Introduction

zenon est une plate-forme logicielle développée par COPA-DATA, principalement utilisée dans le domaine du contrôle et de l'acquisition de données (SCADA), de l'interface homme-machine (IHM), de l'orchestration de processus (MTP POL) et des systèmes d'historisation.

zenon offre un ensemble complet d'outils de visualisation, de contrôle des processus et d'acquisition de données dans les environnements industriels. Il permet aux utilisateurs de surveiller et de contrôler divers processus et machines en temps réel, en fournissant des informations sur les processus de production, la gestion de l'énergie et le contrôle de la qualité.

FrontWell Solutions{target=_blank} a créé un connecteur et une application Tulip pour présenter l'intégration entre zenon et Tulip. Dans le présent document, nous allons vous guider à travers un processus généralement applicable mais simplifié d'échange bidirectionnel de données entre un système de fabrication (Tulip) et un système d'automatisation industrielle (COPA-DATA zenon).

La connexion de Tulip à COPA-DATA zenon via l'API REST présente de nombreux avantages et permet de répondre efficacement aux différents cas d'utilisation des clients dans le secteur de la fabrication. Vous trouverez ci-dessous une illustration centrée sur le client qui met en évidence les avantages dérivés de cette intégration.

Si vous avez besoin d'aide pour réaliser des scénarios d'interfaçage plus complexes, n'hésitez pas à nous contacter.

Considérations sur le réseau

Si COPA-DATA zenon est hébergé ou accessible depuis le cloud public, aucune configuration réseau spécifique à tulip n'est nécessaire.

Dans le cas où COPA-DATA zenon est hébergé sur site, un accès approprié doit être configuré pour que la Tulip puisse communiquer via l'hôte local (par exemple, ajustement des règles du pare-feu -> "liste blanche" de l'IP de la Tulip) ou configuration de l'hôte du connecteur respectif (lien : https://support.tulip.co/docs/introduction-to-tulip-connector-hosts). Un jeton Oauth 2.0 doit être généré par Tulip.

Configuration de COPA-DATA zenon

Prérequis :

Les services IIoT de zenon doivent être installés et faire l'objet d'une licence dans la plateforme logicielle zenon afin d'activer l'API IIoT (interface REST).La version minimale de zenon prise en charge est la v.12.

Configuration :

Les services IIoT doivent être configurés dans le studio d'ingénierie de zenon. L'accès depuis l'APP externe (Tulip) doit être configuré dans le studio de configuration des services IIoT de zenon.

L'API a été construite en utilisant Swagger, et il existe une documentation détaillée et interactive de la structure de l'API. Cette documentation ouverte de l'API est disponible sur demande et peut être très utile pour construire de nouveaux connecteurs.

L'API IIoT de zenon nécessite une authentification par jeton.

En utilisant l'API IIoT, il est possible de :

- Lire les variables de processus en temps réel de zenon :

- d'écrire des variables de processus dans zenon

- Interroger les alarmes en temps réel et les alarmes historiques

- Interroger les pistes d'audit

- Interroger les données des séries temporelles.

Le paramétrage des appels à l'API REST doit prendre en compte les ressources du projet zenon, telles que l'identifiant du projet, le nom des variables, le groupe/la classe d'alarmes, le nom des archives, etc.

Pour plus d'informations sur l'API IIoT de zenon, veuillez consulter l'aide en ligne de COPA-DATA{target=_blank}. Un ingénieur zenon doit fournir des informations sur le projet afin d'appeler correctement l'API IIoT à partir d'une application tierce.

Pour plus d'informations sur la configuration et les fonctionnalités de la plateforme logicielle zenon, veuillez consulter l'aide en ligne de COPA-DATA ou accéder à la COPA-DATA Academy{target=_blank}.

Configuration de Tulip

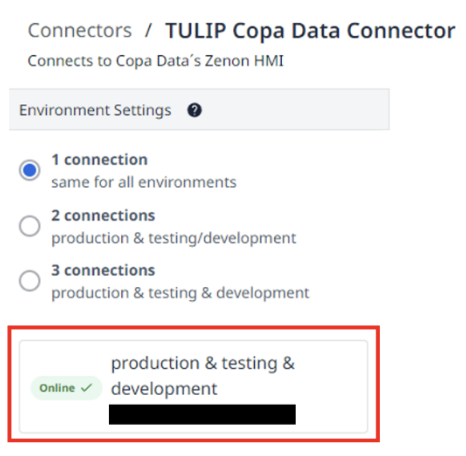

Accédez au menu Connecteurs dans Tulip et cliquez sur la configuration de TULIP Copa Data Connector.

