Dynamic testing app VS Composing quality inspection apps

Many operations still rely on traditional methods such as paper documents, Excel spreadsheets, or other outdated systems to manage work instructions and inspections. However, digitizing and validating all procedures can be time-consuming, requiring careful planning and execution. When digitizing quality processes, organizations have two primary options: dynamic testing apps or composing guided inspection apps.

Dynamic Testing App

A dynamic approach offers a more generic and rapid solution. It loads corresponding data from tables into a generic app, allowing for efficient use. This method is particularly useful when dealing with a large variety of mostly similar products, as it eliminates the need to build individual apps for each process. It streamlines operations by reducing redundancy, but is not very flexible in taking into account differences in the process flow.

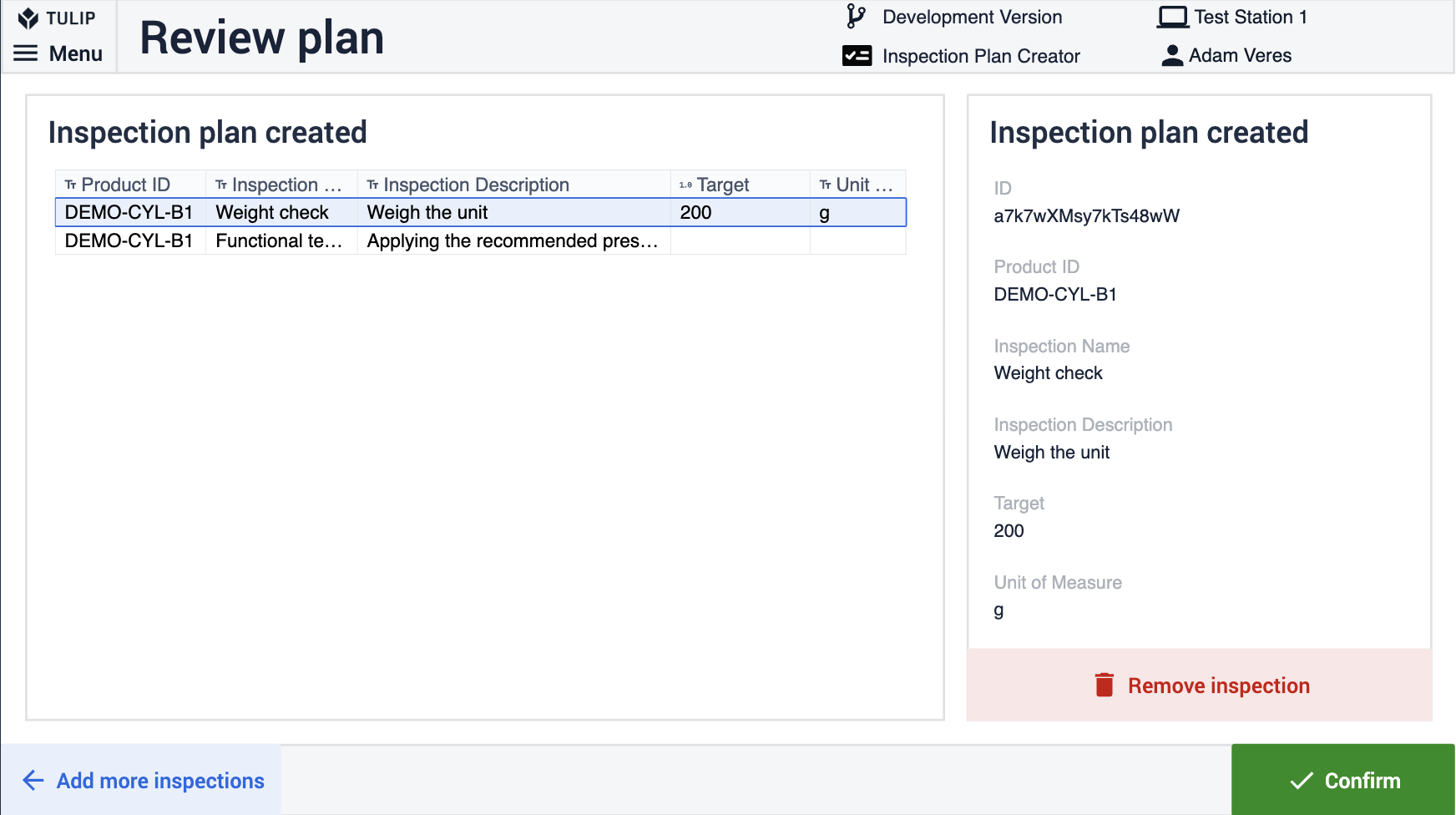

