To download the app, visit: Library

This Article summarizes how the Mobile Production Scorecard with Takt time application is structured and built.

Purpose

The application provides a simple solution for manually logging machine activity and displaying real-time yield and takt time calculations. Users can easily switch between the machine's statuses and log both good and bad parts during production.

Tables Used

The Table used in the application is called Station Activity History. Each Record in the table is a station activity event that has a status. When using the application, data is logged in this table. The user can view the analysis of the table’s data on the Analytics step.

Fields of Station Activity History:

ID: the unique identifier of each event

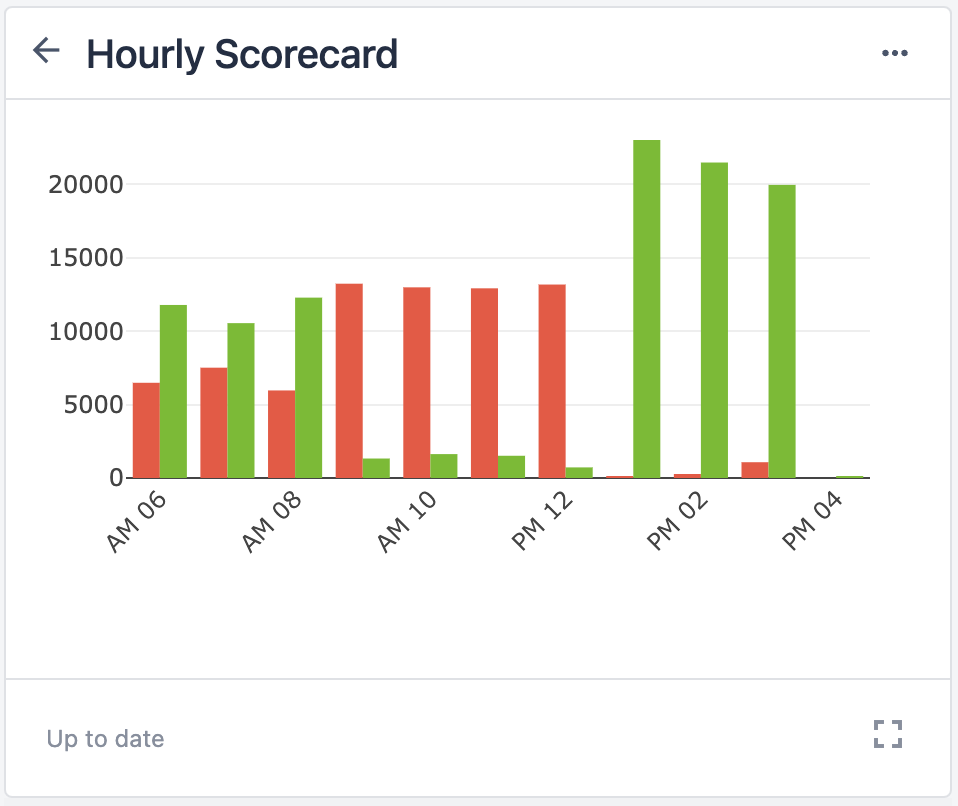

Hour Block: the hour where the event occurred, can be used to create hourly scorecards

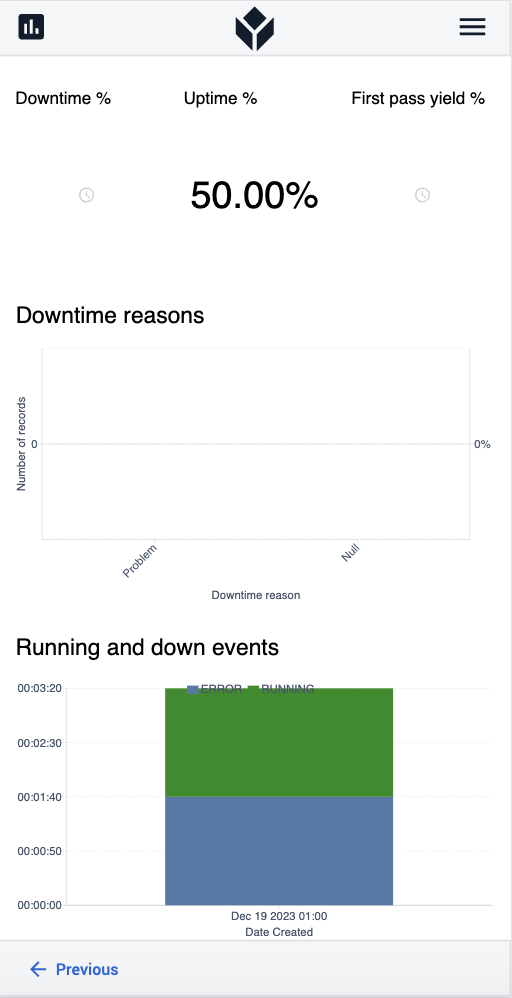

Status: the status of the event e.g.: RUNNING, DOWN, OFF

Downtime reason: if the status of the event is DOWN, the user can select the reason for the downtime which will be stored in the downtime reason field of the record

