Imagine you’re a production manager in a regulated industry that needs to provide thorough genealogy records for traceability purposes. Operators spend time manually writing process data which comes with high possibility of errors, such as incorrect measurements, poor handwriting, or forgotten fields. These mistakes lead to compliance issues that can be damaging for the entire organization. You introduce a digital solution of process apps that captures data in standardized formats, eliminating common disparities. In a separate traceability app, you can sort and filter through data to find trends that drive process improvements. This solution saves time, avoids error-prone manual entry, and creates clear, traceable data for customers and quality assurance.

Genealogy and traceability allow for a manufacturing facility to see as-built-configuration context. For discrete manufacturing, this may include the part numbers, serial numbers, lot numbers of unserialized parts and raw materials that composed subassemblies and final assemblies. This use case involves taking all the data captured during a build process and storing it for review along with metadata (who did what, when, any confirmation checks).

The two main goals of this use case are:

-

Capture industry-compliant genealogy records available to your end-customer and/or auditor

Because compliance is regulatory in manufacturing, this is an essential piece of your operations. You can compile a complete audit trail with a digital solution that minimizes effort while meeting necessary standards. -

Enable traceability forwards or backwards

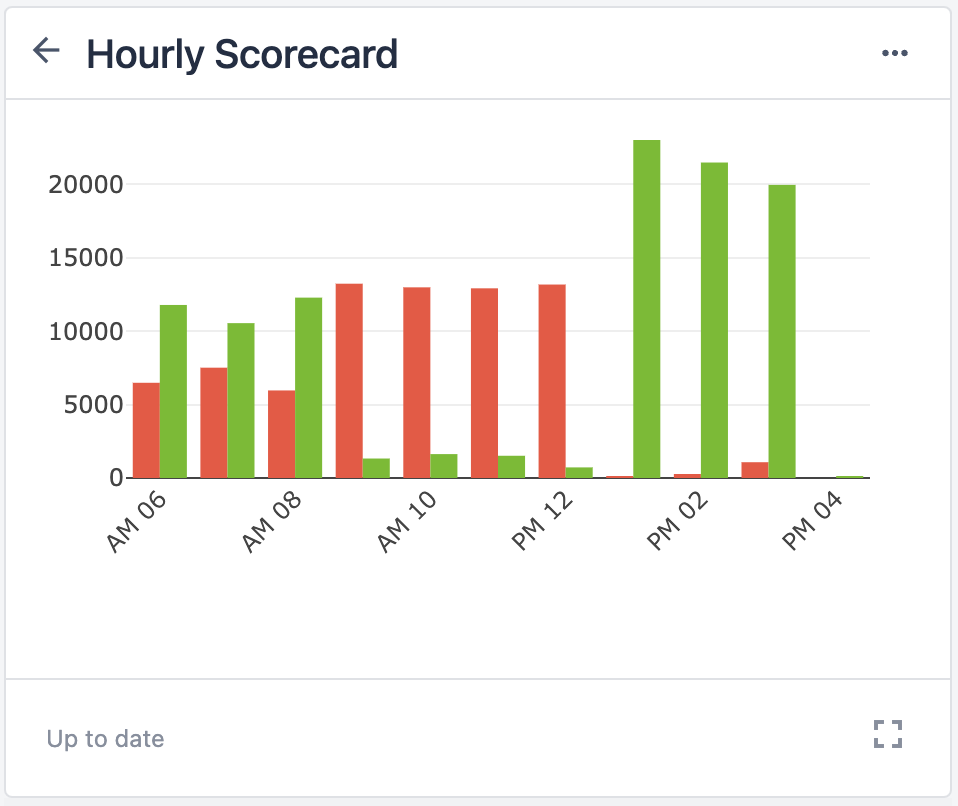

Digital traceability of a product from production to shipping creates accountability. The chart below demonstrates how digital traceability can benefit different scenarios throughout production:

| Scenario | Digital traceability benefit |

|---|---|

| Standard work: Product moves through material lots and subassemblies | App metadata (completions) automatically stores data including operator info, datetimes, any value selections |

| Rework: a product or component requires additional attention before it can be used in assembly | Immutable data provides the full history of a part on one step for easy reference |

| A customer requests records of a specific product | Retrieve all relevant product data that’s stored digitally using an app |

| Warranty recall or lot issue identified by vendor | Quality personnel can search and pull a list of products that used the relevant faulted part |

