介绍实验室管理应用程序组中管理样品的两个选项

根据产品(如大分子、药品、血液)、实验室类型(如质量控制实验室、研发实验室、生物技术实验室)和数字化程度,不同的策略可能适用于不同的样品接收和管理。在 Tulip 的实验室管理应用程序组中,我们提供了两种主要选择:一种是基于人工的样品接收和任务分配,另一种是基于采样计划的自动接收和任务分配。本文旨在为从这两种策略中做出选择提供指导,然后详细介绍这两种策略。

:::(Info) If you'd like to learn more about the app suite, visit the Laboratory Management article

:::

我应该选择哪种方案?

两种策略("方案 A "和 "方案 B")的主要区别在于是否使用取样计划。

方案 A 采用灵活的任务分配,不使用采样计划表。收到样本后,应用程序用户手动输入样本详细信息,然后从列表中选择样本程序并分配给样本。

相比之下,方案 B 则利用采样计划表、Tulip API 连接器和自动化来简化和规范样本管理流程。要从生产批次中抽取的样品清单以及所需的样品程序都存储在取样计划表中,并通过 Tulip Automation 自动集成到实验室操作系统中。

:::(Info)Tulip API Connectors

:::

选项 A:不使用取样计划

- 灵活的任务分配:对于任何样品类型,可选择任何样品程序组合并将其分配给样品

- 可通过手动输入样品详细信息接收样品

- 与可兼容的制药业 MES 兼容(链接)

- 逐步采用:可在没有采样计划的情况下使用,之后再升级到采样计划

选项 B:使用采样计划

- 只需点击一下即可接收样品

- 管理取样计划,并在接收样品时将其用作参考数据

- 利用自动化简化用户体验

- 在实验室中使用标准操作流程

选项 A 的详细说明:灵活的任务分配

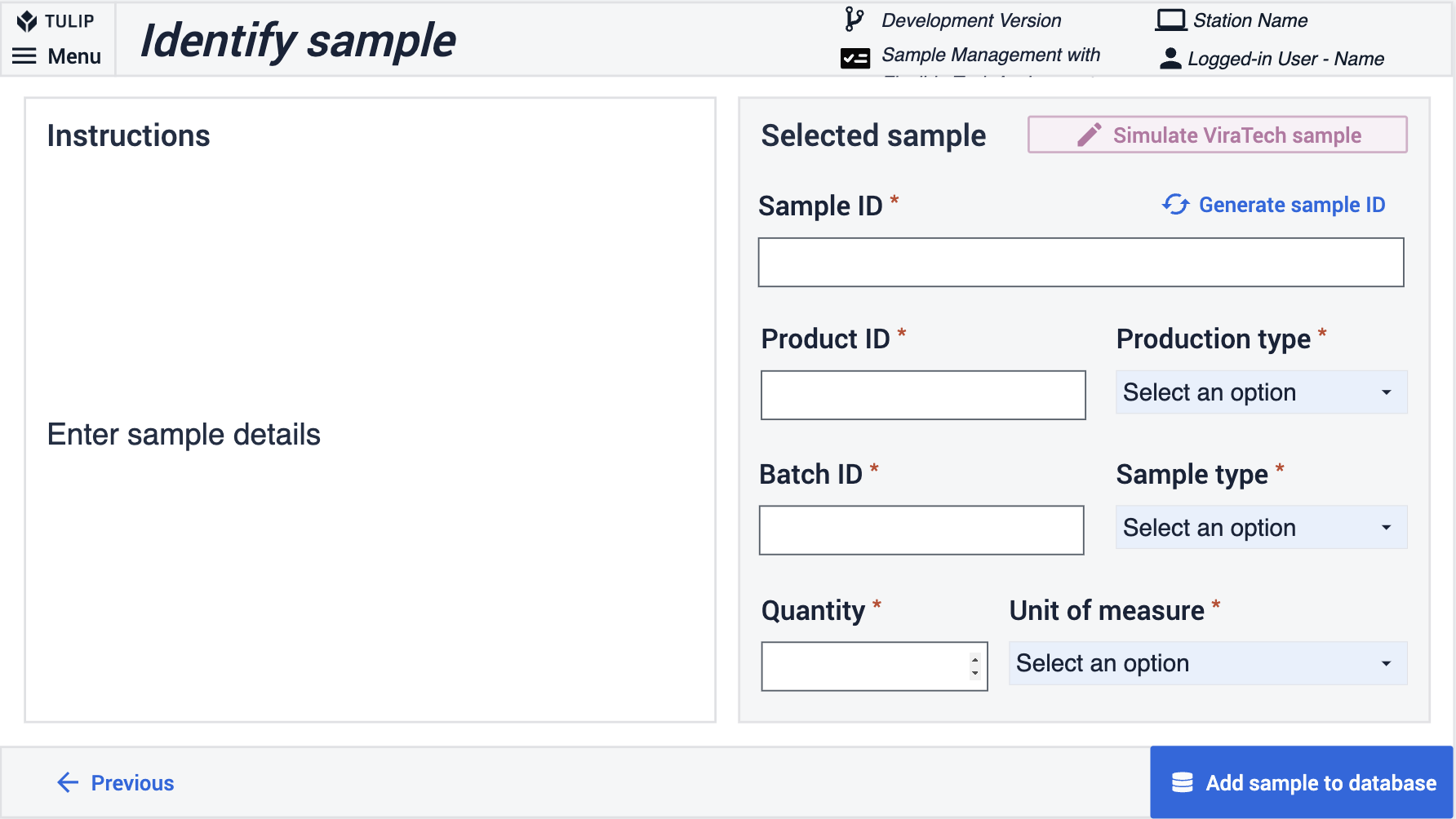

- 输入样品详细信息:作为接收样品的第一步,用户需要输入样品详细信息。这些详细信息将从样品接收文件中转移过来,并在导航时将样品添加到样品表中。如果样品是在基于郁金香的系统中采集的,因此已经在样品表中,则可以跳过这一步。

