanamrp.com/v1/manufacturing_orders

Parameters

N/A

Outputs

The connector function returns the details of the work order, here are a few of those fields:

Work Order ID

Work Order Number

Variant

ScheduledStartDate

Due Date

Work Order Status

Planned Quantity

Actual Quantity

Completed Quantity

List all manufacturing orders by status - source

Returns a list of manufacturing orders you’ve previously created.

The manufacturing orders are returned in sorted order, with the most recent manufacturing orders appearing first.

Method

GET

Endpoint

https://api.katanamrp.com/v1/manufacturing_orders?status={status}

Parameters

Status: (text) one of the standard statuses known to Katana MRP (NOT_STARTED, BLOCKED, IN_PROGRESS, DONE)

Outputs

The connector function returns the details of the work order, here are a few of those fields:

Work Order ID

Work Order Number

Variant

ScheduledStartDate

Due Date

Work Order Status

Planned Quantity

Actual Quantity

Completed Quantity

Update a manufacturing order - source

Updates the specified manufacturing order production by setting the values of the parameters passed.

Method

PATCH

Endpoint

https://api.katanamrp.com/v1/manufacturing_order_productions/{id}

Parameters

OrderID : (integer) work order id

Status: (text) New work order status

Actual Quantity: (integer) new work order actual quantity

Outputs

The connector function returns the details of the work order, here are a few of those fields:

Work Order ID

Work Order Number

Variant

ScheduledStartDate

Due Date

Work Order Status

Planned Quantity

Actual Quantity

Completed Quantity

Retrieve a manufacturing order production - source

Retrieves the details of an existing manufacturing order production based on ID.

Method

GET

Endpoint

https://api.katanamrp.com/v1/manufacturing_order_productions/{id}

Parameters

Order ID : (integer) work order id

Outputs

The connector function returns the details of the work order, here are a few of those fields:

Work Order ID

Work Order Number

Variant

ScheduledStartDate

Due Date

Work Order Status

Planned Quantity

Actual Quantity

Completed Quantity