The app suite with the automation is available in the Tulip Library.

About TMS DX Consulting

TMS DX Consulting is a certified Tulip Solutions Partner specializing in Life Sciences.

Purpose

Time Out of Refrigeration (TOR) is the cumulative duration a temperature-sensitive material spends outside its designated storage conditions (such as refrigerated, frozen, or controlled ambient environments). It is also called Cold Chain Tracking of Temperature-Sensitive Material.

Why TOR Matters?

-

Product Integrity

- Materials like vaccines, biologics, and food products can degrade if exposed to incorrect temperatures for too long.

- TOR tracking ensures these materials remain safe and effective until use.

-

Regulatory Compliance

- Regulations such as FDA, EMA, and WHO require proof that materials in the cold chain are stored and handled according to their designated requirements.

- TOR records provide the evidence needed for audits and inspections.

-

Operational Efficiency

- Without TOR tracking, organizations risk discarding material unnecessarily or, worse, using compromised material.

- Real-time TOR tracking reduces waste while preventing unsafe use.

-

Business Impact

- Each unit of sensitive material often carries high value.

- Accurate TOR monitoring reduces financial losses and protects customer trust.

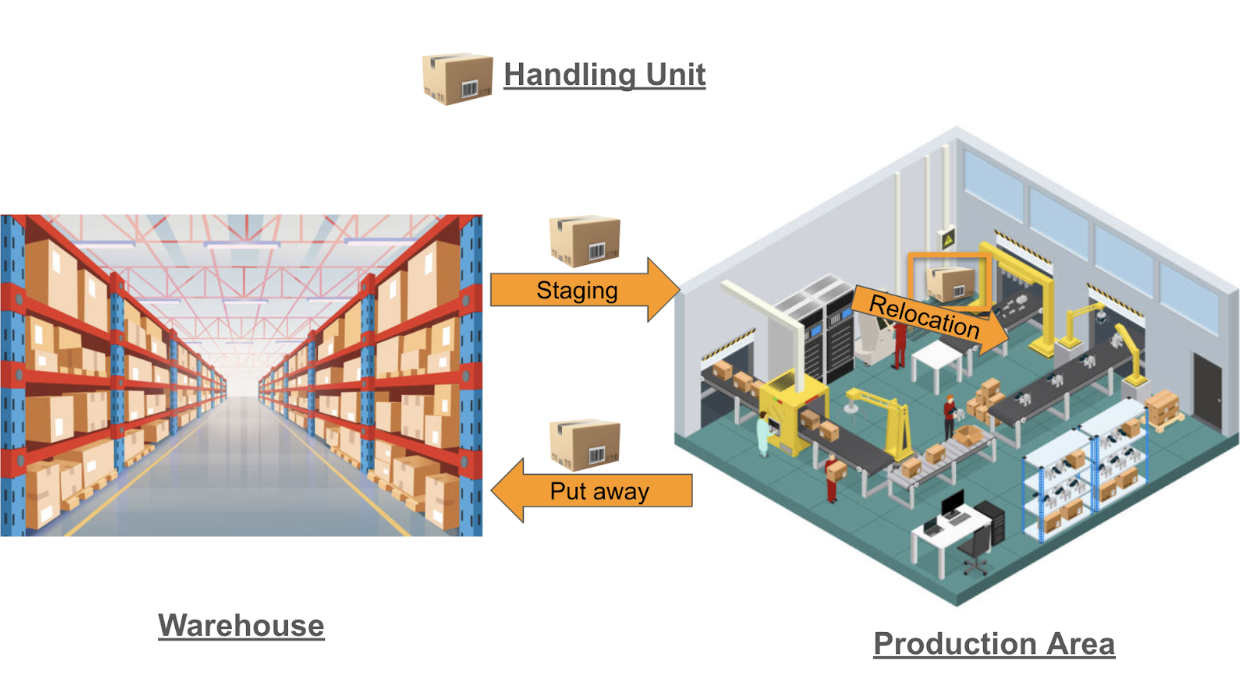

TOR in Inventory Operation

TOR must be tracked during all key inventory operations where Handling Units (HUs) may leave their designated storage conditions. These moments represent the highest risk for cold chain breaches.

Staging

Material issued from the warehouse and moved to a production staging area (near the line).

This activity creates a digital twin of the Handling Unit (HU) in Tulip, initiating TOR tracking.

Relocation

Material moved from one location within the production area to another (e.g., between lines, workstations, or from refrigerated to ambient storage and vice versa).

