Contextualize data from Tulip Lean Daily Management boards with systems of record to gain better insights on operational improvements

Purpose

Lean Daily Management boards are crucial to enable visibility at the cell, line, and plant level. It's also critical to rigorously drive meetings on all three levels (cell, line, and plant) to easily escalate issues as needed.

It's also important to make these meetings as data-driven as possible.

Learn more with our article all about Lean Daily Management here

Lean Daily Management meetings can typically revolve around an SQDC board (Safety, Quality, Delivery, Cost) board such as the one below:

There are two significant improvements that can be made with Tulip and AWS:

- Digitize Lean Daily Management boards with Tulip apps to streamline metrics capture and recording escalation actions

- Stream the Lean Daily Management app data to AWS where it can be further analyzed in the context of engineering, supply chain, and other enterprise data.

These two improvement areas for lean daily management boards create the opportunity to more concretely create actions that matter as well as broader enterprise-level improvement opportunities rooted in manufacturing data from the shop floor.

Examples can include engineering redesigning parts based upon operator feedback and more.

Architecture and Setup

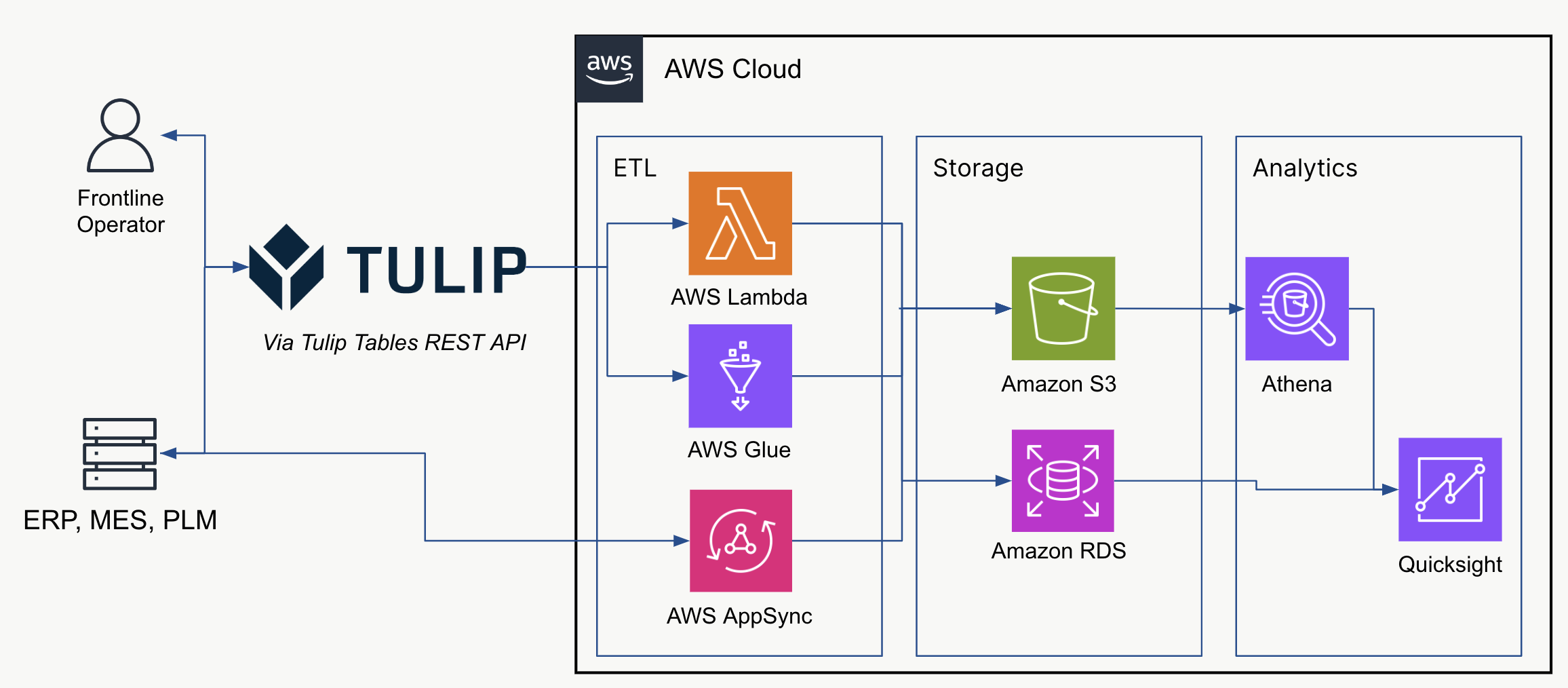

The architecture has several options based upon the data ingestion and storage requirements.

Below is a sample architecture to get started:

Let's walk through it step-by-step below

Data Creation

Tulip apps are used to manage the lean daily management meetings. Apps such as the Lean Dashboard app on the library can be used for this purpose.

This enables supervisors to clearly capture shop floor level details and store in either completion records or Tulip Tables

Data Ingestion

Data analysts can either use a simple lambda function to query data from Tulip or a more robust script on Glue ETL. It can depend upon existing experience as well as workload requirements. If data cleanup is required, Glue ETL may provide more options.

This guide on querying tulip table data from an AWS lambda function can apply to both options

For ingesting and contextualizing ERP and other enterprise data, a variety of options ranging from REST APIs and Glue ETL / Lambda to using AWS AppSync exist.

Optionally, machine data can be captured from IoT Sitewise or IoT Core for further shop floor context.

Data Storage

The data from Tulip and other enterprise systems can be stored in a number of options. Below are some examples:

- Relational Database: an existing relational database (e.g., AWS RDS) can be used to store lean daily management data and then analyze on your Business Intelligence (BI) tool of choice

- Data Lake: S3 in conjunction with Glue and AWS Athena can also be used to easily store data without using a data base and then query it with Athena in a serverless fashion

- Data Warehouse: many other options such as Redshift also existing depending upon your data restrictions, volume, and other considerations.

Data Analytics and Visualization

As a simple starting point, insights can be analyzed on Bi tools such as Amazon Quicksight, PowerBI, and Tableau.

Beyond this, the lean daily management information can also be analyzed at a more granular level with tools like Sagemaker notebooks if deeper analytics are required.

Example Value Creation

Supply Chain and Engineering Feedback

By analyzing lean daily management data alongside supply chain and engineering data, you can understand if the root cause of a defect issue or delivery problem may be result to broader issues in the supply chain or within the product designs themselves. Contextualizing data across the shop floor (Lean Daily Management), Supply Chain, and Engineering allow for this broader analysis

Benchmarking

Aggregating lean daily management data across multiple lines, sites, and business units enables easier benchmarking to understand top performing cells and understand how to best relay leading practices across the entire enterprise

Next Steps

Once you've mastered this initial architecture, layering in insights from machine IoT data is a great next step to paint a full picture of shop floor performance.

Additionally, check out the Fetch all Tulip Tables Article for more context on properly fetching all data from Tulip