Introduction

These automations show AI agentic capabilities of Tulip, showcasing a defect management use case.

We built two Tulip automations:

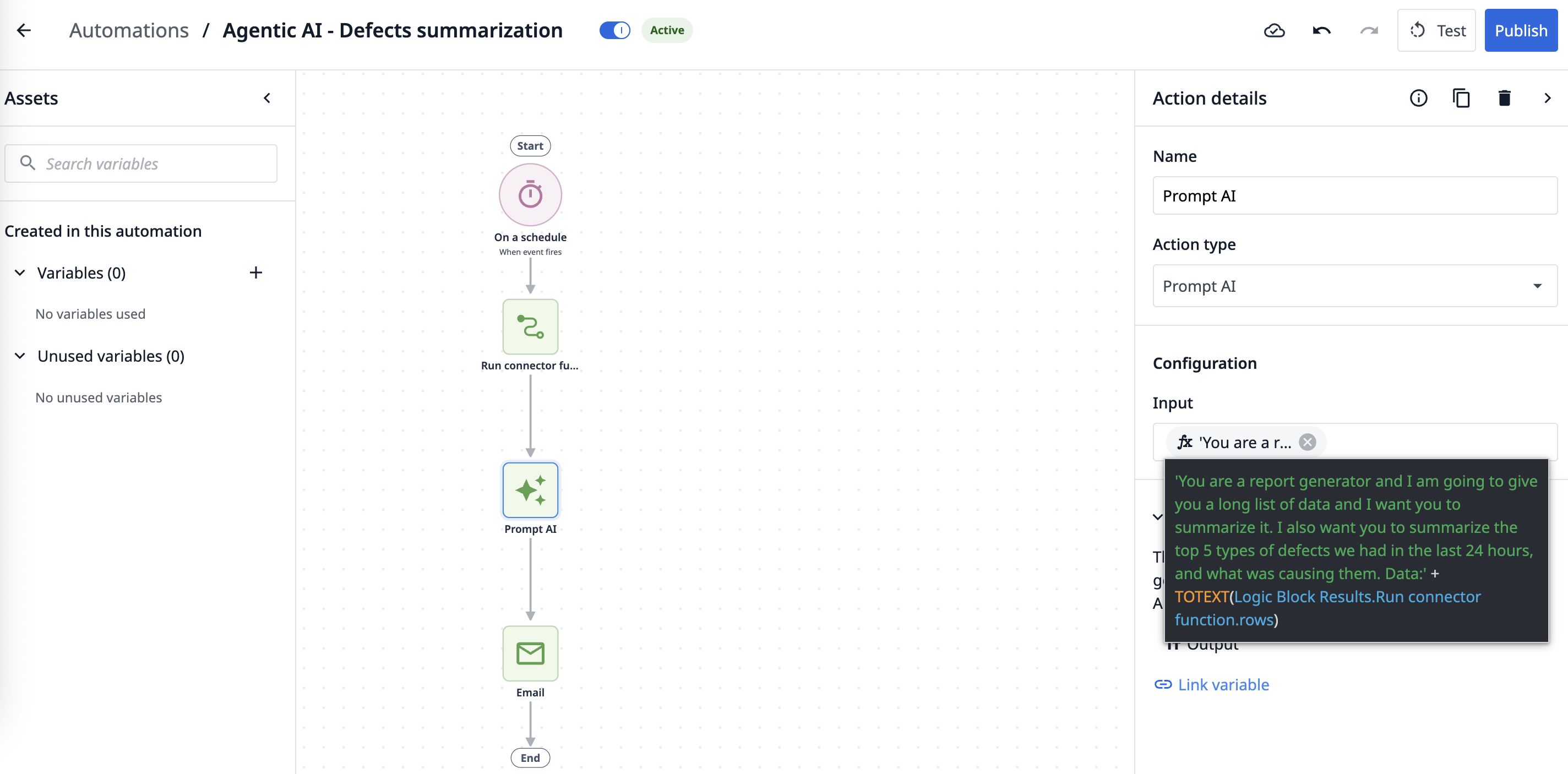

- one for summarizing defect records from the defects table and creating a daily email,

- another that gets triggered when a new defect record is created and will try to categorize it like a human engineer would in the Material Review Board application. It can change the disposition of the defect according to the category and send an email. If the automation cannot clearly determine the category then it sends a message to a supervisor to take a look in the MRB app.

With the MRB app we can create different types of defects and save them to the table to see how the automations handle them.

Setup

Both automations use the new Prompt AI action. See release notes here.

