La suite de aplicaciones Laboratory Operations agiliza los flujos de trabajo esenciales de laboratorio para entornos como el control de calidad farmacéutico y los laboratorios de grandes moléculas. Permite un seguimiento eficaz de las muestras, el control del inventario y la supervisión operativa, lo que permite a los laboratorios mantener la conformidad y mejorar la productividad. Este conjunto de aplicaciones se integra perfectamente con el ecosistema más amplio de Laboratory Operations, incluidos los conjuntos de aplicaciones Instrument Management y Sample Procedure.

Tablas utilizadas en el grupo de aplicaciones

Las principales tablas Tulip Tables que utiliza el grupo de aplicaciones son las tablas Samples, Tasks y Inspection Results. Todas las muestras pueden almacenarse en la tabla Samples con diferentes estados (REQUIRED, RECEIVED, PROCEDURE DEFINED, PROCEDURE COMPLETED, APPROVED, REJECTED, DISPOSED), y los procedimientos de muestra pueden vincularse a ellas en la tabla Tasks. A continuación, la tabla Resultados de inspección se utiliza para almacenar los resultados de las inspecciones de muestreo. Además, en el cuadro de mandos aparecen las tablas Comentarios y Excepciones, así como la tabla Instrumentos. Sin embargo, estas tablas no siempre se rellenan en las aplicaciones de gestión, sino más bien en otras aplicaciones de proceso.La tabla Materiales se utiliza para almacenar los artículos del Inventario y sus cantidades y ubicaciones.El uso de la tabla Plan de muestreo es opcional. Si los usuarios desean almacenar una lista de muestras que deben tomarse de un lote y los procedimientos de muestreo que deben ejecutarse en estas muestras, Tulip ofrece una solución dinámica. La tabla Sampling Plan puede almacenar toda esta información, y Tulip Automation puede utilizarse para extraer datos de la tabla al sistema de gestión de muestras.

:::(Info)If you'd like to learn more about Tulip's Common Data Model (CDM)

for Pharma, check out this link.

:::

El grupo de aplicaciones de Gestión de Laboratorio incluye las siguientes aplicaciones:

