Imagine you’re a quality manager who’s noticed a consistent defect of an item in each product over the last month. Because you’ve been manually compiling quality inspection information into a spreadsheet and assessing the data, it took a few weeks to realize that there was an issue with the machine itself. While you’ve identified the issue and implemented repairs, you’re frustrated that it took so long to detect in the first place. A paper process will always require more manual labor and time, but a digital quality inspection process can analyze information in real time. By implementing quality inspection apps at your facility, you start immediately flagging anomalies, which results in reduced downtime and scrap rates and improved yield.

Quality inspection involves guidance on proper evaluation of parts, sub-assemblies, and products against a standard. This use case can help you identify root causes with quality issues to drive process improvements.

Quality inspection can identify many opportunities to improve your process. See the table below to understand how applications can support your quality goal.

| Goal | How to Achieve |

|---|---|

| Improve data integrity, Automate data collection | Automatically capture data into tables and completions |

| Detect defects | Error proof and automatically catch anomalies with alerts and spec requirements |

| Drive process improvements | Visualize areas of the process and identify which ones perform below expectations |

| Identify root causes | Organize defect types and locations into a pareto chart; collect sufficient data to support RCA |

| Compliance | Adhere to quality standards across all personas with set access privileges to apps and analytics |

| Traceability (rework) | Capture data that reveals the history to accurately report where rework needs to happen |

| Trustworthiness and reliability | Prove that you can catch defects with the results to back it up |

| Bottom line - reduce scrap | Intervene early, initiate rework loops, and improve handling of materials |

| Automate quality inspection processes | Reduce time spent on data entry and re-entry, and reduce the likely of paperwork errors |

| Quality control | Employ better management overall when all personas who need visibility can have it immediately |

Impact and Requirements

Traditionally, companies either have a manual quality inspection process or a rigid process built into their MES. Both methods can be painful when it comes to managing updates, analyzing data, and reducing human errors.

Digitizing quality inspection is a scalable and sustainable approach that can be easily adapted for new products or processes.

-

Quality escapes

Inevitable human errors mean quality escapes are bound to get through an inspection process if not flagged. When moving through quality inspection apps, you can create and send defect reports for any failed inspection. This ensures information reaches the right people before customers receive the products. -

Reduce cost of quality

If your quality process takes significant time, and therefore has a high cost, quality inspection apps are a great solution to mitigate those issues. Streamline the process with automatic data collection, reusable processes, and analyses that reveal areas to focus and improve efforts. -

Scrap reduction and yield improvement

Use quality inspection app data to draw attention to where issues are. Visualizing data with analyses automatically show insights that otherwise must be manually calculated with a paper process. For example, these insights can lead to investigating scrap issues in order to increase yield. Make quality improvements that save time and costs.

Any industry can benefit from deploying quality inspection apps, but they are especially ideal for scenarios with high cost of goods and high value materials. Additionally, any operation with high variation from piece to piece can be prone to mistakes and therefore gain significant value.

This use case is an ideal starting point for quality solutions because it’s easy to implement from manual inspection. Quality inspection is scalable and offers quick value. You can also use minimal ERP and device integrations.

How to Get Started

Before you build an app, it’s important to obtain a snapshot of your current inspection process and decide where you want to go. Complete the following steps in order to ensure success:

-

Capture baseline quality data. Taking note of the current state allows you to measure improvements from your starting point. Get quick-to-value digital insights to inform KPIs and improve business value.

Ex. current pass/fail rates, current count of defects by reason code, etc. -

Agree on measurable business objectives. What areas of quality are you concerned with? What do you want to see improve? What are the goal metrics you want to hit?

Ex. Reduce time spent dispositioning -

Determine the personas involved and capture high-level user stories. Who does quality inspection concern and how do they benefit? This information will inform the various functionalities within the app, what data needs to be captured, and what you need to do with that data.