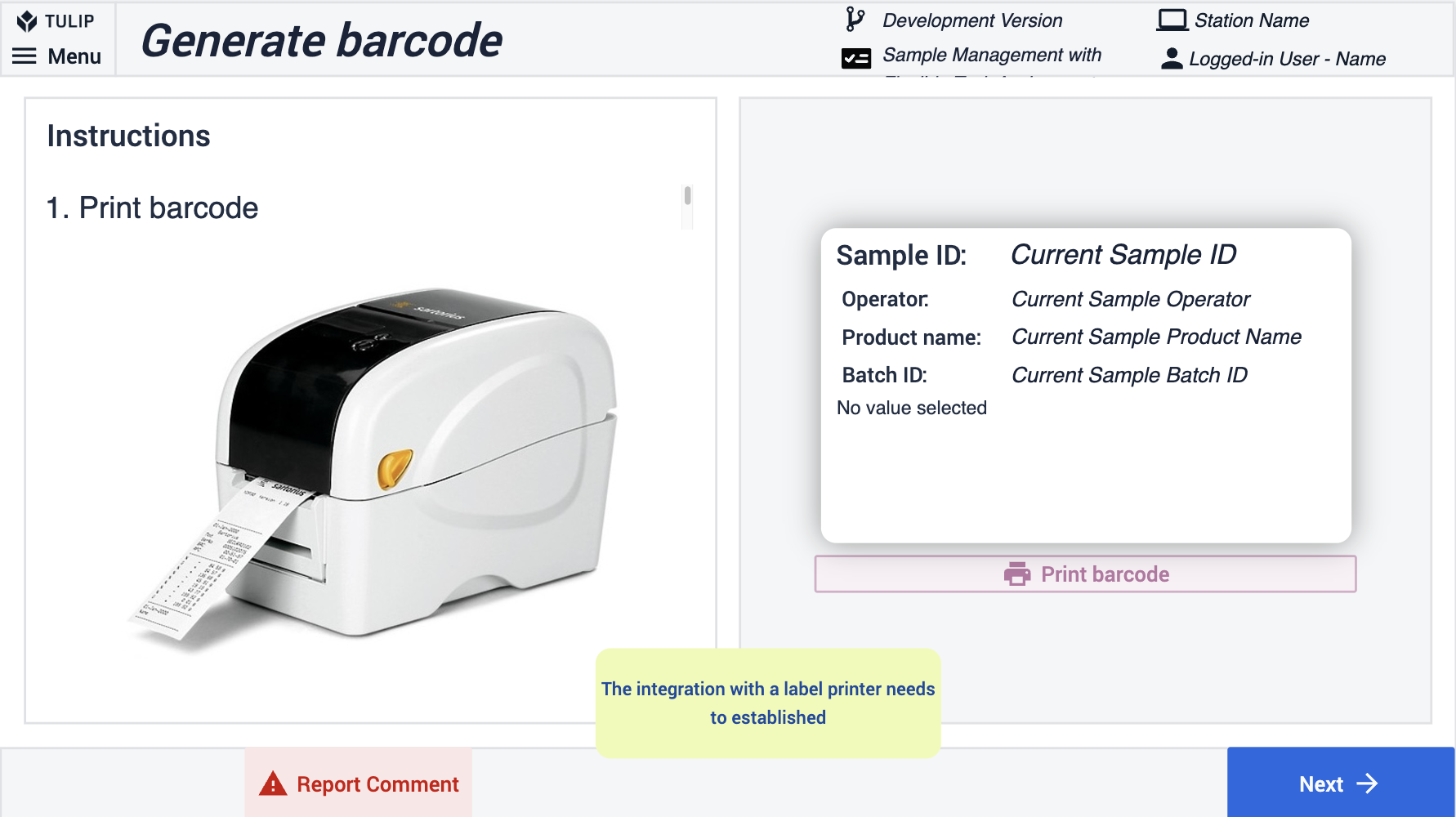

- 当样本被添加到样本数据库时,还需要在物理空间中对其进行识别。每个样本都会打印一个条形码,以便在样本生命周期内的任何时候(如将样本放入/取出仓库、执行样本程序)用条形码扫描仪识别样本。在配置该步骤时,需要将条形码扫描仪集成到该步骤中。如果样本是在基于郁金香的系统中采集的,因此已经在样本表中,且样本已贴上标签,则可跳过此步骤。