This activity updates the HU’s location in Tulip and adjusts relevant TOR characteristics to reflect the new conditions.

Putaway

Material moved from the production area back to the warehouse (unused, returned stock, or finished goods).

This activity logically deletes the HU record in Tulip, handing back full inventory ownership to the warehouse.

TOR Solution Architecture

The TOR Inventory solution is a comprehensive functionality designed to track and manage temperature-sensitive materials during different inventory operations. It is composed of a app suite and automation that work together to provide real-time visibility and control.

TOR Inventory Operation App Suite

TOR Inventory Operation App Suite consists of two apps:

- TOR Inventory Operation Terminal App: This app is the core of the inventory operations. It's built around three key inventory activities: Staging, Relocation, and Put Away. Each activity serves to update a digital twin of the Handling Unit (HU) within the Tulip scope of the production facility. Critical TOR tracking parameters, such as location type (COOL vs. AMBIENT), TOR warning limit, and TOR maximum limit, are continuously updated as HUs move through these processes.

- TOR Dashboard App: This application provides a high-level overview of TOR-related KPIs. It summarizes data at the HU, Batch, and Storage Location levels, giving supervisors and managers important insights into which HUs require immediate attention to prevent spoilage or quality issues.

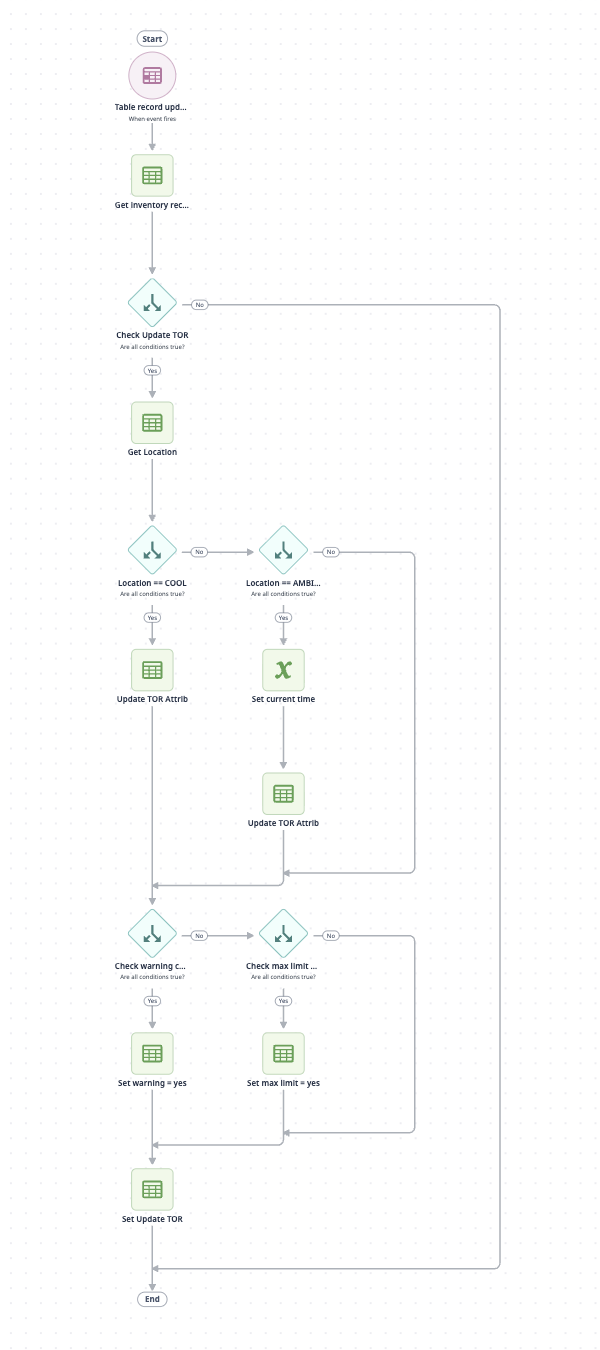

TOR Update Automation

TOR is a dynamic material characteristic influenced by events on the shop floor, such as relocation. Tulip's Automation feature allows for the creation of a composable logic to update the TOR of each HU based on different event. This automation can be triggered by events within an app, such as the relocation event built into the prototype, or by third-party systems, ensuring that TOR values are always current and accurate.

How is TOR calculated?

