Imagine you’re a production supervisor responsible for final packaging before shipping products to customers. On average, the process takes fifteen minutes per box, spent gathering information, packing, and inspection, and more time if the box is incorrectly packed. To decrease cycle times and labor costs, you begin using a pack and ship app. The app expedites the process, from viewing work order details to printing shipping labels to automatically inspecting the packages for correct items. After digitizing the pack and ship process, you start seeing fewer packing errors and detailed packing slips with full end-to-end traceability - leading to higher customer satisfaction.

A pack and ship process ensures the correct products are in the right boxes and sent to the correct customers. This provides traceability which can ensure customer satisfaction and allows the company to recognize revenue on time.

The table below provides a breakdown of goals you can achieve and who will benefit.

| Goal | How to achieve | Who benefits |

|---|---|---|

| Full end-to-end traceability | Automatic data capture to compile a complete historical log | Production management, customer service representitives |

| Less paperwork | With a digital system, you automate processes previously done by hand and digitally store information so you don’t need to print everything | Shipping supervisors, administration |

| Accessible product info | Store information in barcodes that require scanning to access | Shipping supervisors and operators |

| Easy-to-access shipping info | Information stored digitally is easily accessible | Customer service representatives, Sales teams, customers |

| Decrease human error | Clear guidance using Vision to detect correct packing | Shipping operators, Quality inspectors, Customer service representatives |

Impacts and Requirements

Traditional approaches to pack and ship are manual and tedious. Operators need to switch between multiple screens to understand proper packing. Digital pack and ship methods provide the operator with a streamlined, error-proof workflow, including clear packing instructions and information about the order being packed.

There are two significant areas digital pack and ship apps help:

- Reduce errors - Errors such as incorrectly sent products, missing parts, quality issues, incorrect ERP info, etc. can erode consumer trust and lead to warranty issues. Measure errors with data on return/warranty claims and costs. Photo documentation of products before they left the shop floor helps to identify root cause, ensure accountability with customers, and prevent workers from making errors

- Reduce labor costs - The time it takes to complete tasks can decrease with digital technology. Simply automating shipping labels reduces the process time from several minutes down to a few seconds. Measure the savings with cycle time data automatically collected in apps.

Any industry can benefit from pack and ship apps. Ideal production types that benefit are high-mix, low-volume, especially those built-to-order or involving large units. Operational details such as variation, customization, and large parts are more prone to errors, which pack and ship apps can mitigate. Productions that have low-mix, high-volume can simply avoid costly mistakes that can come with rapid production.

This use case can be can simple to deploy with beginner Tulip experience and create high impact. Minimum set up involves basic app building, data collection with tables and completion records, trigger logic, and plug-and-play barcode scanners. Using barcode scanners creates an easy and intuitive experience for operators that expedites capturing data. You can extend an app by using Tulip Vision, to automatically verify correct packing, or integrating with an ERP to pull information.

How to Get Started

Before you begin building pack and ship apps, it’s important to capture what operators need by completing the following:

- Understand the change of Status in a Work Order

- What are the states of a work order?

- At what step in the process can the state change?

- Record data that needs to be captured (weight, size, etc.)

- Establish the work order details you need to show

- What information do you need to keep a record of?

- What information do you need to send to customers?

Once you gather the information above, you’ll have a clear picture of the guidelines operators need to follow and the information the app should collect and compile for traceability.

