To download the app, visit: Library

:::Эта статья - руководство по настройке приложения, включающее функциональное разбиение шагов и идеи по подключению к другим приложениям.

Приборная панель управления операциями является частью комбинированного набора приложений MES для управления производством от Tulip. Вы можете использовать его отдельно или в сочетании с другими приложениями.

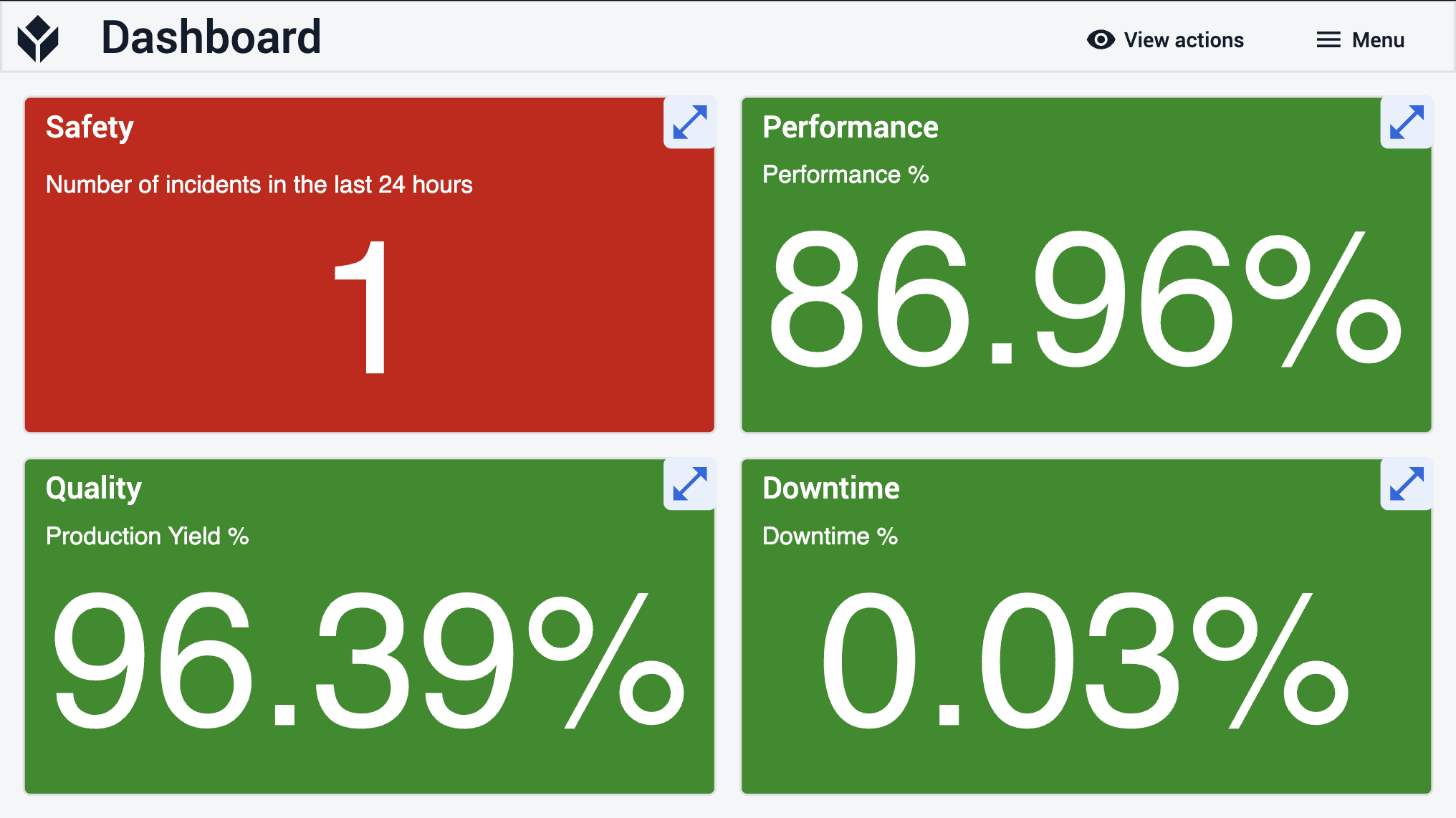

Основной этап работы приложения Operations Management Dashboard - это простая панель, на которой отображаются наиболее важные показатели безопасности, качества, производительности и времени простоя. Соответствуют ли эти показатели стандартам компании, отображается красным и зеленым цветами.