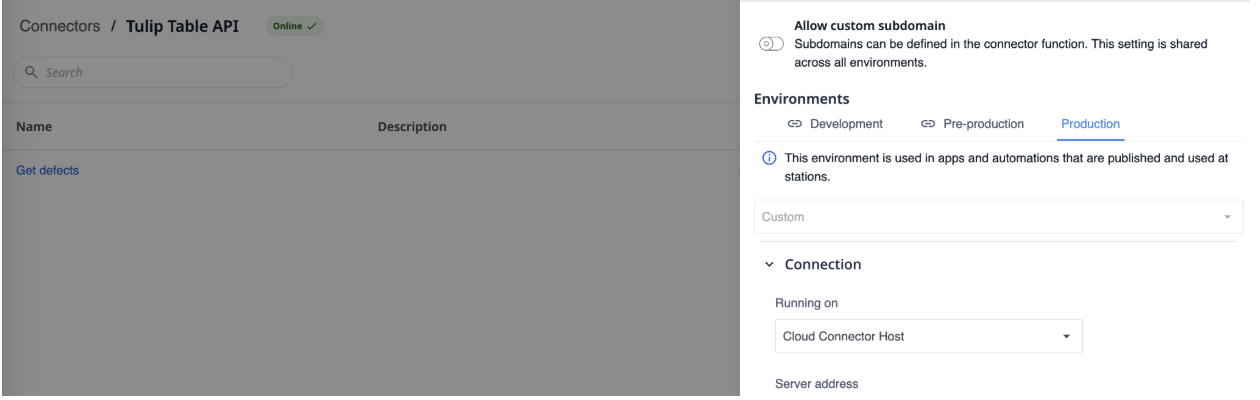

The Summarization automation uses the Tulip Table API as well to read data from the defects table. Here you need to generate a Tulip apikey first (read more about this here), then add it to the Tulip Table connector.

The automations send email notifications to specified users so you need to add a Tulip user with a verified email address at all the email actions.

Defects Summarization

This automation is triggered each morning, gets the defect records from the table via the Tulip Table API and then sends the data to the LLM to generate a report about defects in the last 24 hours.