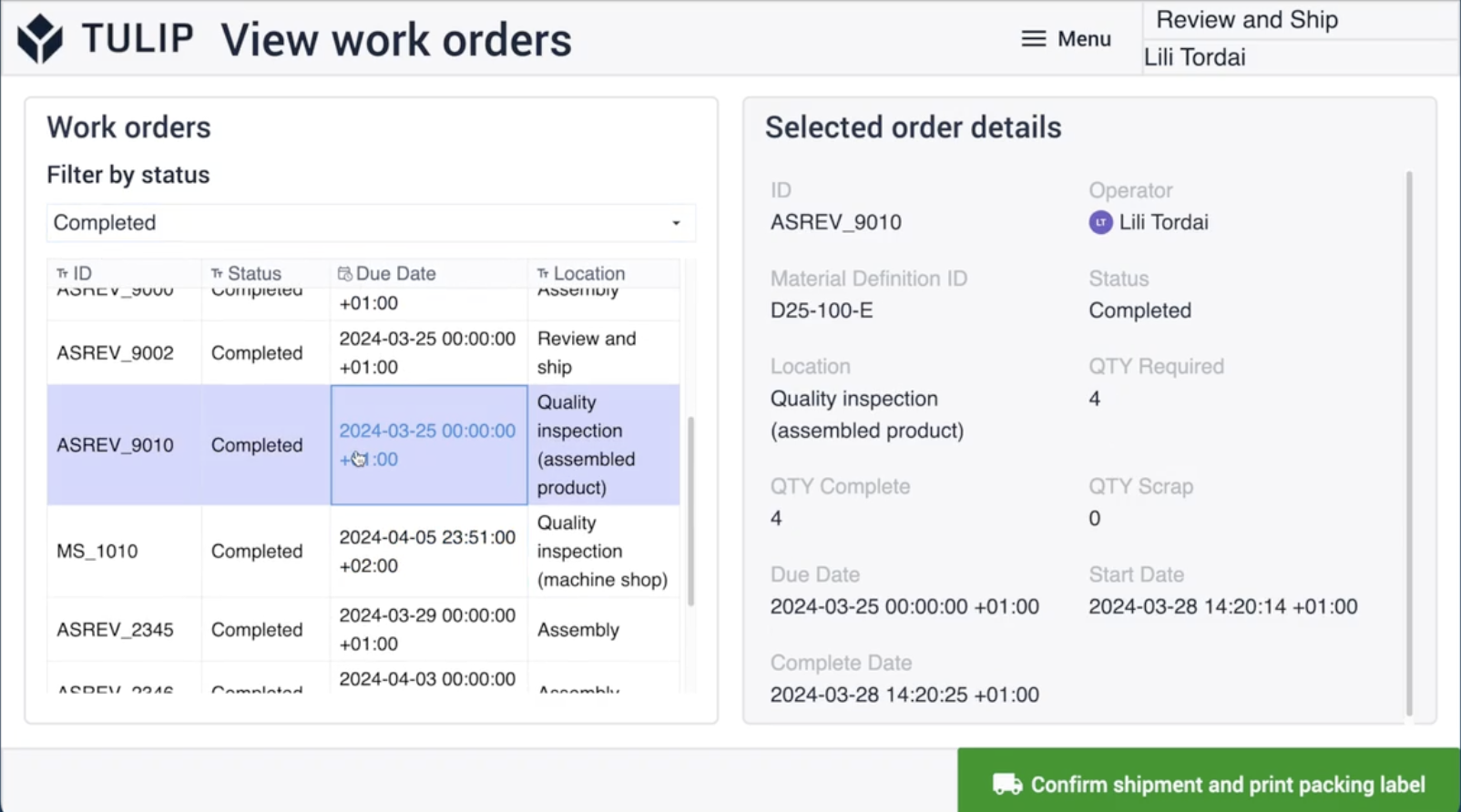

Building a pack and ship app doesn’t need to be complex. The main functions it needs to have are:

- Work order information

- Packing label with traceable information

These functions should be separate steps to ensure operators have clear procedure guidance. For example, on Step 1 an operator selects a work order and views the order details. On Step 2 a packing label is created that includes the work order ID, product information, operator ID, and the date it was packaged.

Additional functions can include:

- Detailed packing instructions

- Package weight and specs

The most important feature to have in your app is a table for work orders.