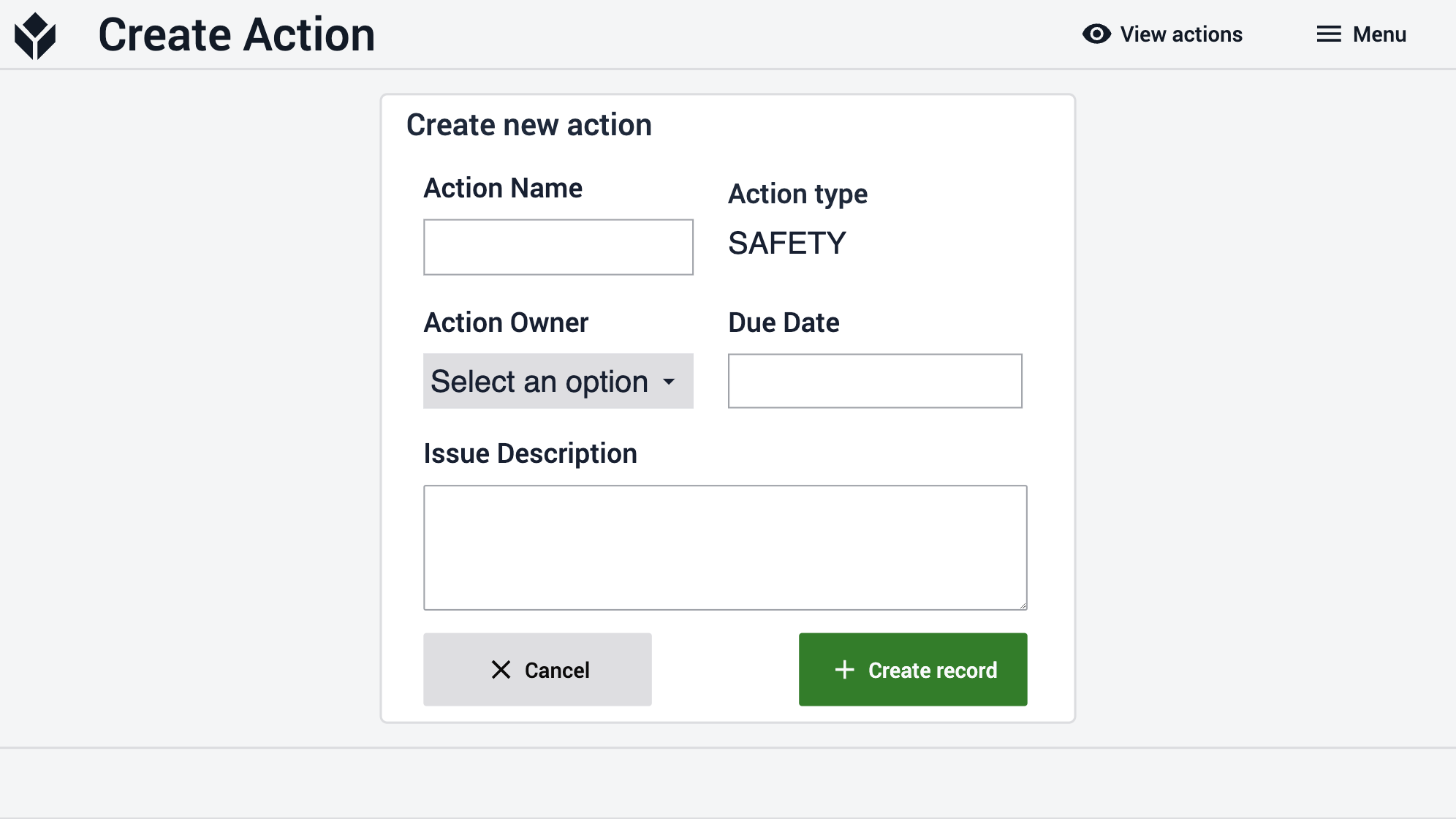

Если пользователь хочет увидеть подробную информацию о любом из четырех аспектов, он может открыть специальные шаги, содержащие множество графиков, визуализирующих данные. Кроме того, пользователи могут эскалировать проблемы, связанные с показателями, с помощью шага "Создать действие". Они также могут управлять этими созданными действиями непосредственно через приложение.

Использование и создание ценности

Приборная панель управления операциями - отличный способ начать ежедневные совещания для обсуждения показателей (безопасность, производительность, время простоя, качество).