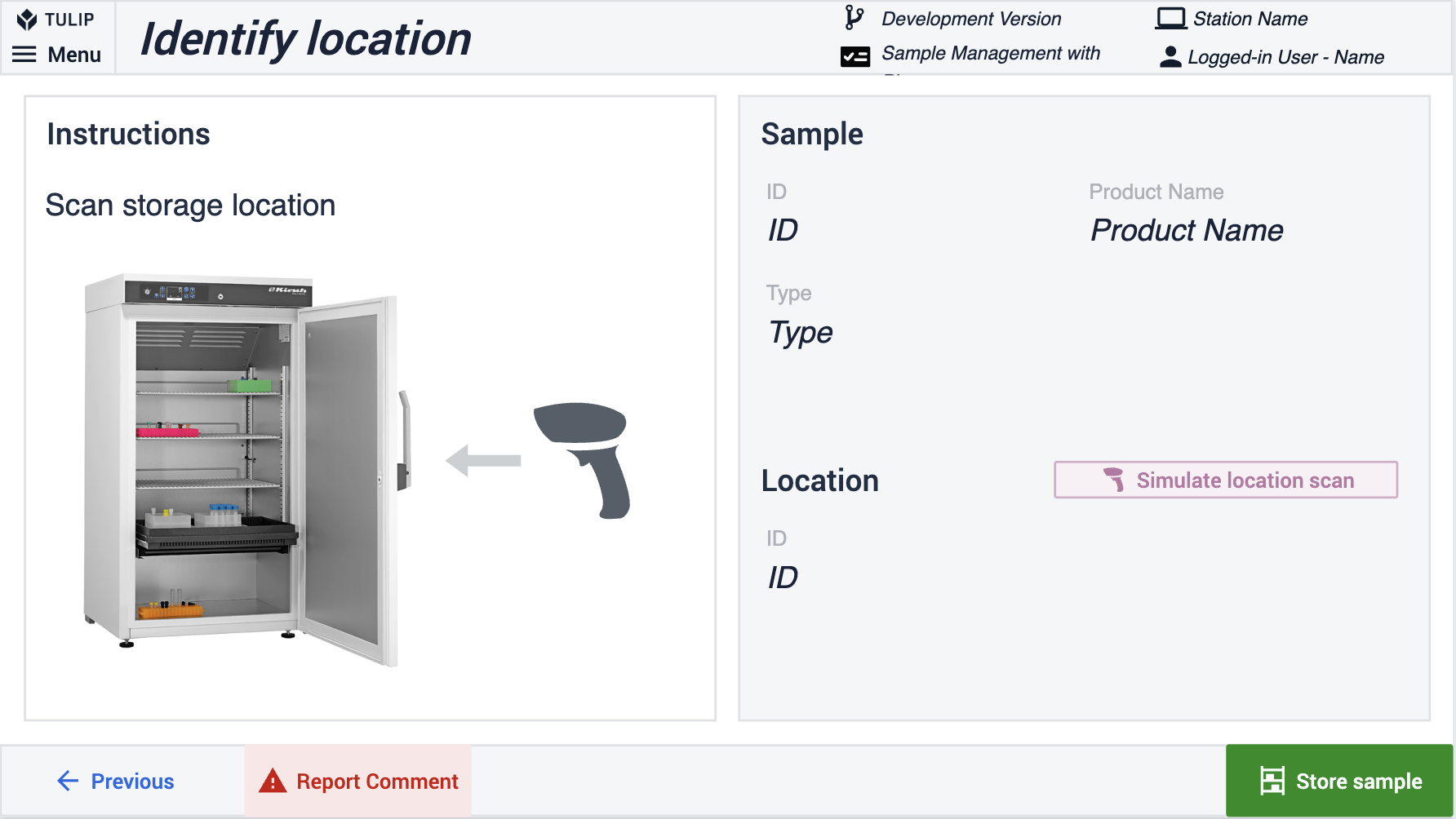

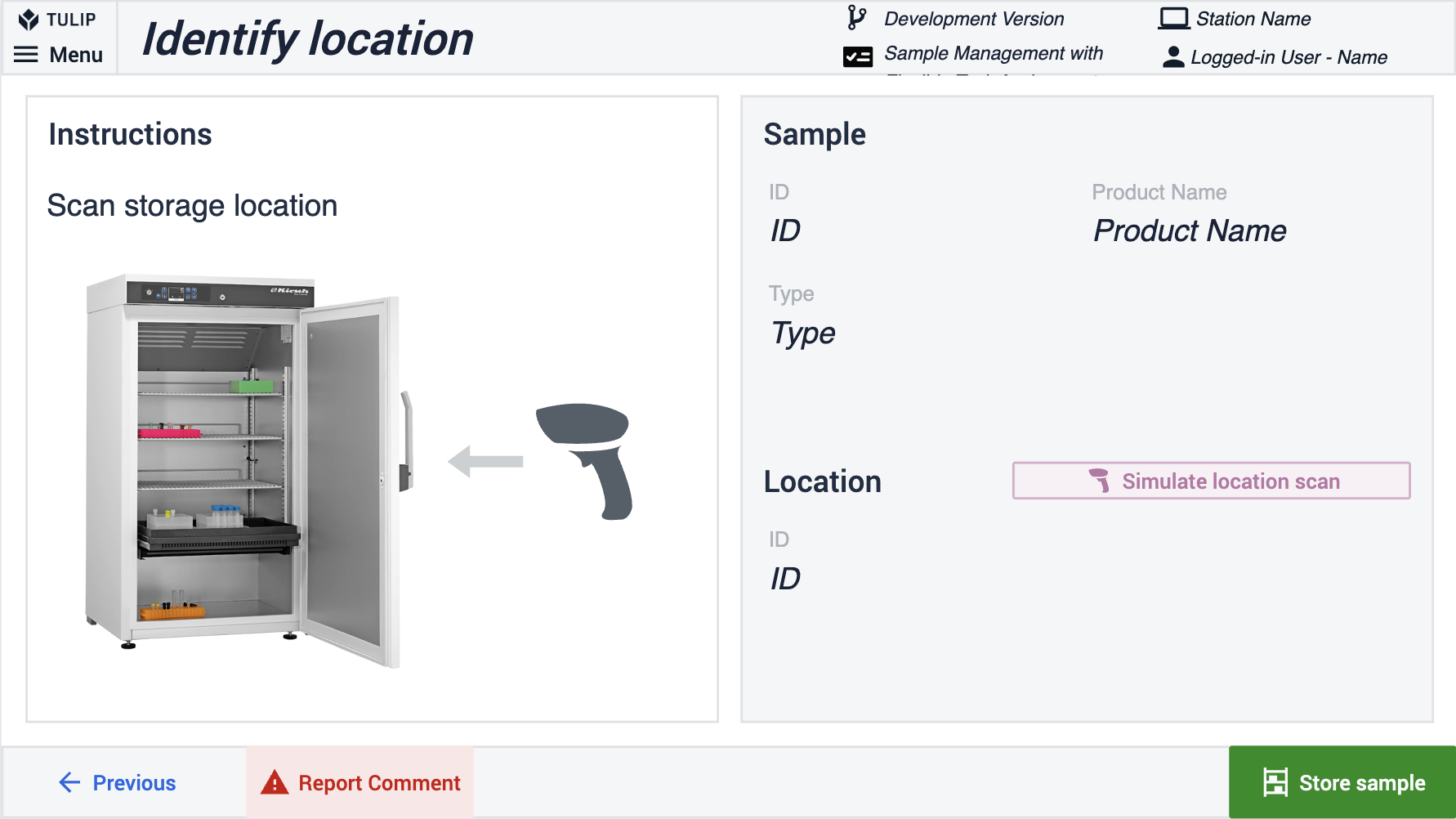

- 扫描新接收样本的存储位置,并将位置 ID 保存在样本表中

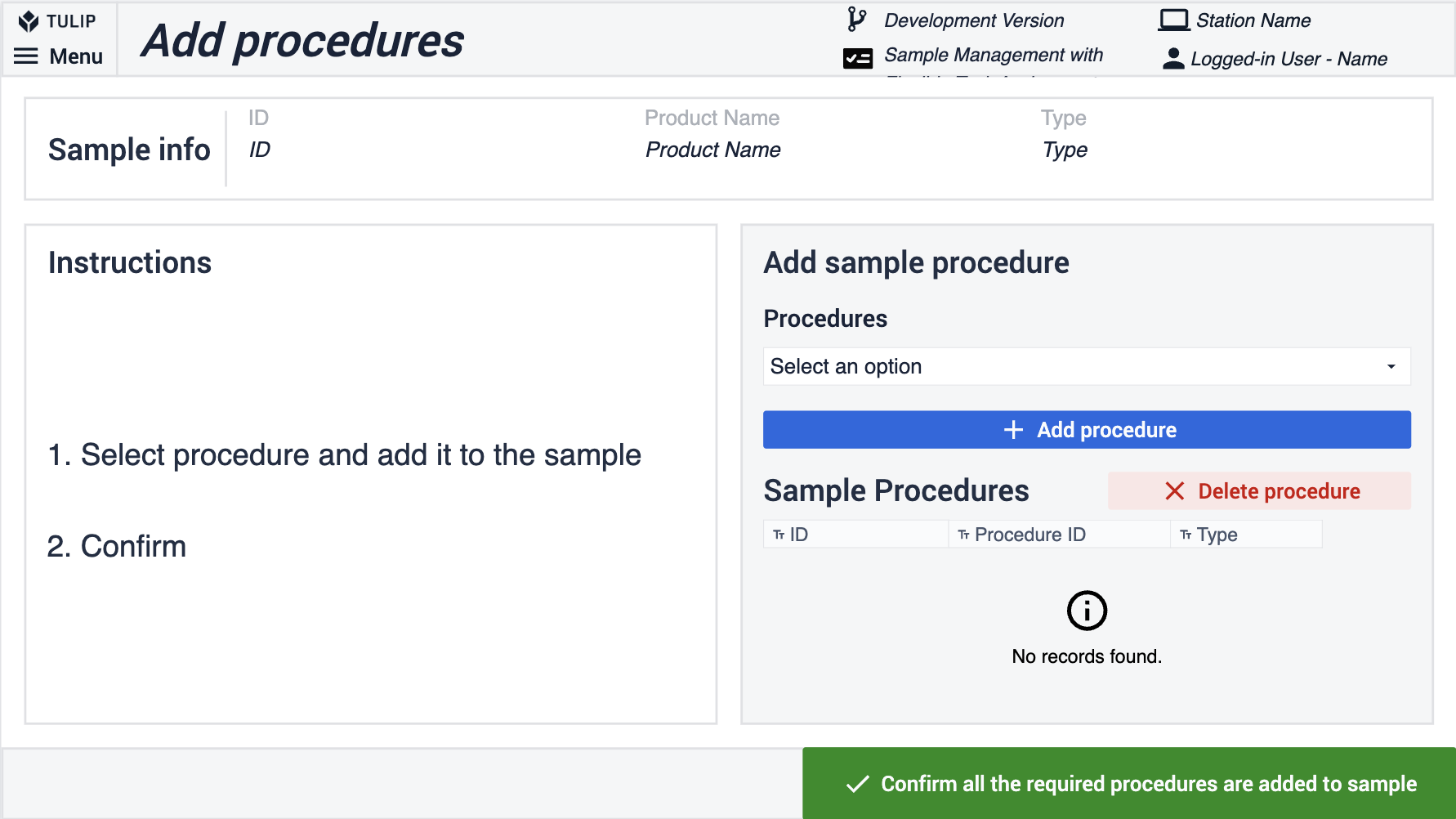

- 从单个选择 widget 中逐个选择存储过程并将其添加到样本中。添加存储过程时,会在 "任务 "表中创建一条记录,其中包含存储过程的名称和作为 "目标参考 "存储的样本 ID。添加的存储过程可在交互式表格 widget 中查看。当所有需要的程序都添加完毕后,样本接收过程就可以结束,用户可以返回主屏幕。