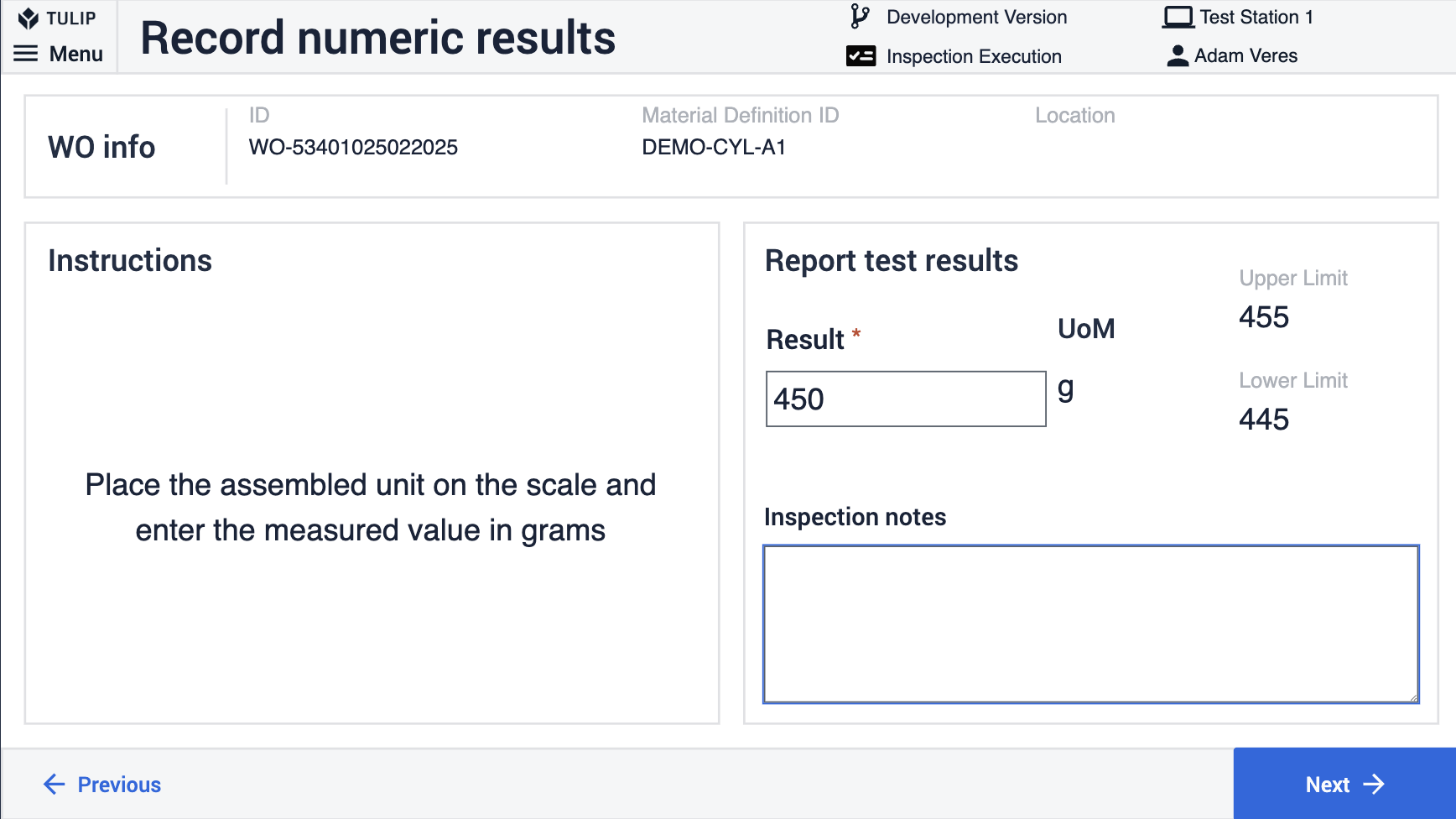

There is an example for this approach using the Inspection Plan Creator and the Inspection Execution app. The Inspection Plan Creator (and an automation) populates the Inspection Results table with the details of the required inspections (pass/fail or numeric) for a specific product unit. The Inspection Execution app is then loading the required inspections for the selected product unit from this table and displays the details for the operator dynamically on the pass/fail or the numeric inspection step.

This approach helps to ensure a consistent inspection logic and inspections can be created very quickly. However the steps are rather generic and cannot be much customized for a specific product and inspection process. It could be a good starting point to have inspections ready quickly and then add more customized inspections later gradually that allow for more differences in the process flow. It can also be a good solution for a large variety of similar products.