Это может быть очень важно для понимания проблем на нескольких производственных линиях и создания четких действий на основе результатов.

Столы тюльпанов в приложении

Во всех приложениях пакета Composable MES используются общие таблицы.

Приложение Operations Management Dashboard отображает аналитику, основанную на данных, хранящихся в таблицах Tulip Tables. Две таблицы Tulip Tables, используемые в этом приложении, - это таблица "Действия" и таблица " История деятельности станции".

(Журнал) История деятельности станции

- ID: уникальный идентификатор исторической записи активности

- Идентификатор станции: идентификатор станции, связанной с исторической записью.

- Статус: Состояние станции на момент создания записи (RUNNING, DOWN, IDLE и т.д.).

- Дата/время начала

- Дата/время окончания

- Продолжительность: Продолжительность записи

- Идентификатор определения материала: Материал, произведенный в ходе деятельности.

- Целевое количество: Количество материала, которое, как ожидается, будет произведено за время действия записи (на основе целевого или запланированного времени цикла).

- Фактическое количество: Количество материала, произведенного за время действия записи.

- Дефекты: Количество бракованного материала, полученного за время действия записи.

- Причина простоя: Время простоя, зафиксированное в течение исторической записи.

- Комментарии: Поле для отслеживания примечания или комментария пользователя.

- Идентификатор заказа на работу

- Идентификатор подразделения

(Операционный артефакт) Действия

- ID: Уникальный идентификатор записи исторического действия.

- Идентификатор определения материала: Материал, произведенный в ходе деятельности.

- Название: Краткое описание, идентифицирующее характер действия.

- Место: Физическое место, к которому относится данное действие или в котором оно должно быть выполнено.

- Серьезность

- Статус: Текущий статус действия. 'Новое', 'В процессе', 'Закрыто'.

- Идентификатор рабочего заказа: Если применимо, идентификатор рабочего заказа, к которому относится действие.

- ID единицы: Если применимо, идентификатор связанной материальной единицы.

- Комментарии: Свободный текст для записи комментариев и примечаний, связанных с этим действием, дальнейшее описание действия или примечания

- Фото: Если применимо, соответствующее изображение

- Сообщено кем: Кто создал проблему, полезно для отслеживания деталей владельцем действия.

- Владелец: кто отвечает за закрытие действия.

- Тип: Категоризация действий для фильтрации или анализа.

- Принятые меры: Если действие закрыто, какие действия были предприняты.

- Дата выполнения: когда действие должно быть завершено

Конфигурация и настройка

Помощь в приложении

Как и все приложения из набора приложений Composable MES, приложение Operations Management Dashboard также содержит встроенную помощь. Это краткие описания необходимых шагов по настройке и советы по созданию приложений для дальнейшей настройки. После загрузки приложения обязательно прочитайте эти инструкции, а затем удалите их перед запуском приложения.

Таблицы, обеспечивающие ввод данных

Для работы с приложением некоторые таблицы должны быть заполнены. В частности, пользователю необходимо заполнить таблицу "История активности станции", чтобы включить аналитику. Это можно сделать с помощью другого приложения Tulip, например, приложений Order Execution, Andon Terminal, Machine Monitoring Terminal или Performance Visibility Terminal из набора приложений Composable MES. Кроме того, это можно сделать вручную в таблице Tulip или импортировав в нее CSV-файл.