选项 B 的详细说明:使用抽样计划

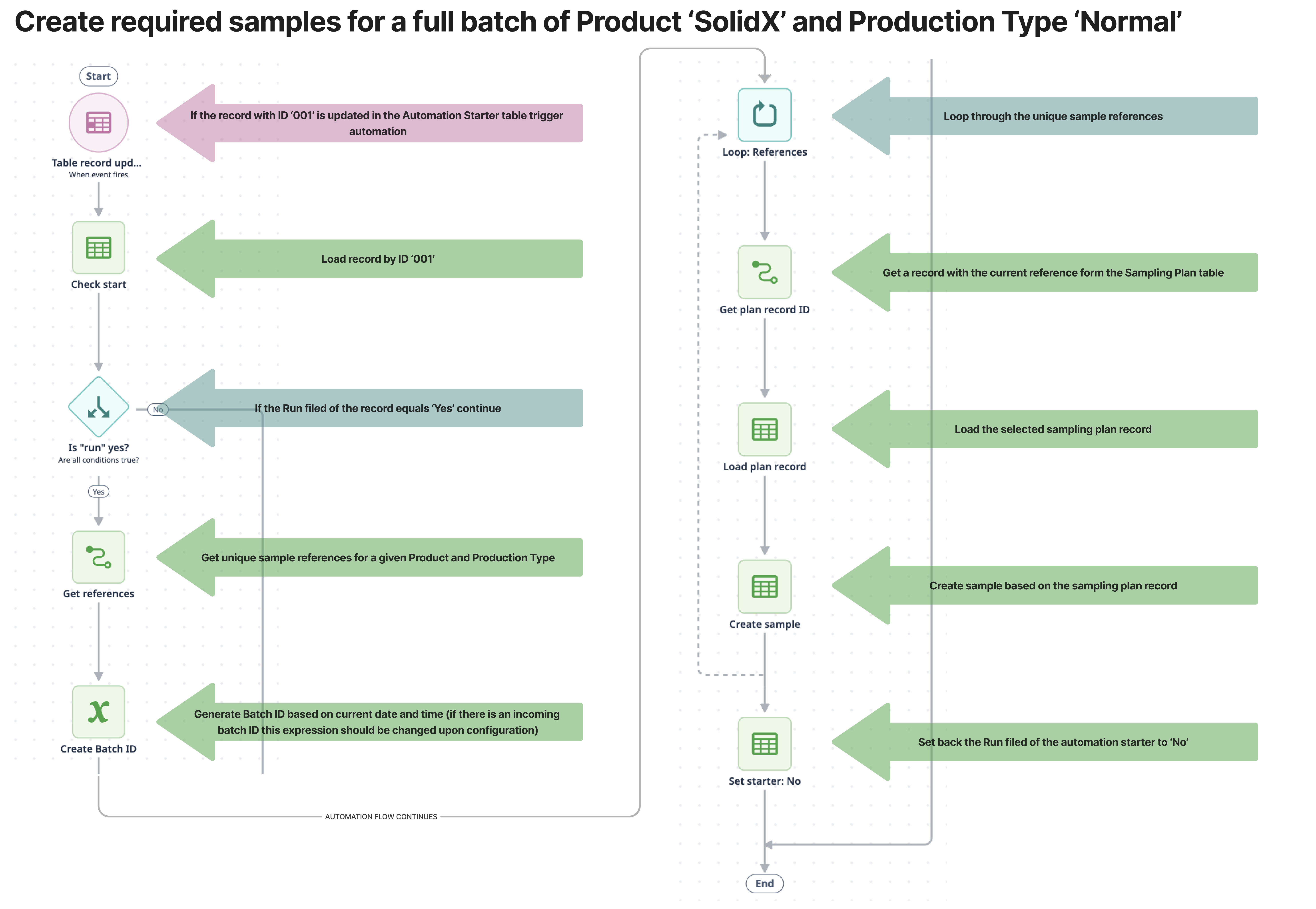

- 正在生产一批特定产品、生产类型和批次 ID 的信息必须触发第一个自动化操作:"为整批产品创建所需样品"。假设该应用程序和自动操作是从库中下载的。在这种情况下,粉红色模拟按钮将更新自动化启动器表中 ID 为 "001 "的记录,特别是将运行字段的值设置为 "是",从而触发自动化。随后,自动化将从产品 "SolidX "和生产类型 "Normal "的取样计划中提取所有样品到样品表,并赋予它们 "必须 "状态。对于多个计划,复制自动化并将参数更改为您自己的产品名称和生产类型。有关自动化如何工作的详细信息,请参阅下面的图表 "为整批产品'SolidX'和生产类型'正常'创建所需的样品"。