Duration: the time interval of the event

Station: the station on the shop floor where the event occurred

Actual: number of good parts produced during the event

Target: a target number of products that is calculated automatically from the duration and the event and the manually predefined production rate

Defects: number of bad parts produced during the event

Product ID: the unique identifier for the product type made during the event

App Structure

In the app, there are two queries that each have a pair of Aggregations. For the first query, With Order ID, we've incorporated the Sum Actual and Sum Defect aggregations. These are utilized to calculate the yield during the logging of both good and defective parts.

The second query, Today's Running Event at Station, comes with the Duration of Today's Event and Actual of Today's aggregations. This specific query aids in determining the cycle time when logging both good and defective parts.

We have utilized the Order ID as a filter for the With Order ID query. Users can add this on the first step. For the Today's Running Event at Station query, filters include the Order ID, Start of Production Variables (with Order ID specified on the first step, and the Start of Production as a variable capturing the current date and time upon app entry), App Info: Station Name, and a static value RUNNING

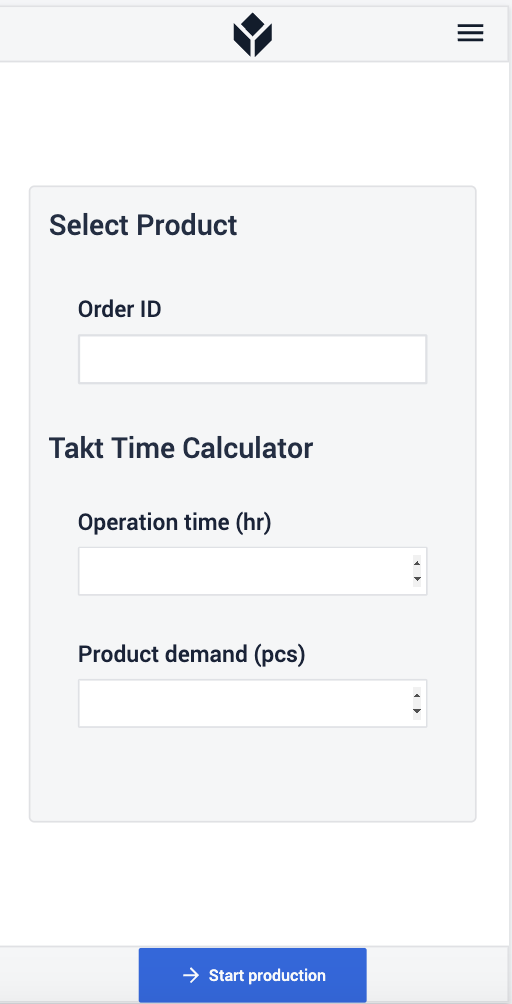

In the first step of the app, users can input the Order ID. For takt time calculation, unlike with other performance visibility apps, users need to provide an operation time in hours and the product demand number for that specific time period.

When users click on the Start Production button, the app will navigate to the next step and create a record in the Station Activity History Table. Additionally, it'll store the production rate and the planned takt time - which are calculated from both the operation time and the product demand - into two separate variables

On the Main step, the user switch between production statuses and they can also log good parts and defects. If the selected status is DOWN the app navigates the user to the Change status to down step where they must select a downtime reason to proceed.

During a Machine Status Change, the app references a variable called No Target Statuses. Users can set the default value for this variable in the Variables - Default Value section of the app's side menu.

The importance of this variable lies in its function: if a status is included in this variable, the app will not log a target for the duration of that status period.

Currently, we have set it up so that the variable only contains the

OFF status. This means that if we change the status of the machine to OFF and later we change it to a different status, the app will not calculate a target number for that downtime period.

This step involves four variables: Product Demand (which is the Target), Yield, Planned Takt Time, and Cycle Time.

The Planned Takt Time and Product Demand are calculated in the first step when the user clicks on the Start Production button. These values will not be recalculated. The Cycle Time is recalculated every time good parts are logged. Similarly, the Yield is recalculated every time either a defect or a good part is logged.

The Analytics step can be reached from any of the other steps. The user can view Analyses about the performance of the production

Related Apps

- For managing performance across multiple stations, check out the Centralized Performance Visibility Scorecard

- For alternate designs, check out the Hourly Production Scorecard

.gif)