Ex. Operators need to log quality events so they can be reviewed and dispositioned, Supervisors need real-time visibility into quality events, Quality team needs ability to review and disposition quality events

App Architectures

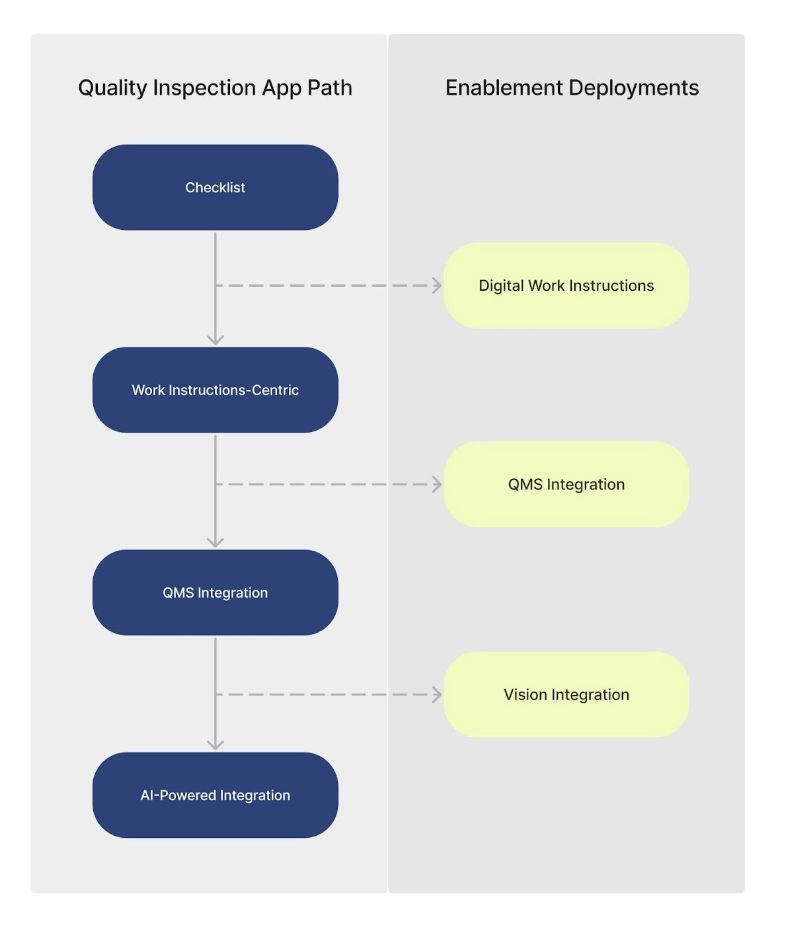

Once you complete the above steps, you can start app building. Because quality inspection can take different forms, there are multiple ways you can create apps to go through this process. Start with a simple app and iteratively build in more complexity, including integrations. Let’s go through different types of apps with variations in complexity and features.