TOR is calculated by measuring the total duration a HU spends outside of the COOL storage location. This is typically done using timestamps that capture the moment an HU exits a cold storage environment and when it re-enters it. The system accumulates this time to determine the total TOR.

For example, when a product moves from a COOL (refrigerated) location to an AMBIENT (room temperature) location, we track the exit time. When it is put back into a cool location, we track the entry time, and that duration is added to the HU’s total TOR. This allows the system to continuously monitor the remaining "safe" time for each item.

In this design, the TOR warning limit and TOR maximum limit are key material characteristics that define the acceptable time a product can be out of a refrigerated environment. The app uses these values to actively manage and track the condition of each Handling Unit (HU).

TOR Warning Limit: This limit serves as an early alert system. When the cumulative TOR for a specific HU exceeds its material's predefined warning limit, the app can trigger a notification during inventory operation. The purpose is to give users a chance to take corrective action, such as immediately returning the HU to a cool location, before the material is compromised.

TOR Maximum Limit: This is the hard, non-negotiable threshold. When the cumulative TOR for a HU reaches or surpasses its material's maximum limit, the app's logic treats the material as compromised. Such HUs cannot be used in production as it would compromise product quality.

Data Model

The solution uses some modified tables from Tulip’s common data model to represent various artifacts:

- Inventory Units (Physical artifact): Represents the physical Handling Units (HUs) being tracked. Each HU is a digital twin with its own set of attributes. This includes the current TOR value and other TOR-related attributes like the timestamps for the last time the HU entered a COOL location, the last time it entered an AMBIENT location, and the last time its TOR value was updated. These attributes are essential for calculating TOR at any given moment.

- Storage Location (Physical artifact): Defines the physical locations where HUs are stored. Each location is characterized as either COOL or AMBIENT and is crucial for calculating TOR exposure.

- Material Master Definition (Reference): A reference table containing static information about each material, TOR warning limit, TOR Max limit

App Design Walkthrough

The TOR Inventory Operation Terminal App is designed for a simple, guided user experience. The primary interaction involves barcode scanning and on-screen prompts to move through each workflow.

- App Navigation: Users begin by selecting one of the three core inventory operations: Staging, Relocation, or Put Away.

- Staging Workflow: This is a multi-step process for introducing a new HU. The user scans the HU ID, Material ID, and Batch ID in sequence. Confirming this final step triggers the app to create a new record and initialize the HU's digital twin in the system.

- Relocation Workflow: This process moves an existing HU. The user scans the HU ID and then the Target Location barcode. Confirming the move updates the HU's location and associated TOR timestamps.

- Put Away Workflow: The user scans the HU ID and confirms the action, which updates the HU's put away status.

How to adapt this for your Inventory operation?

This app is a flexible template that can be easily adapted to fit the unique requirements of your inventory operations. Its modular design allows for customization in several key areas.

- Data Model: You can easily add new fields to the existing tables to capture more specific data.

- Workflow Logic: The app’s step-by-step processes can be modified to match your exact procedures. You can add new steps (e.g., a mandatory quality check before staging), reorder existing steps (e.g., scan batch ID before material ID), or modify scanning logic to accept all information concatenated into a single GS1 barcode.

- Automation & Integration: The app can be connected to your existing enterprise systems. You can create automations to automatically listen to an event from your WMS or ERP system, ensuring real-time synchronization. This can automate tasks like creating new HUs from a transfer order confirmation or updating HU’s storage location based on IIOT sensor integration. You could also build notification feature in the automation to send notification to production supervisor or other relevant user group when a HU TOR reached warning and/or maximum TOR limit.

How to configure and deploy this app?

Step 1: Download App and Automation

Download the TOR Inventory Operations Terminal App and its associated automation logic directly from the Tulip Library.

Step 2: Define Master Data

Before using the app, populate the required master data tables:

Material Master Definition: Define your materials, including their TOR Warning Limit and TOR Maximum Limit.

Storage Locations: Define your locations and specify if they are COOL or AMBIENT.

Step 3: Adapt the App to Your Workflow

Customize the app's logic to fit your specific operations:

Workflow Logic: Add, remove, or reorder steps (e.g., enable single GS1 barcode scanning).

Data Model: Add custom fields to the Current HU table as needed.

Step 4: Test and Validate

Thoroughly test the app to ensure all functions, especially TOR calculations and alerts, work correctly. Use a risk-based validation approach to focus on the most critical features.

Step 5: Deploy and Capture Feedback

Deploy the app to your users. Collect their feedback to identify areas for continuous improvement and further refinement.