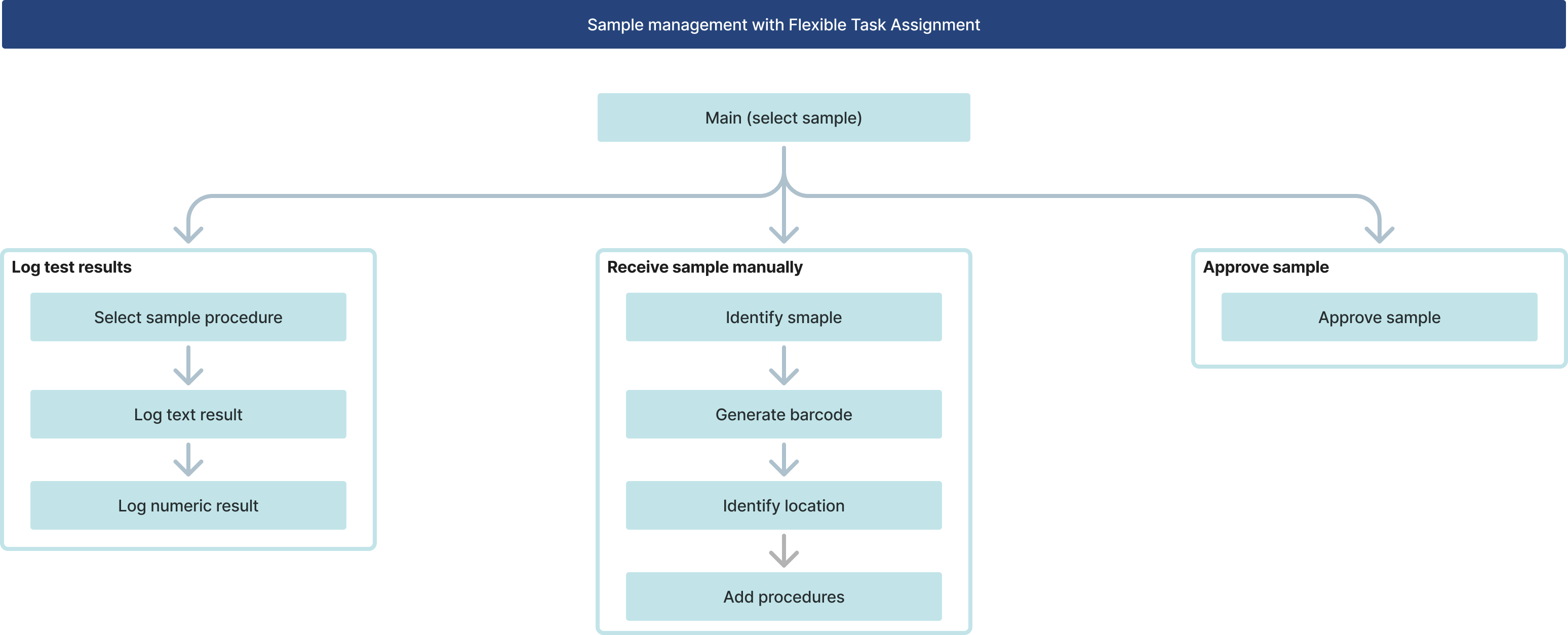

Gestión de muestras con asignación flexible de tareas

La aplicación de gestión de muestras proporciona un flujo de trabajo optimizado para la recepción, el registro y la aprobación de muestras. Permite a los usuarios identificar y codificar con barras las muestras, vincular procedimientos, registrar resultados y aprobar muestras de forma eficaz, garantizando un seguimiento y una gestión exhaustivos de las muestras. La opción de registro de resultados puede utilizarse en los primeros pasos de la adopción, cuando aún no se han digitalizado todos los procedimientos normalizados de trabajo de las muestras. De este modo, se puede utilizar una única interfaz para registrar los resultados de los distintos tipos de inspecciones. En fases posteriores de la adopción, las aplicaciones de procedimientos de muestreo pueden ofrecer opciones para seguir instrucciones de trabajo digitales y registrar los resultados de las inspecciones de forma guiada.

:::(Info) Options for sample management article

:::