Checklist App

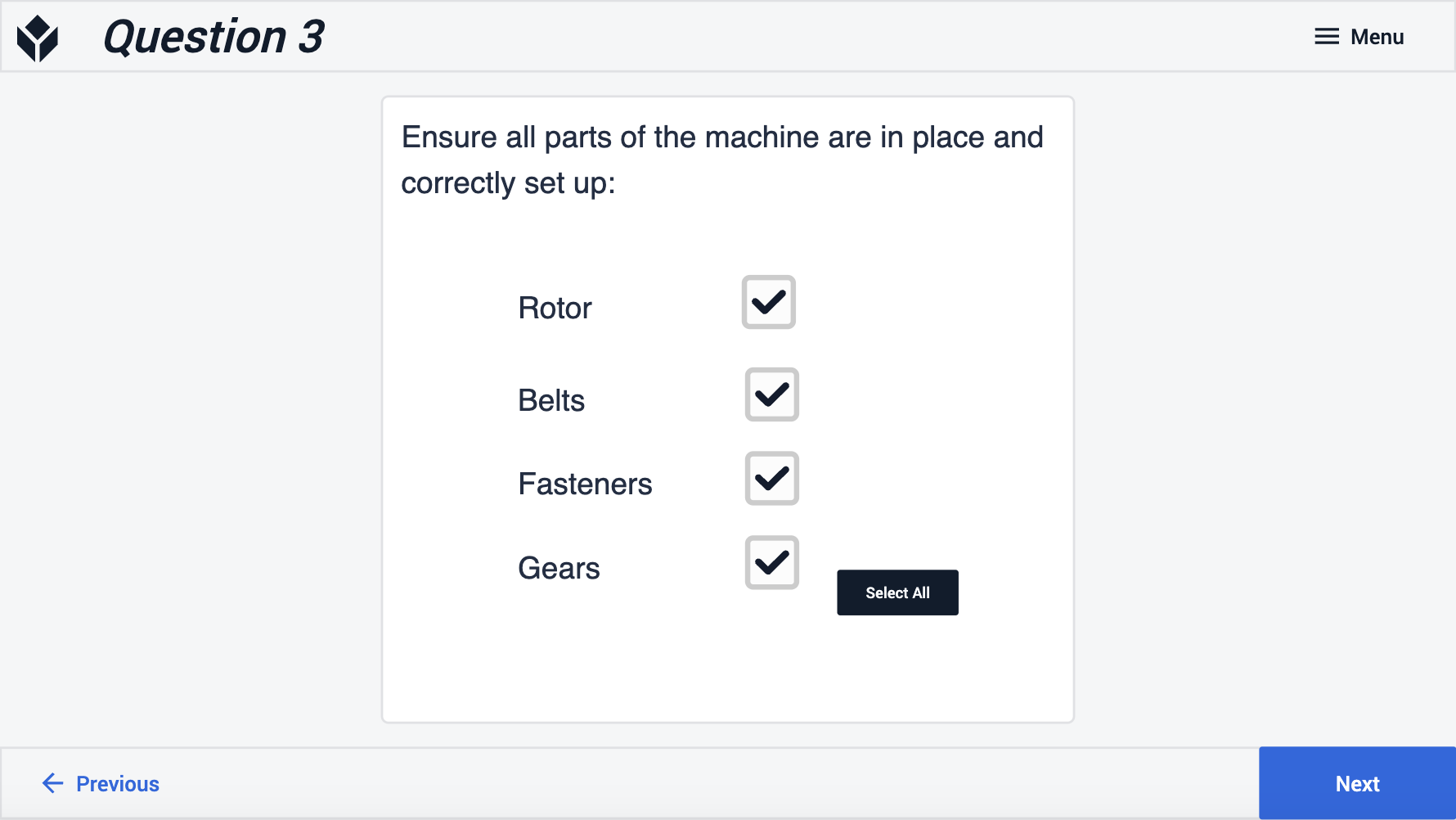

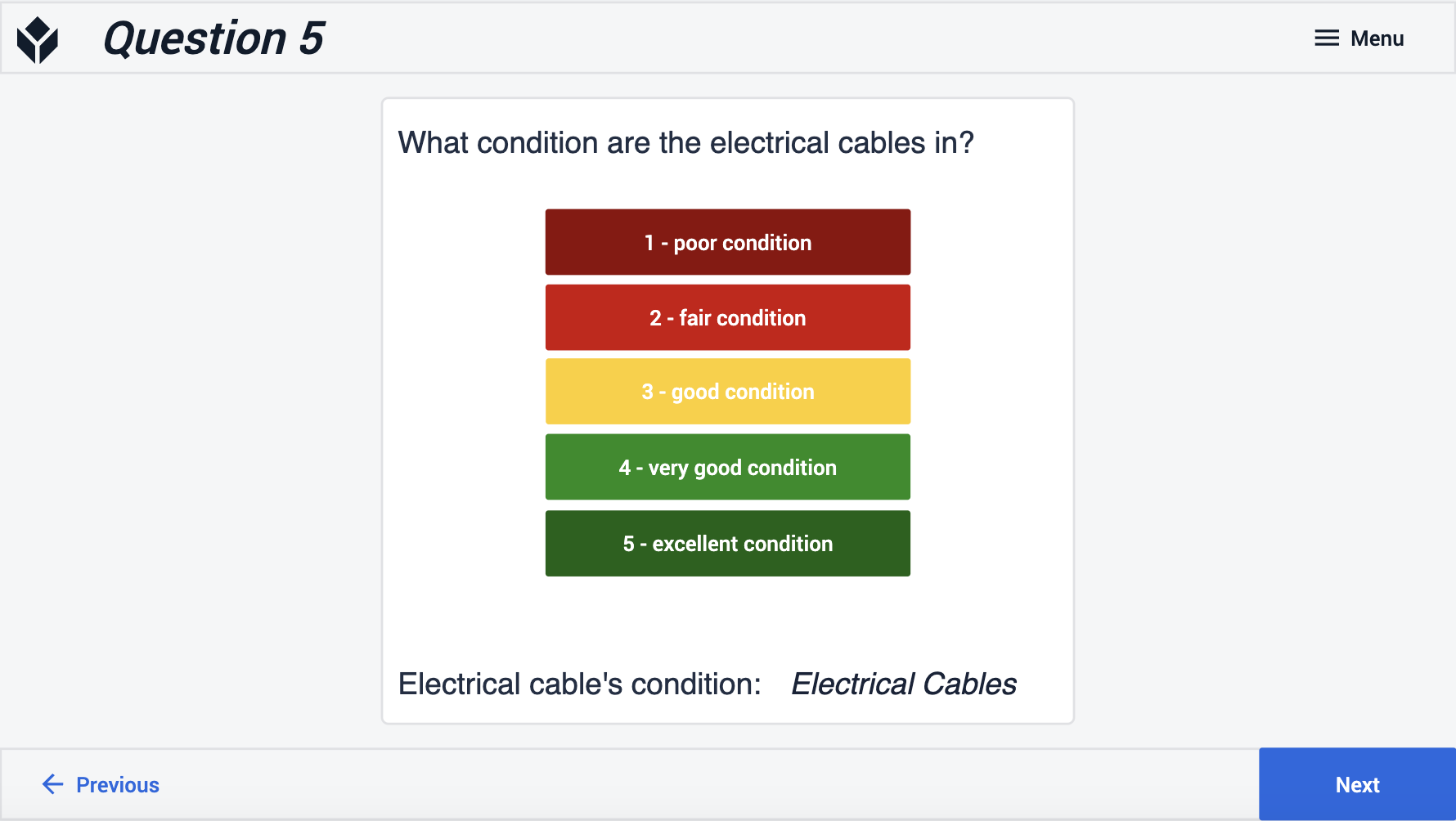

The simplest and quickest way to deploy a quality inspection app is to create a checklist of your inspection process. This looks like a series of steps that ask questions or collect information. Capture data through Variables or Table Records, then visualize the data with Analytics.

Work Instructions-Centric

Integrate quality checks into a work instructions app that uses existing Completion records. This model replicates a step-by-step instructions flow for inspection.

QMS Integration

Integrating with a QMS, such as Arena, allows for more advanced statistical processing. Use data that you already have and get advanced statistics for your analytics.

Check out the QMS App Suite available in the library.

AI-powered with Vision

Automated visual inspections rely on visual data to make assessments. With machine-based analysis, they offer a way to substitute human visual judgment. This method requires integration with Tulip Vision, which is recommended for advanced users.

The deployment path below shows how you can progress from one quality inspection method to another by integrating other use cases and features into your app architecture.

Best Practices

Review Tulip’s data collection methodology.

It’s important to differentiate when to store data in a table vs in completion records. For example, quality events are an operational artifact and should therefore log into a dedicated table. Cycle times and app operator data should be stored into completion records.