An example email message

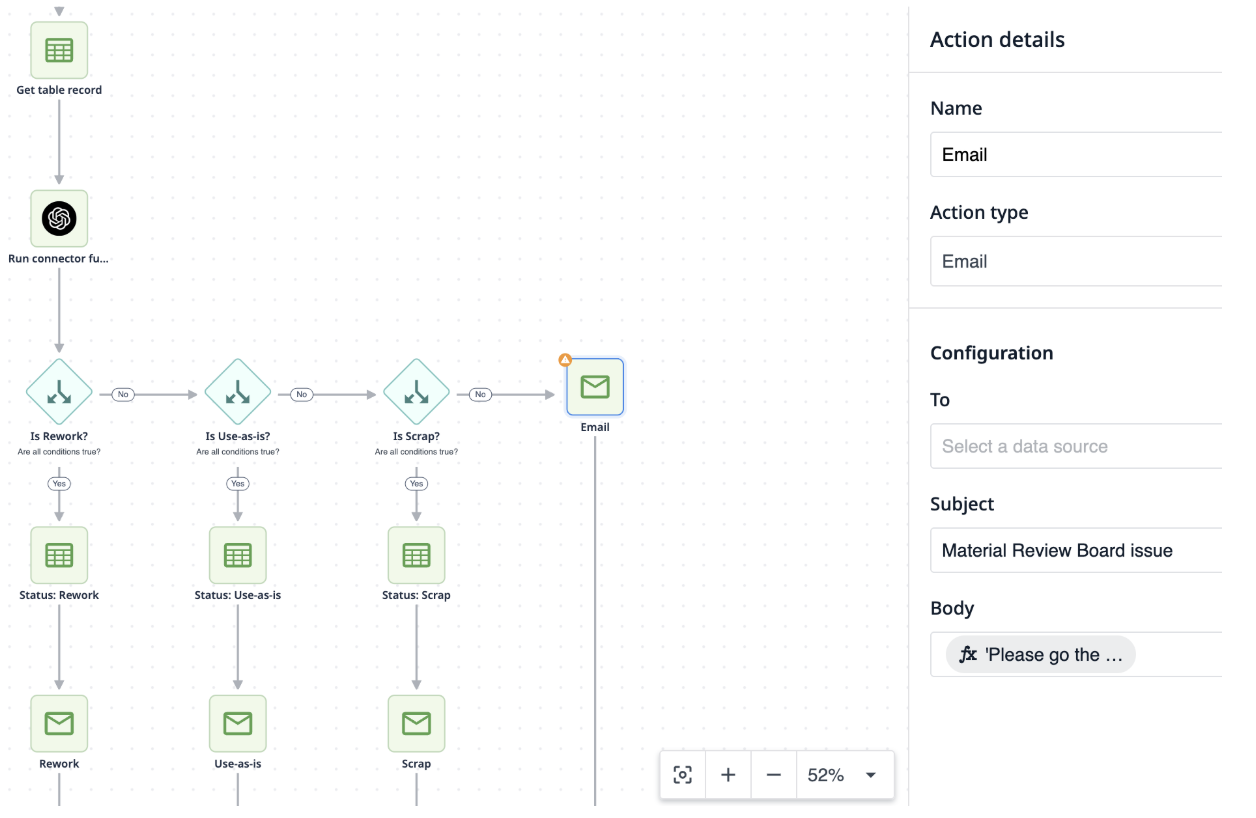

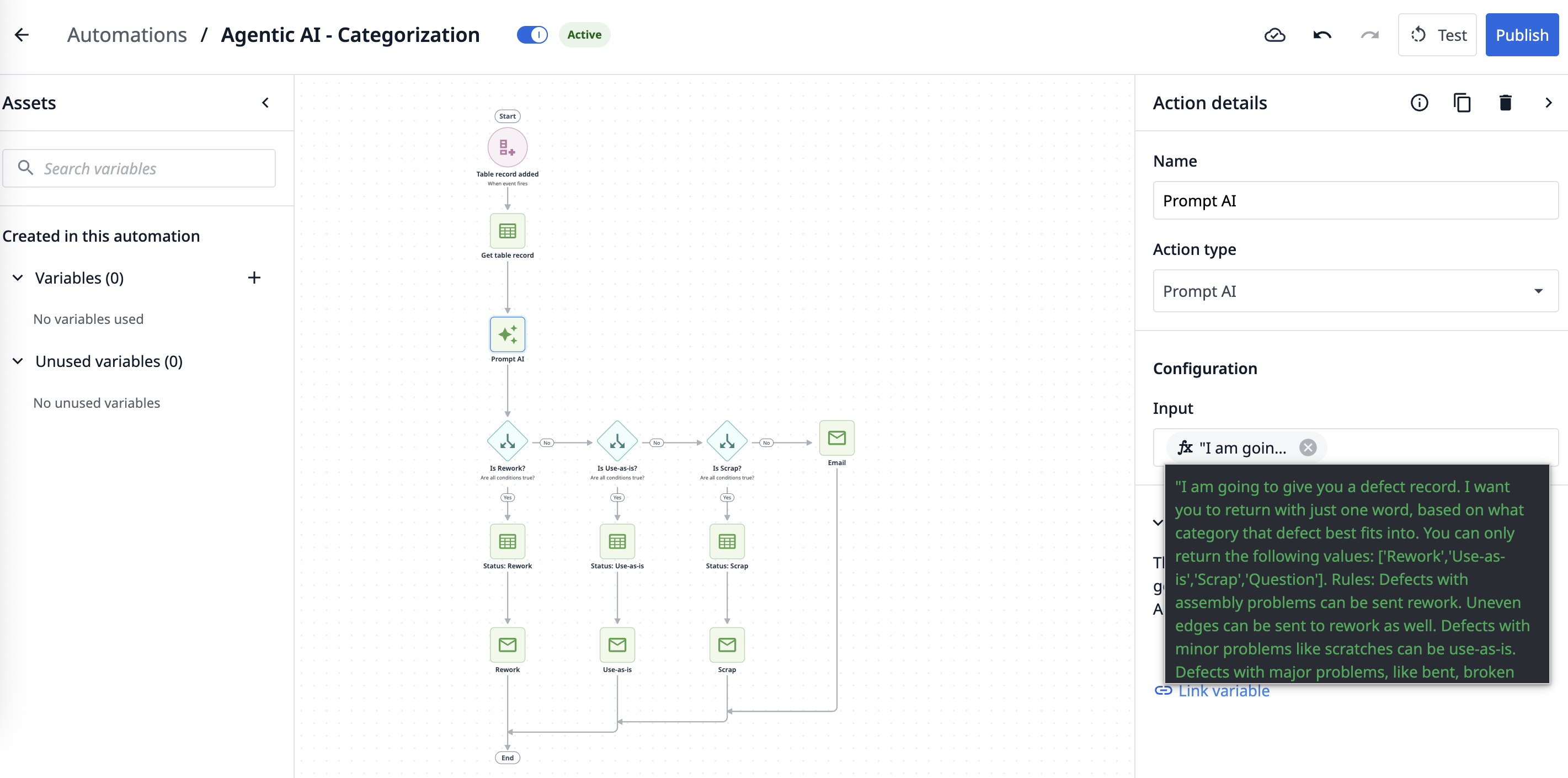

Categorization (scrap, use-as-is, rework, question)

When a new defect is added to the Defects table, the automation will categorize it as Rework, Scrap, Use-as-is or Question (for a human operator). It will change the status accordingly and send an email.

The prompt for categorization is:

“I am going to give you a defect record. I want you to return with just one word, based on what category that defect best fits into. You can only return the following values: [‘Rework’,‘Use-as-is’,‘Scrap’,‘Question’]. Rules: Defects with assembly problems can be sent rework. Uneven edges can be sent to rework as well. Defects with minor problems like scratches can be use-as-is. Defects with major problems, like bent, broken parts are scrap. If you cannot clearly decide, you can use ‘Question’, and it will be sent to a human quality engineer for making the decision. Here is the defect record data:”

An example email message