Impacts and Requirements

Digital and traditional genealogy methods produce the same result, but a digital solution offers easier and more automatic traceability. If you’re currently using production tracking apps in your process, then you’re already capturing important data for genealogy. A digital solution gathers relevant data for each lot and then displays the data when needed to provide a complete history.

The main goals of genealogy address compliance with following methods:

- Lower the cost of compliance

Handle and analyze data, and limit human errors through automated data collection - Simplify the process to create traceability

Make data ready and available to those who need it through digital storage - Open up process improvements

Use data trends to identify issues when they arise and key areas to improve as a result

Data availability is a key factor to achieve these goals. You can search, filter, and share information with ease and less errors than with a standard paper process. Different personas require data in different contexts, such as quality review or identifying trends in operations.

As an additional benefit, compliance also leads to increased product quality. This includes rapid identification and rework of work-in-progress goods affected by a quality excursion. Product quality can accomplish the following:

- Improved customer satisfaction

Meet customer’s expectations, build repeat business, and establish a good reputation in customer markets - Higher profitability

Increase ROI and overall revenue while also decreasing service costs from defects - Reduced risk

Avoid setbacks and potential fines that can result from defective products

Genealogy is relevant to all industries and required for regulated ones. This use case has a low/medium complexity, depending on your specific operation. For example, multi-level batch processing requires additional configuration, while simple, discrete assembly has a 1:1 relationship with apps, making it easier to gather the data. Minimum set up involves basic app building and data collection with tables and completion records.

How to Get Started

There are two main components of digital genealogy:

- Collecting the data

- Viewing the data in one place

Let’s go through both to understand what they look like for this use case.

Collect Data

Use a mix of Tables and Completions to store product and process data.

Tables

Because genealogy comprises data collected during multiple processes, you need to establish a scalable table structure. A scalable table structure:

- Follows the digital twin model (tables that mirror physical locations/shop floor)

- Has tables that represent either physical (ex: inventory items, equipment & assets) or operational artifacts (ex: defect event, work orders)

- Does NOT store master data (data created outside of operations) or duplicate data from completion records (application metadata)