为整批产品 "SolidX "和生产类型 "Normal "创建所需样品 自动化

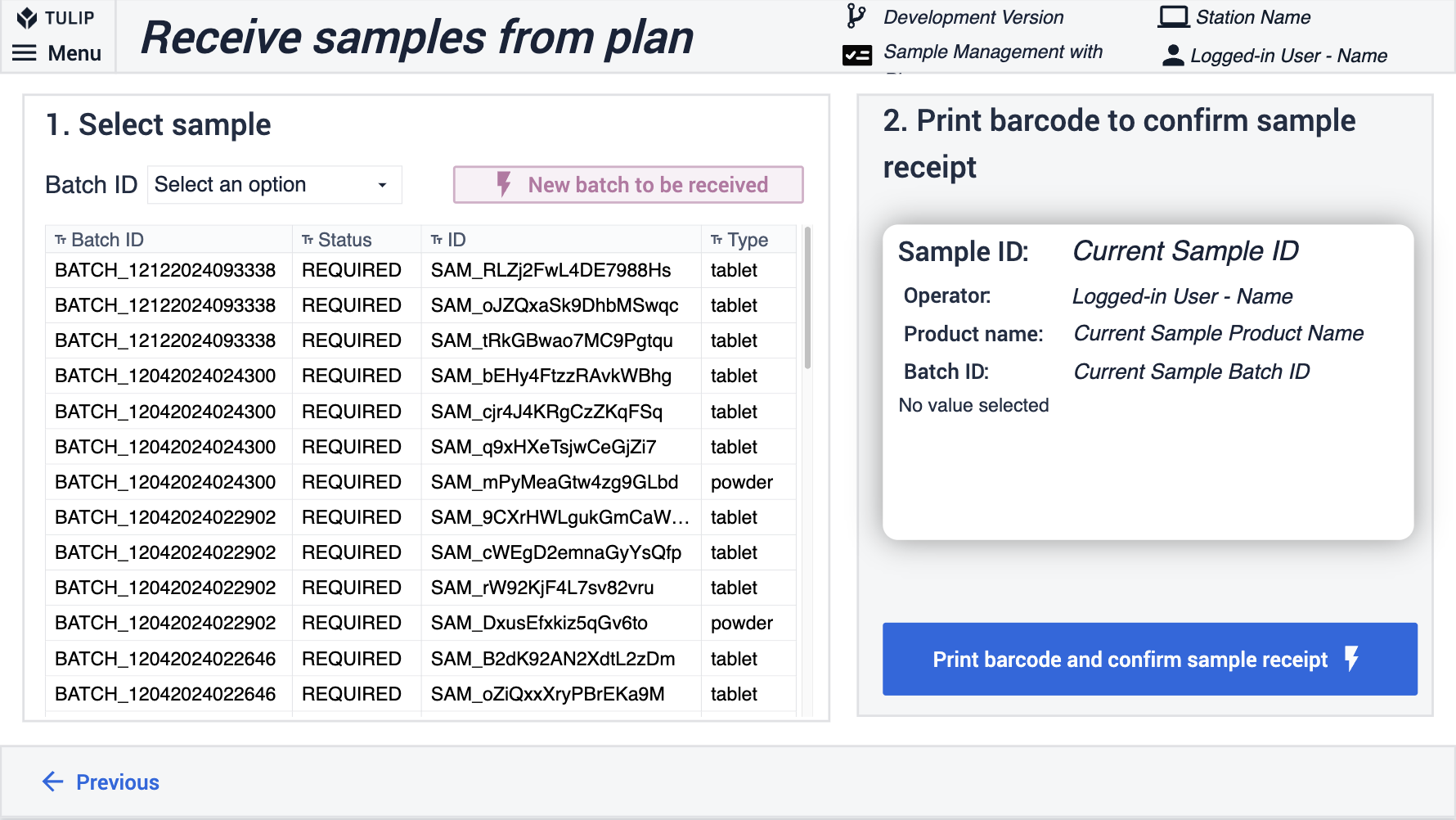

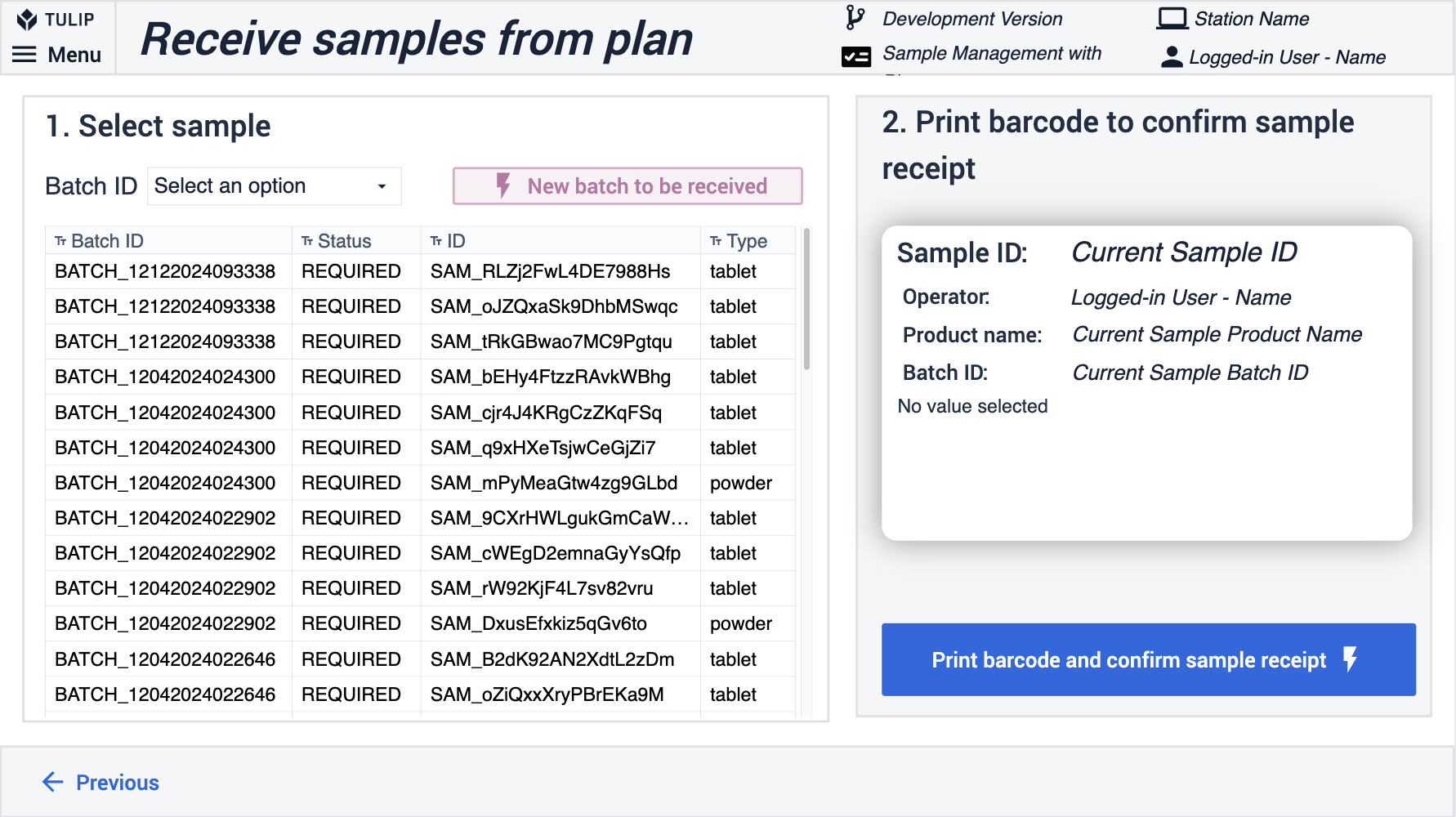

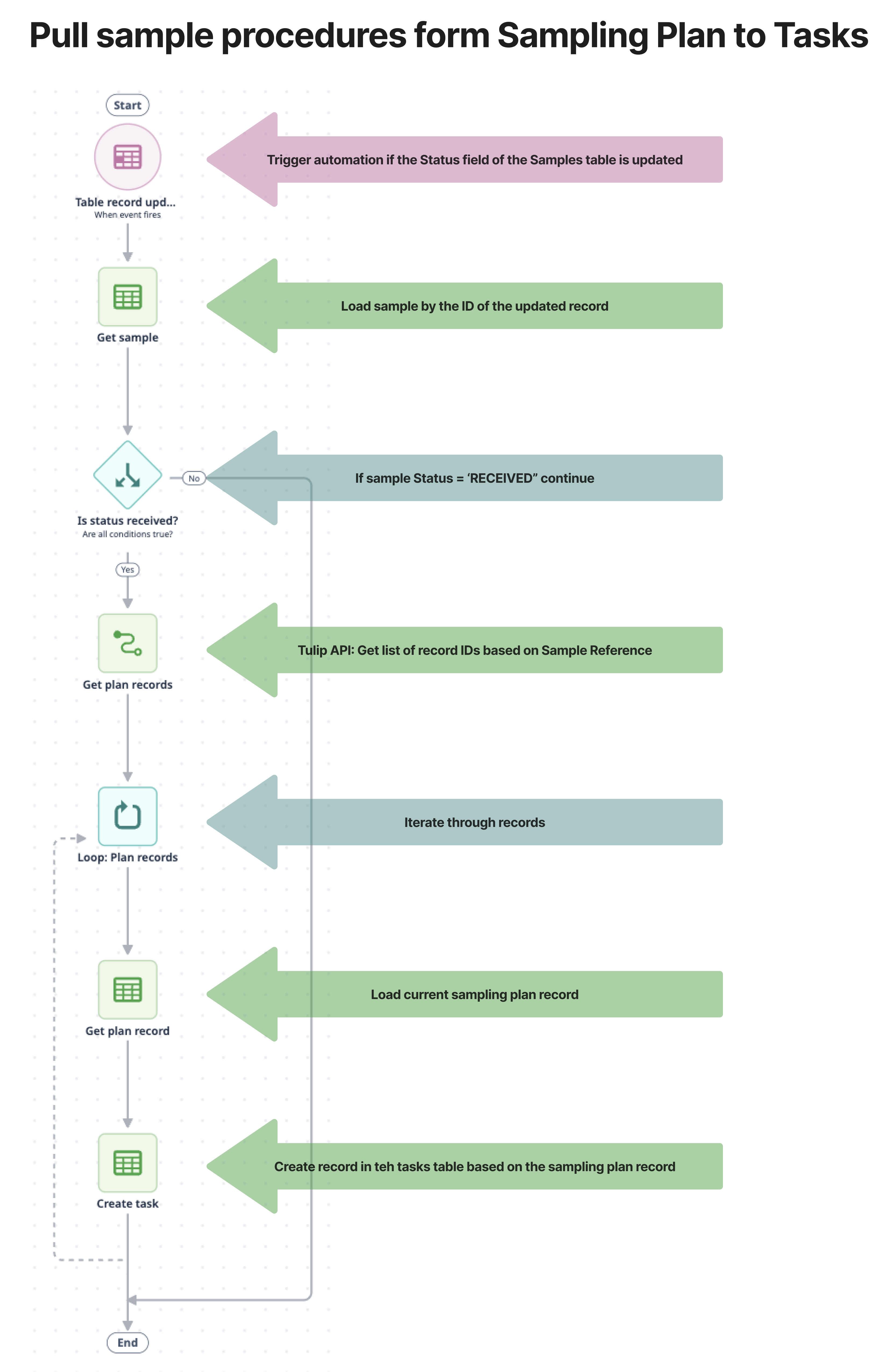