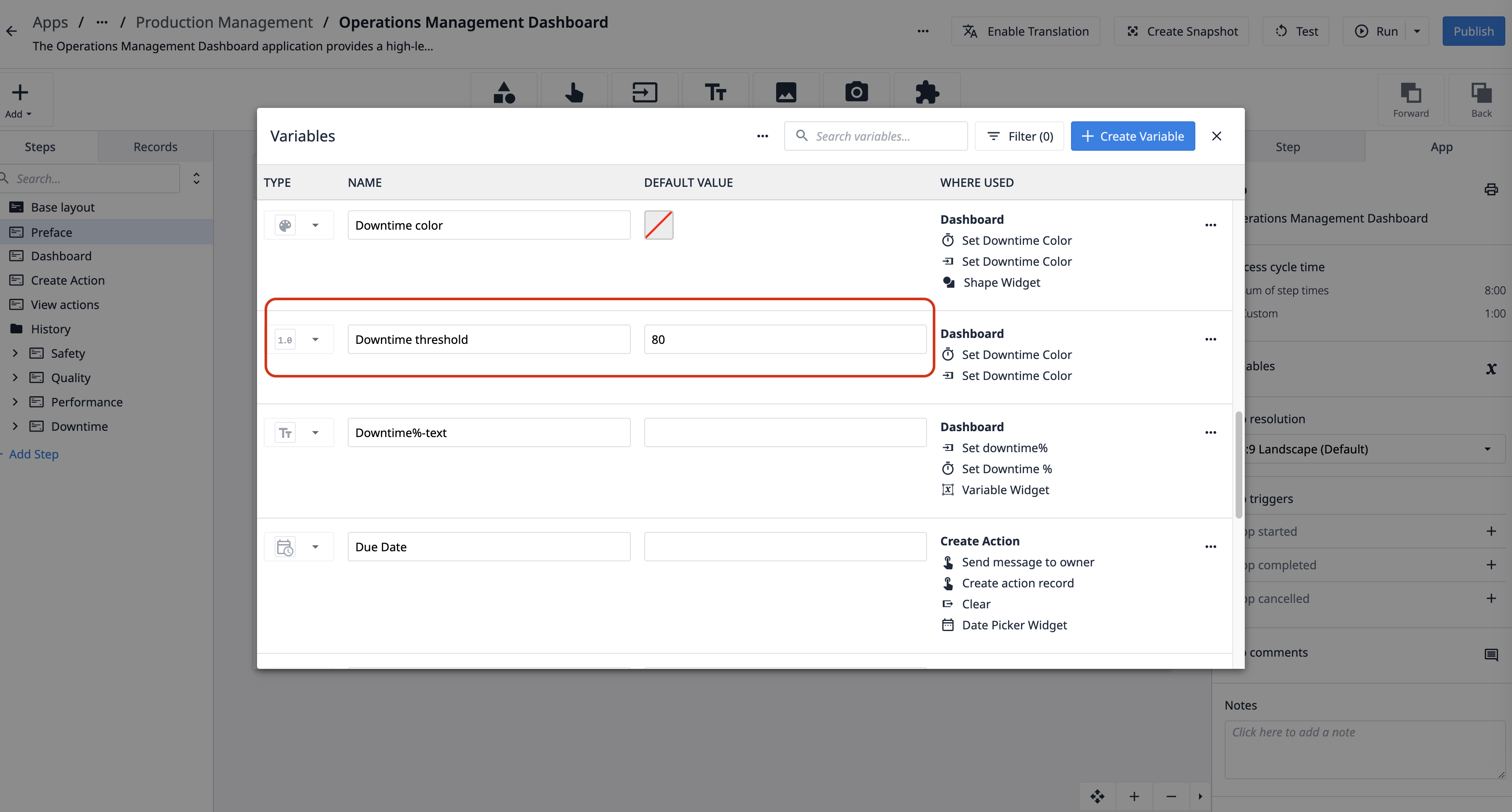

Другие потребности в конфигурации

На главном этапе работы приложения отображается приборная панель, показывающая, находятся ли основные показатели производства в пределах допустимых интервалов или нет. Эти интервалы можно настроить в соответствии с пороговыми значениями вашей операции, изменив значения назначенных переменных приложения.

Если рассчитанное значение для записей таблицы Tulip попадает в допустимый интервал, график подсвечивается зеленым цветом, в противном случае - красным. Все аналитические данные на этой панели предоставляют информацию за последние 24 часа. Пользователи могут просмотреть подробные метрики или исторические данные, нажав на кнопки с маленькими синими стрелками.

Параметры настройки

- В настоящее время переменная Action Type на шаге Create Action предопределена навигационной кнопкой Create Action. Если вы хотите изменить это и включить дополнительные типы действий, рекомендуется заменить предопределенные переменные виджетом Single Select. В этом случае также рекомендуется удалить логику триггера, сохраняющего тип действия, из кнопок Create Action.

Расширенные соединения приложений

Примеры подключения приложений для работы друг с другом

Выполнение заказов

Приложение Order Execution регистрирует активность станции в таблице Station Activity History Table. Приборная панель управления операциями использует этот журнал в аналитике.

Andon Terminal

Приложение Andon Terminal регистрирует активность станций в таблице истории активности станций. Приборная панель управления операциями использует этот журнал в аналитике.

Терминал видимости производительности

Приложение Performance Visibility Terminal регистрирует активность станции в таблице истории активности станции. Operations Management Dashboard использует этот журнал в аналитике.

Терминал машинного мониторинга

Приложение Machine Monitoring Terminal регистрирует активность станции в таблице Station Activity History Table. Панель управления операциями использует этот журнал в аналитике.