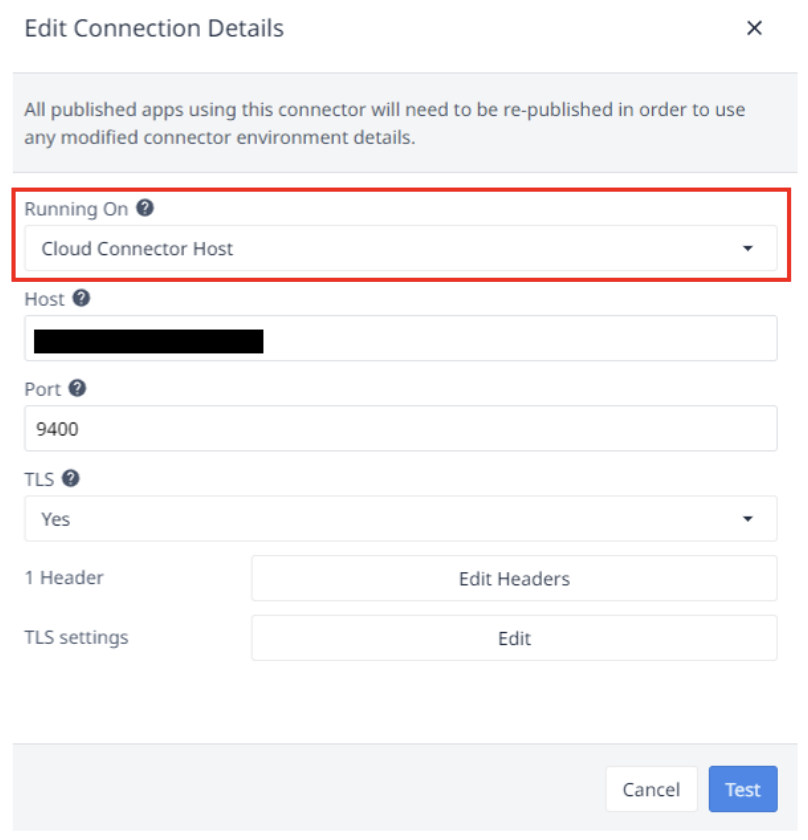

Réglez le champ "Running on" sur "Cloud Connector Host" (en fonction de la configuration de votre hôte de connecteur : https://support.tulip.co/docs/introduction-to-tulip-connector-hosts) en choisissant dans la liste déroulante.