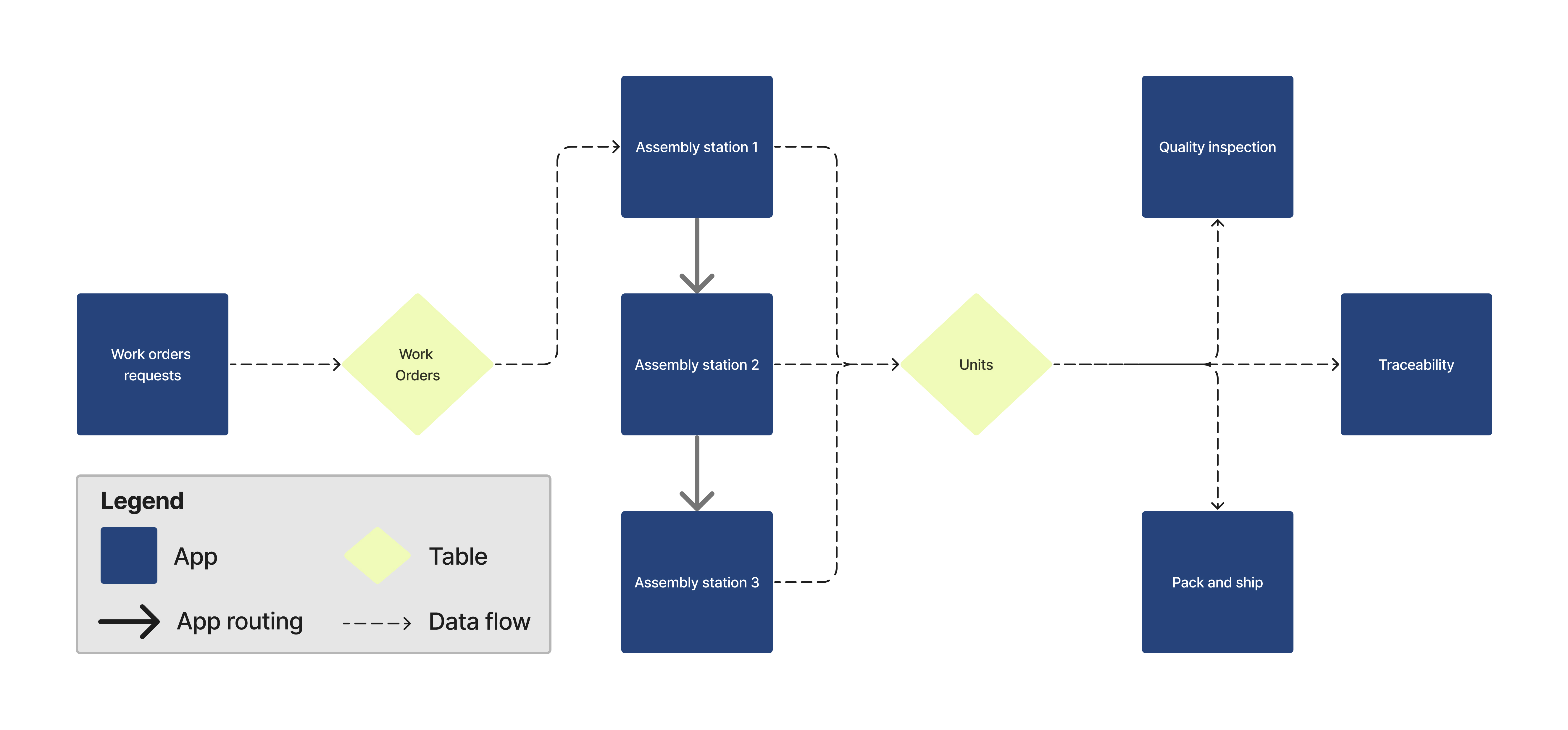

In app architecture, a table structure is what connects each app to one another. In the diagram below, you’ll notice how the apps (blue squares) aren’t all directly connected. The tables (green diamonds) move work order information through production.