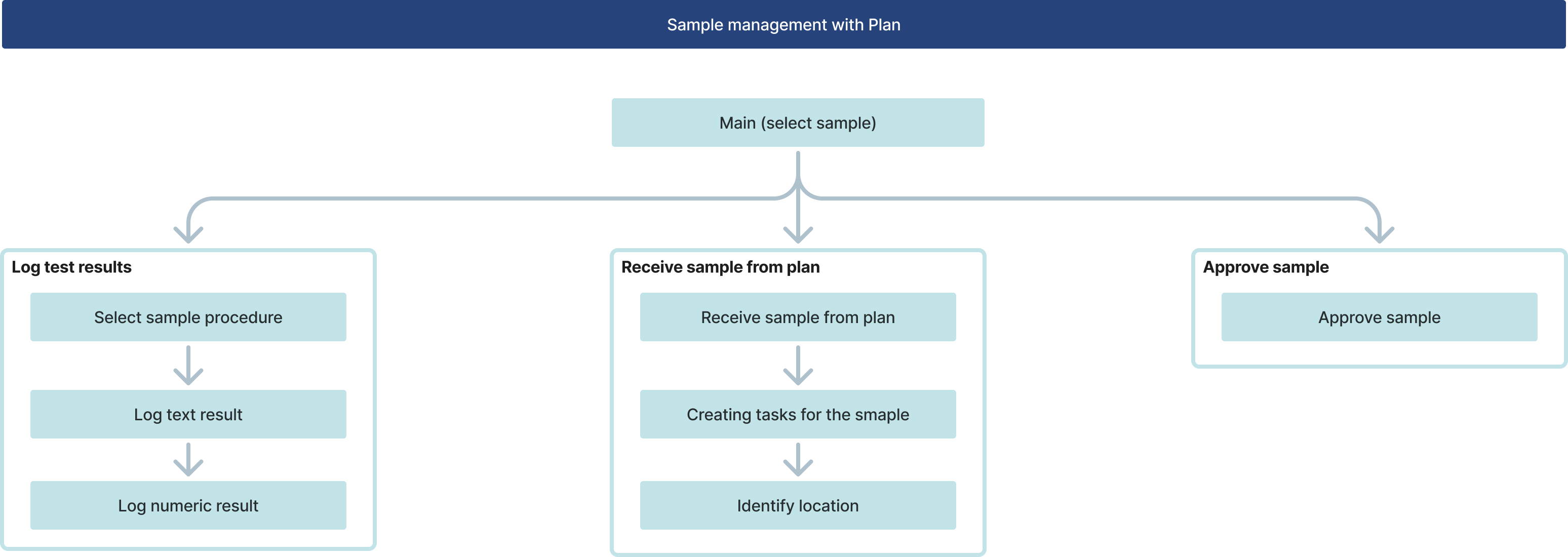

Gestión de muestras con planos

Esta aplicación es similar a la aplicación de Gestión de Muestras sin planos en su propósito: proporciona un flujo de trabajo racionalizado para recibir, registrar y aprobar muestras. Los grupos de pasos de aprobación de muestras y registro de resultados son idénticos en las dos aplicaciones. La principal diferencia es que esta aplicación utiliza un plan de muestreo basado en Tulip Table para la recepción de muestras. En primer lugar, la aplicación recibe una lista de las muestras que se esperan de la producción de un lote específico. En este punto, el estado de estas muestras es "REQUERIDO" y puede cambiarse a "RECIBIDO" tras la recepción de la muestra. Se puede utilizar la automatización para rellenar la tabla Tareas con los procedimientos de muestreo de la muestra recibida en función del plan de muestreo.

:::(Info) Options for sample management article

:::