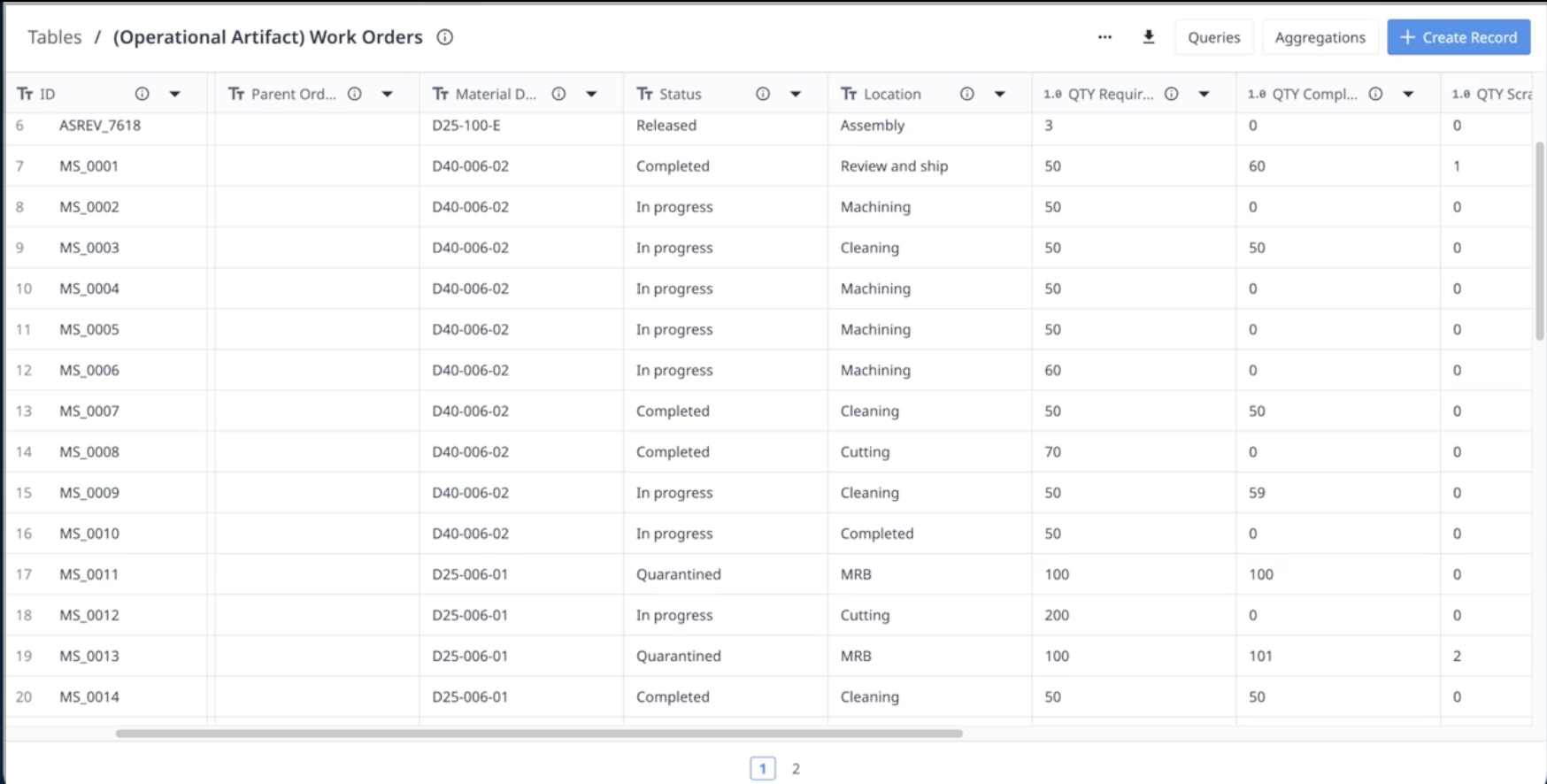

Work Orders Table

Use a common work orders table to store centralized information regarding each work order. This table can include fields for quantity, location, packing materials, and shipping status. Your pack and ship app should pull from this table to display all relevant information for each order.

Display work order information with an interactive table, and then use a table record widget to display the details of a selected work order.

Integrating Devices

Connecting devices to use with your apps creates a seamless and intuitive experience for operators moving through the process. The following devices are commonly used with a pack and ship app:

- Plug-and-play barcode scanner

- Printer integration

- ZPL viewer widget

- Scale integration

When you become more advanced with this use case, you can use Tulip Vision to automatically inspect boxes for properly packaged materials.

Note that you don’t need to integrate devices on your first app version. Start with a simple app, deploy it, and iteratively build in more complexity. Use devices as you see fit to assist the operator and help contribute towards process goals.

You can take this use case further by integrating it with other process apps that use the same data. For example, work instructions and order tracking can pull data from the Work Orders table. A weigh and dispense app can provide measurements for each item.

Tulip Resources

Whether you want to learn more about Tulip features to build out digital pack and ship or you want to use Tulip’s ready-made templates, we have the tools to help you get started.