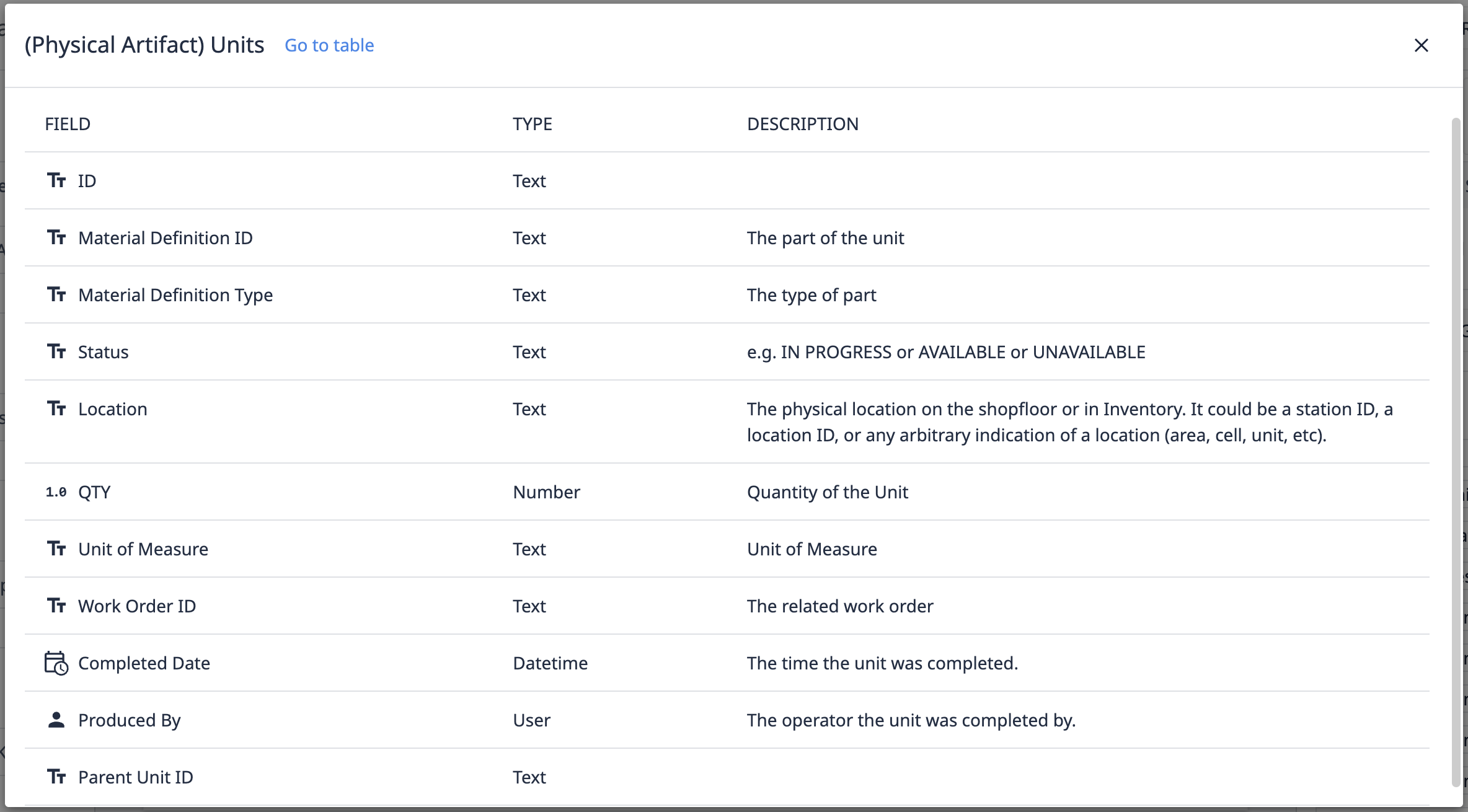

In this diagram, work order requests store in a Work Orders table. The first assembly station uses the work order information to begin. Each station stores the data pertaining to the Unit in the Units table. The Units table (example below) has information about each unit. These records can then be used in a traceability app, or other apps such as quality inspection and pack and ship.

This architecture ensures that data is accurate across Stations and doesn’t live in multiple locations. Because the data collected for genealogy comes from various process apps, make sure that Triggers write to and update Table Records in the appropriate tables.

Your table structure does not need to be extensive. You can use or refer to the Tulip Common Data Model as a starting point and tailor it to your specific needs.

Completions

Completions store immutable app metadata, but you can also configure triggers to save Variable values. This information informs what happened during an app’s session. For genealogy, completion records capture information about the production conditions.

Note that completion records are specific to each app, like a log. While you can’t use the information in other apps, you can visualize completion data using Analytics.

View genealogy data in one place

After collecting data from different processes into tables, you’ll likely want to view information for a unit in a separate application. A genealogy app should be simple so users can easily access data.

In the example app below, a user can select a unit from an interactive table widget.

The app then goes to the next step, which displays data of the selected unit in a table record widget.

This a basic app design for retrieving information on specific units. You can tailor a genealogy app to different personas depending on conditions they need to search records for.

The table below provides examples of additional app features you may consider:

| Scenario | App feature |

|---|---|

| A quality manager notices a reoccurring issue with a produced part | Create a table filter for units that were produced during a specified datetime period |

| A vendor issues a recall on one of the materials used in production | Create a table query that retrieves records that include the relevant material ID |

| A customer asks to see full unit history | Export a CSV file from the interactive table widget of unit history |

Tulip Resources

Whether you want to learn more about Tulip features to build a genealogy/traceability app or you want to use Tulip’s ready-made templates, we have the tools to help you get started.

.gif)