- 作为样品接收的第二步,用户需要选择所需的样品并打印标签,以便将来识别。打印标签后,样本的状态将变为 "已接收",从而触发下一步自动化操作:"从采样计划到任务中提取样本程序"。该自动操作以取样计划为参考,查找给定的样品类型,并从取样计划和任务表中的待定样品程序中提取所有需要的样品程序。有关自动化工作原理的详细信息,请参阅下图 "从取样计划到任务中拉取样本程序"。

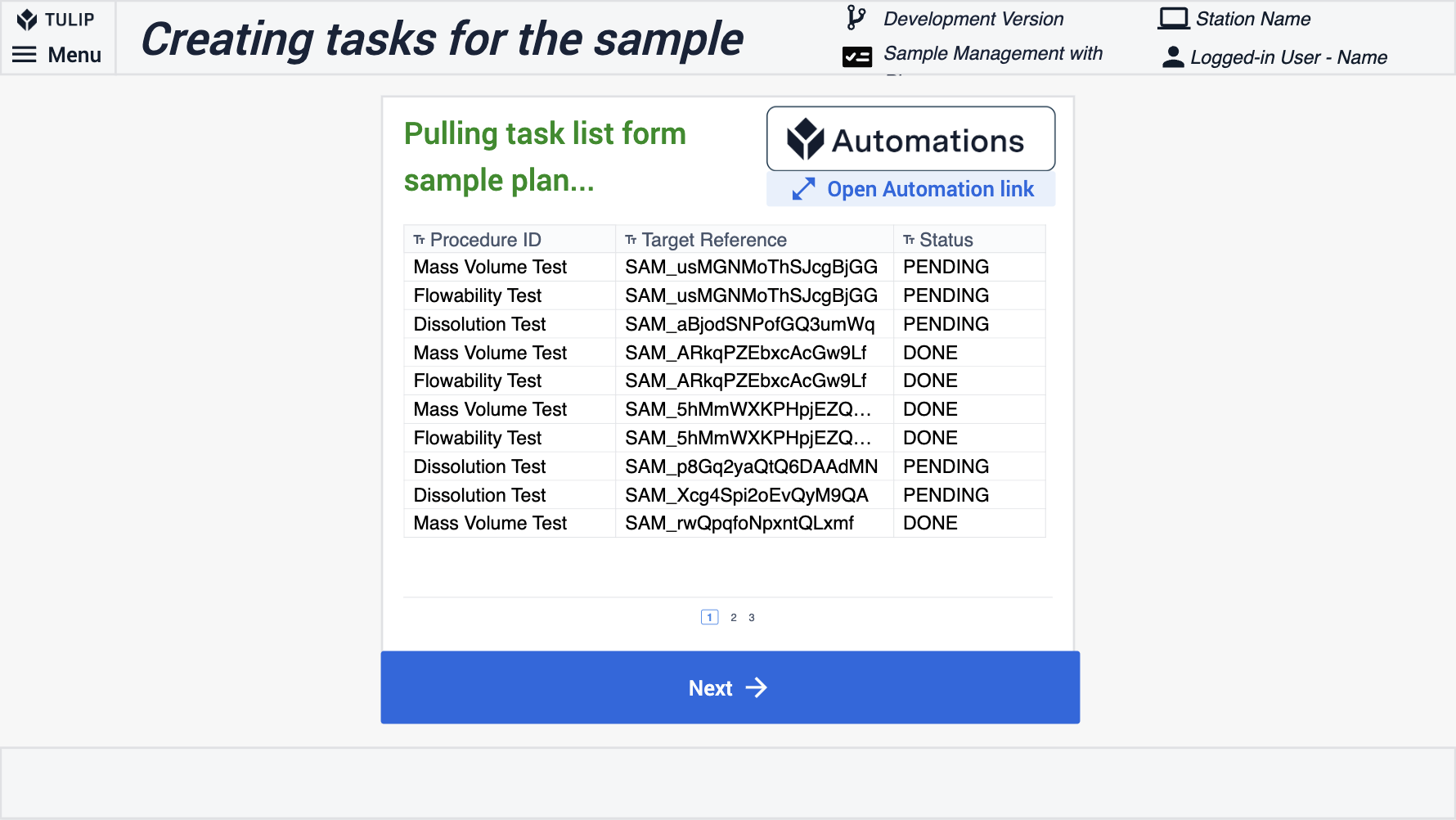

- 如果您从资料库中下载了 "使用计划进行样本管理 "应用程序和所需的自动化:"将样本程序从采样计划拉至任务 "步骤显示了如何填充任务表。如果应用程序用户不需要查看任务列表,则可以删除此步骤。

- 作为此样本接收流程的最后一步,扫描新接收样本的存储位置,并将位置 ID 保存在样本表中