Composing Guided Inspection Apps

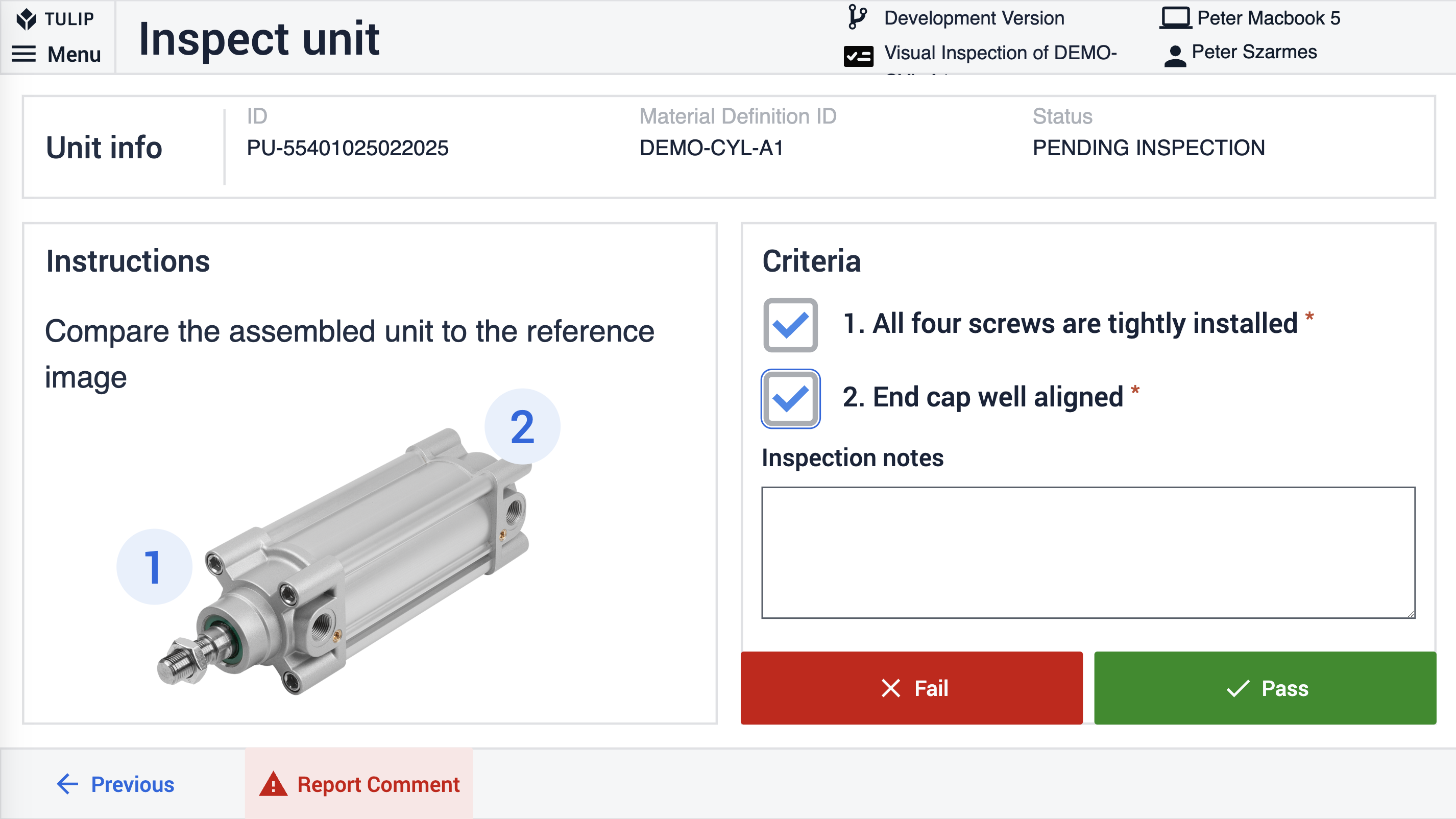

This second approach involves creating guided inspection apps tailored to specific products (or product families). These Tulip apps provide greater flexibility and a more user-friendly interface, ensuring that each step is clearly defined and easy to follow. While this method requires more effort upfront, it results in better usability, process adherence, and a structured workflow that minimizes errors.

There is an example for this approach with the Guided Inspection Template and Visual Inspection Example app. The template includes a variety of predefined steps that can be combined to create inspection processes tailored to specific needs, ensuring accuracy and consistency in quality control. The Visual Inspection Example app is built using this template. It is an app with a unique work instruction for executing the quality check for a specific product. It allows for greater flexibility and a more user-friendly interaction. In this case the Inspection Execution app can be used as a navigation app to jump into the corresponding guided inspection based on the selected product unit.

This approach could be used more in the highly regulated industries (e.g., medical devices, aerospace, and automotive) where compliance and traceability are critical. It is also important in cases of complex quality control processes that require detailed step-by-step instructions to minimize human error. This solution has the advantages that it can be highly customized to specific product or process requirements, and it is more user-friendly with guided workflows, ensures better compliance and traceability. The disadvantages are that it is more time-consuming to build, deploy and maintain (compared to the dynamic approach), and less scalable for operations with a wide variety of products and processes.