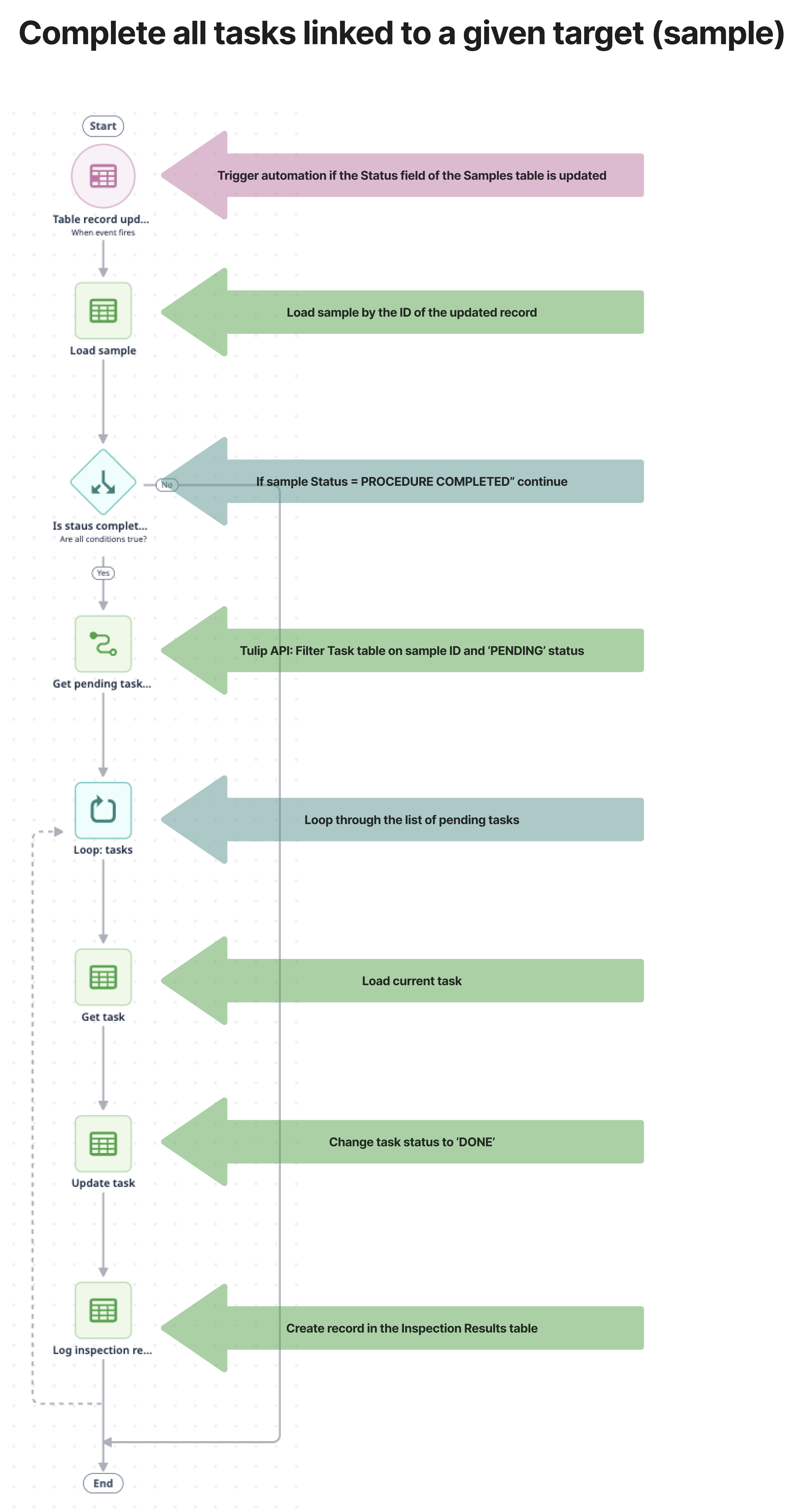

En el paso 'Aprobar muestra' el botón completar todo activa una automatización 'Completar todas las tareas vinculadas a una muestra objetivo dada'. Para probar esta funcionalidad es necesario descargar la automatización de la biblioteca de Tulip. Para obtener más información sobre el funcionamiento de la automatización, consulte el diagrama "Completar todas las tareas vinculadas a un objetivo determinado" que aparece a continuación:

Completar todas las tareas vinculadas a un objetivo determinado muestra Automatización

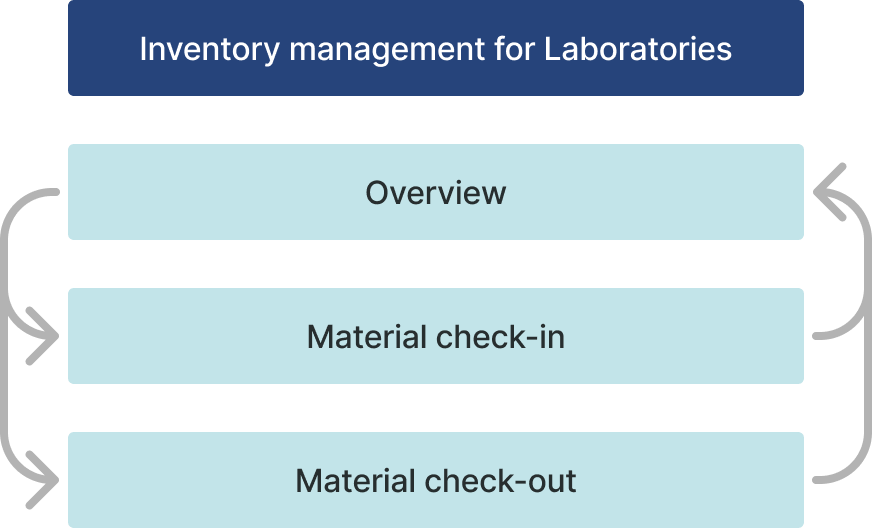

Gestión de inventarios para laboratorios

Colocar materiales en zonas de almacenamiento, como cámaras frigoríficas o estanterías de inventario, y registrar cuándo se retiran es esencial para una gestión eficaz del laboratorio. Esta aplicación permite a los usuarios escanear los materiales durante la entrada y la salida, lo que posibilita el seguimiento en tiempo real de la ubicación de los materiales.