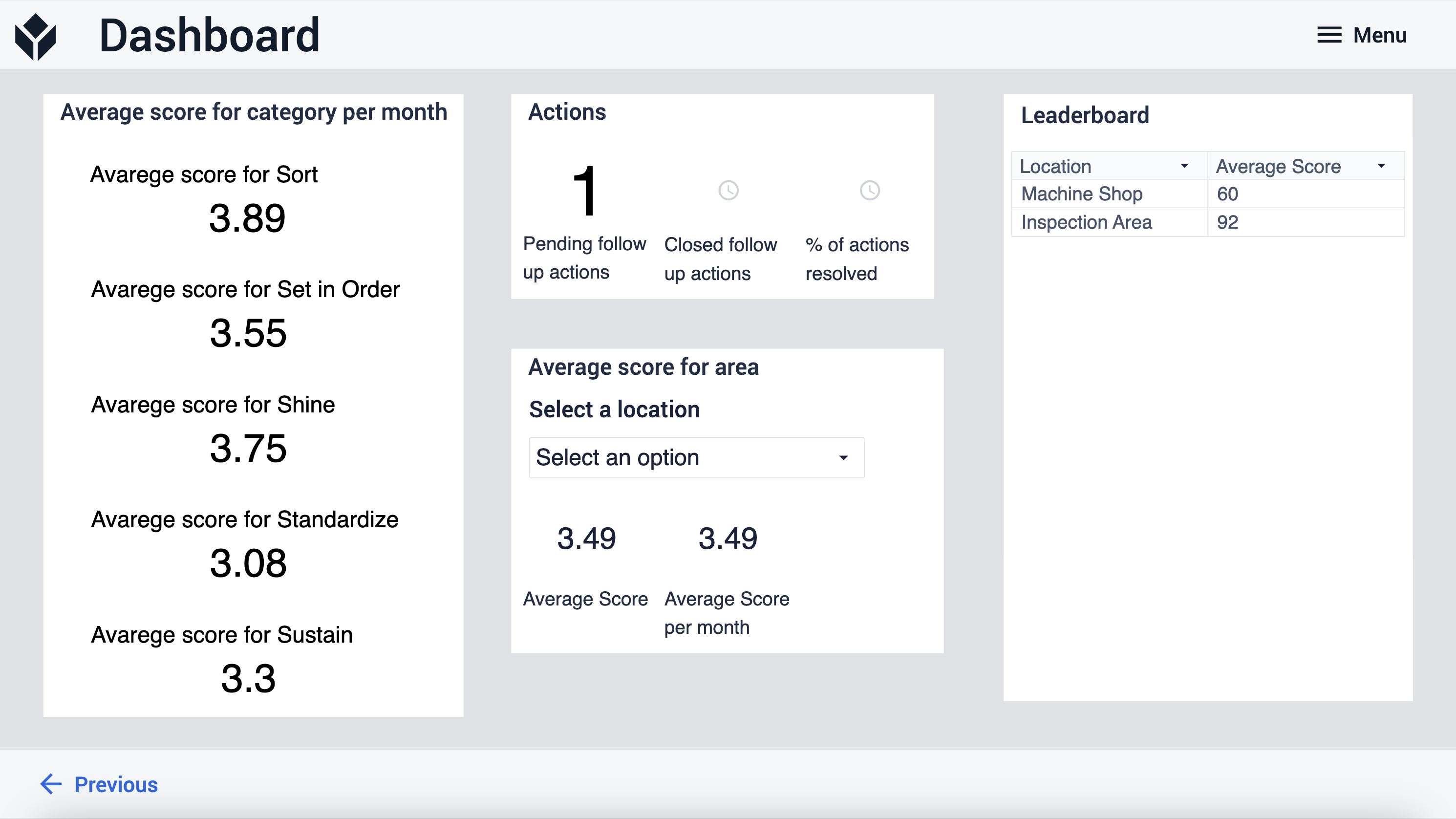

Provide real-time visibility to all personas via Analytics.

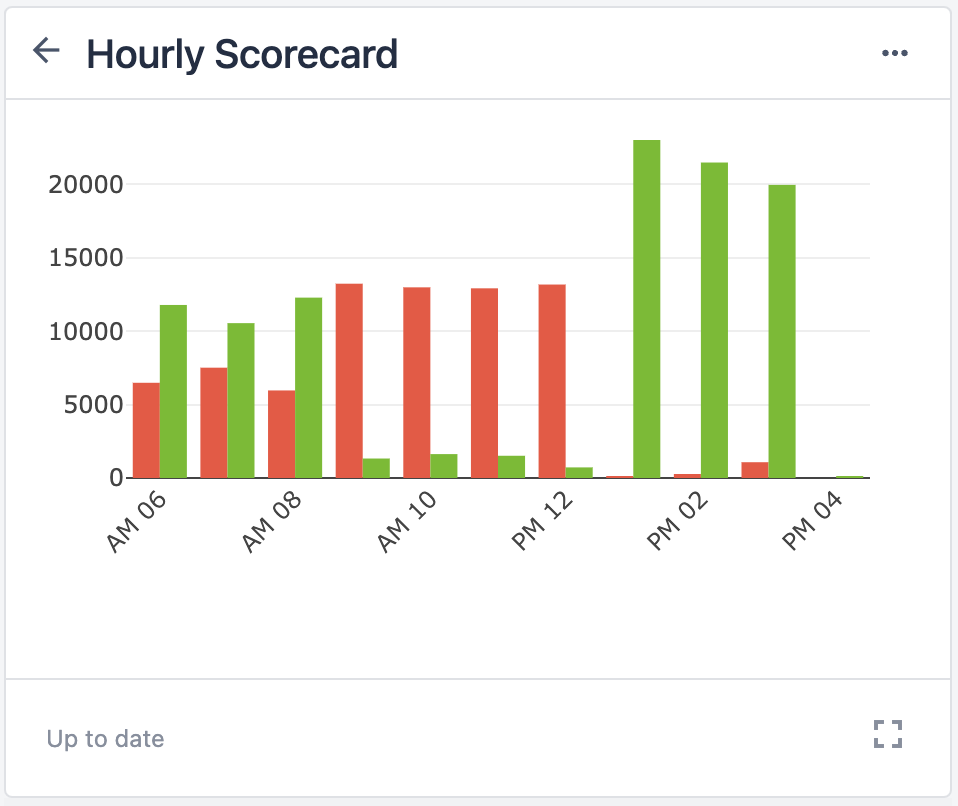

Visualize your data to determine if you’re meeting your business goals and drive continuous improvement. Each persona has particular information relevant to their process. Create dashboards that provide insights and compile a picture of current state.

Tulip Resources

Whether you want to learn more about Tulip features to build quality inspection apps or you want to use Tulip’s ready-made templates, we have the tools to help you get started.