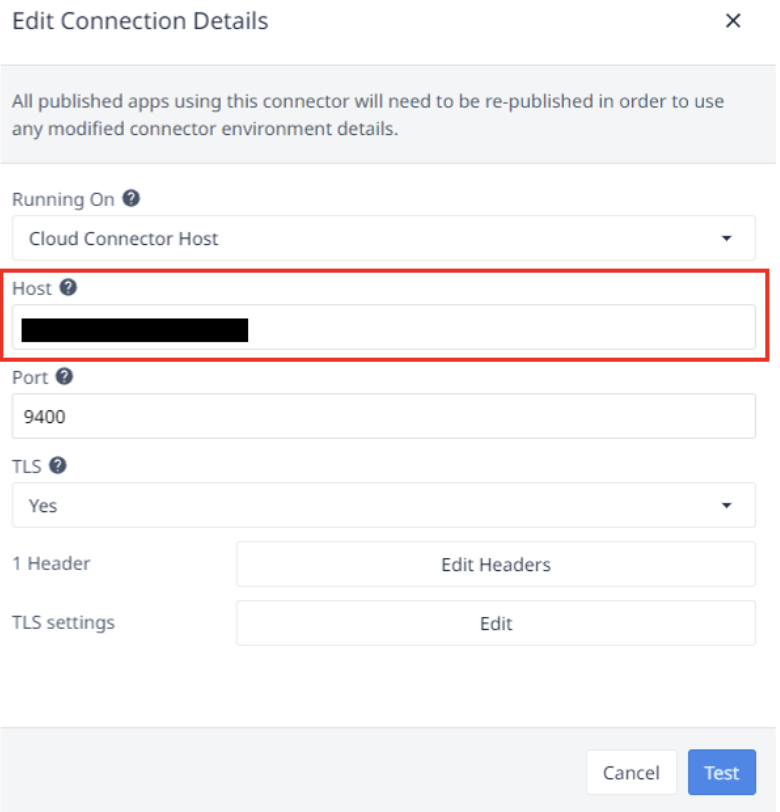

Définissez l'hôte sur l'IP de votre COPA-DATA zenon X

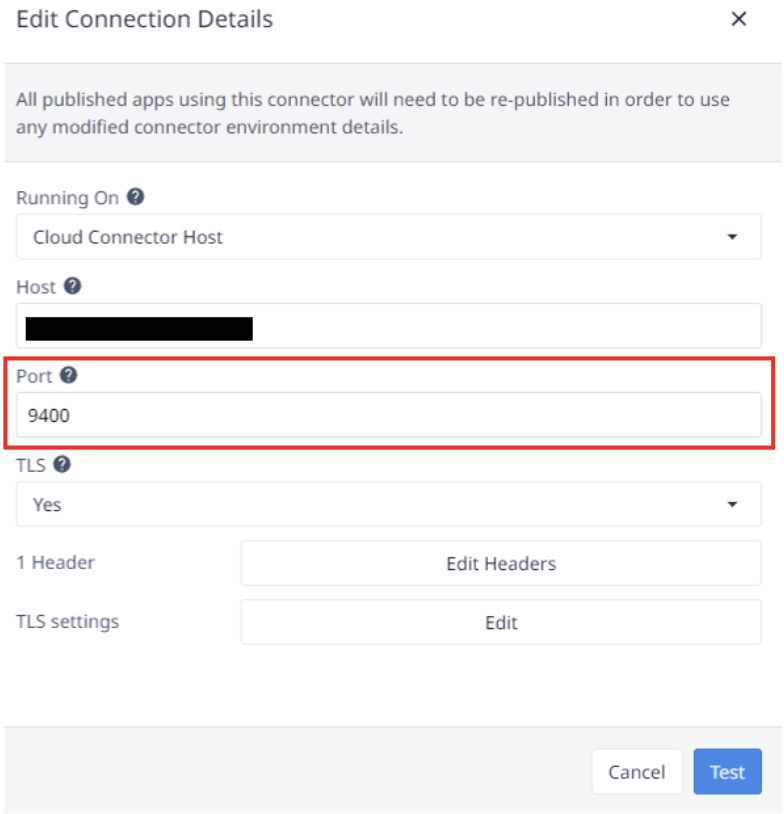

Réglez le Port sur "9400" comme indiqué dans la documentation de COPA-DATA zenon.

Il convient ensuite de tester la connexion et de s'assurer qu'elle est fonctionnelle.

Fonction du connecteur

Le présent connecteur utilise l'API REST et ses fonctions standard GET, PUT, POST et DELETE.

Les interactions génériques suivantes, liées à l'automatisation, ont été mises en œuvre dans ce connecteur. Dans des scénarios réels, des interactions plus complexes peuvent être nécessaires et peuvent être réalisées en étendant le connecteur actuel et ses fonctions. Si vous avez besoin d'aide pour réaliser des scénarios plus complexes, n'hésitez pas à nous contacter.

Fonction de remplissage et d'emballage

Selon le scénario habituel, le système de fabrication est le maître de la gestion des ordres de travail (OT). Dans le cas d'une automatisation complexe (par exemple SCADA ou DCS/PCS), le système de fabrication déclenche généralement le démarrage de l'ordre de travail et libère le lot après l'achèvement de l'ordre de travail.

Après le démarrage de l'exécution de l'OT, l'opérateur suit l'état de la production dans Tulip grâce à un tableau de bord qui reçoit des données en temps réel de CopaData zZenon. Cela permet à l'opérateur d'avoir en permanence une vue d'ensemble des données pertinentes du processus de production, par exemple l'état de la machine, la vitesse de la machine, l'état du lot, ainsi que la liste des alarmes critiques avec leur description et l'horodatage.

Une fois que l'équipement a terminé l'exécution de l'OT, l'opérateur examine les données de production et les alarmes et signe l'achèvement dans Tulip, en ayant également la possibilité d'ajouter des commentaires.