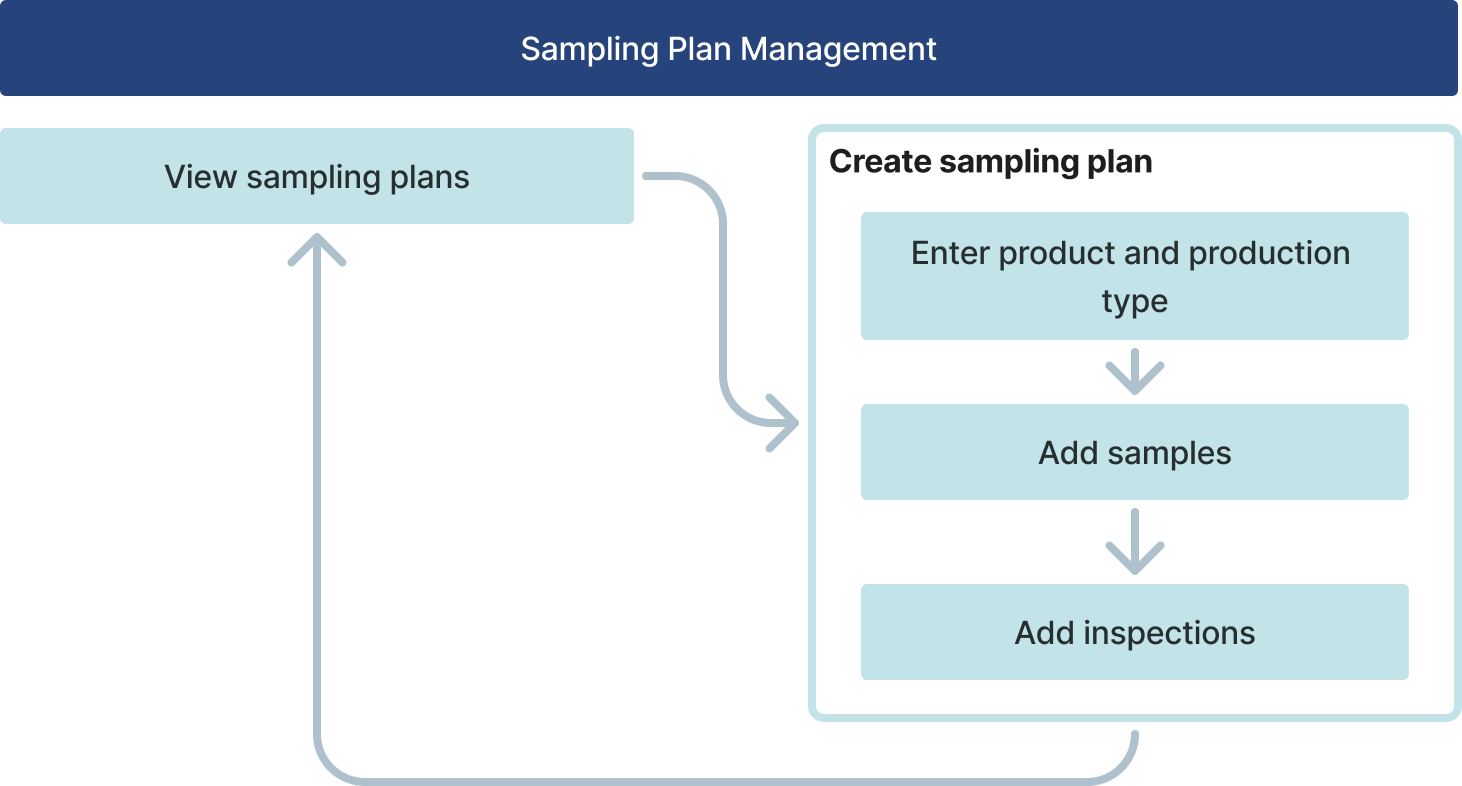

Gestión de planes de muestreo

Esta aplicación permite al usuario revisar los planes de muestreo y añadir nuevos planes de muestreo para cualquier producto y tipo de producción.

Cuadro de mandos del laboratorio

El panel de control del laboratorio ofrece una vista centralizada de las principales métricas y actividades del laboratorio, incluidas las tareas pendientes, los comentarios abiertos y las excepciones, lo que garantiza que los usuarios estén informados sobre las acciones críticas. También muestra los resultados actuales de las inspecciones, el número de muestras pendientes y un gráfico que resume las tendencias de las inspecciones, lo que permite un seguimiento y una toma de decisiones eficaces.