Download the app suite.

アプリ・グループで使用されるチューリップ・テーブル

アプリ・グループのアプリケーションは、2つの重要なテーブルを利用しています:設備と資産」と「コメントと例外」です。

コメントと例外」テーブルは、プロセス中に発生した予期せぬイベントや、オペレーターが作成したコメントを記録するために使用されます。これらのテーブルは、効率的なデータ整理とスムーズな運用管理を保証し、関連するすべての情報を一箇所に保管します。

設備ステータスの管理

このテーブルでは、2つの異なるタイプのステータスを追跡します:

校正ステータス - これは機器の校正状態を反映します。清浄度と使用状況ステータス - これは機器の清浄度と使用状況を示します。両方のステータスフィールドについて、テーブル内に時間フィールドと日付フィールドを追加し、最新のステータス変更のタイムスタンプを保存します。

これらのフィールドは、事前定義されたプロセスや条件に基づいて、ユーザーの介入なしにバックグラウンドで機器のステータスを自動的に更新するオートメーションを作成するために使用できます。

これらのオートメーションがどのように機能するかについては、次を参照して ください:Calibration Status Reset Equipment Status Reset。

Equipment Logbook App Groupのアプリケーション

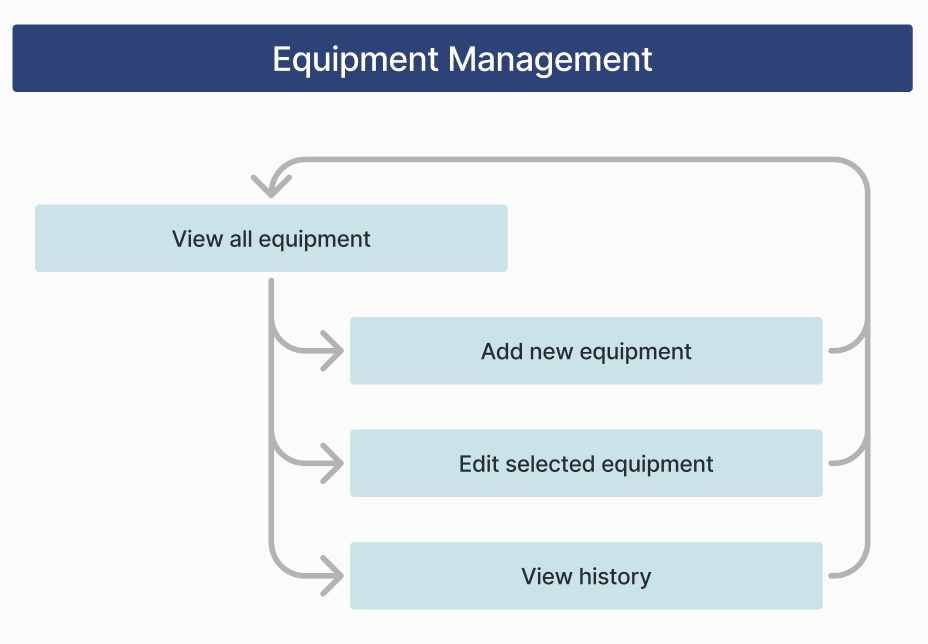

設備管理

{高さ="" 幅="600"}。

{高さ="" 幅="600"}。

このアプリケーションでは、ユーザーは必要な情報を提供した後、[**機器と資産]**テーブルで資産を作成したり、選択した資産の詳細を変更したりできます。**履歴の表示」**ステップでは、選択した資産の監査証跡を確認することができます。監査証跡は、日付を指定することで、特定の時間間隔にフィルタリングすることができます。

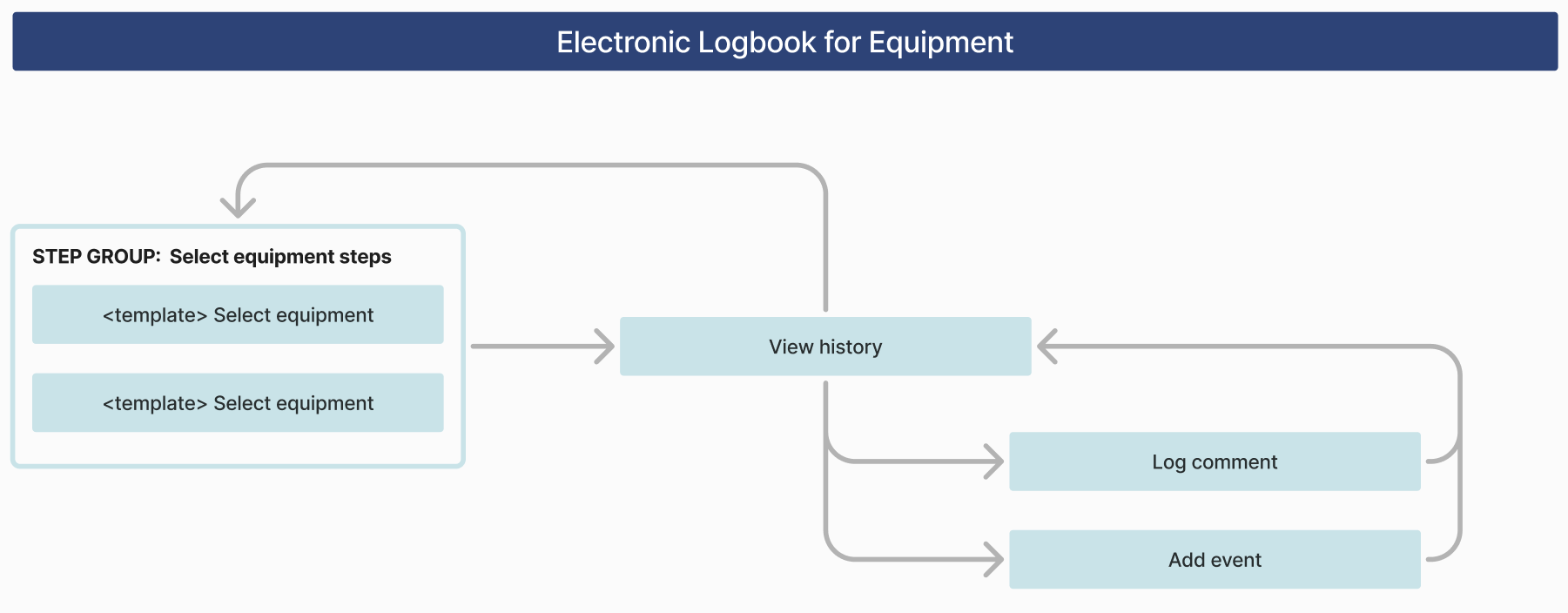

設備電子日誌

{高さ="" 幅="" }。

{高さ="" 幅="" }。

このアプリケーションは、紙ベースの日誌の電子版です。資産を選択した後、ユーザーは履歴を見るステップに進み、そこで資産の履歴データを見ることができます。

:::(Warning)The app offers two options for selecting the asset. In the first option, the equipment can be selected from a table, and in the second option, the asset can be identified using an optical barcode scanner. It’s not mandatory to use both options. Choose the one that best supports your process.

:::

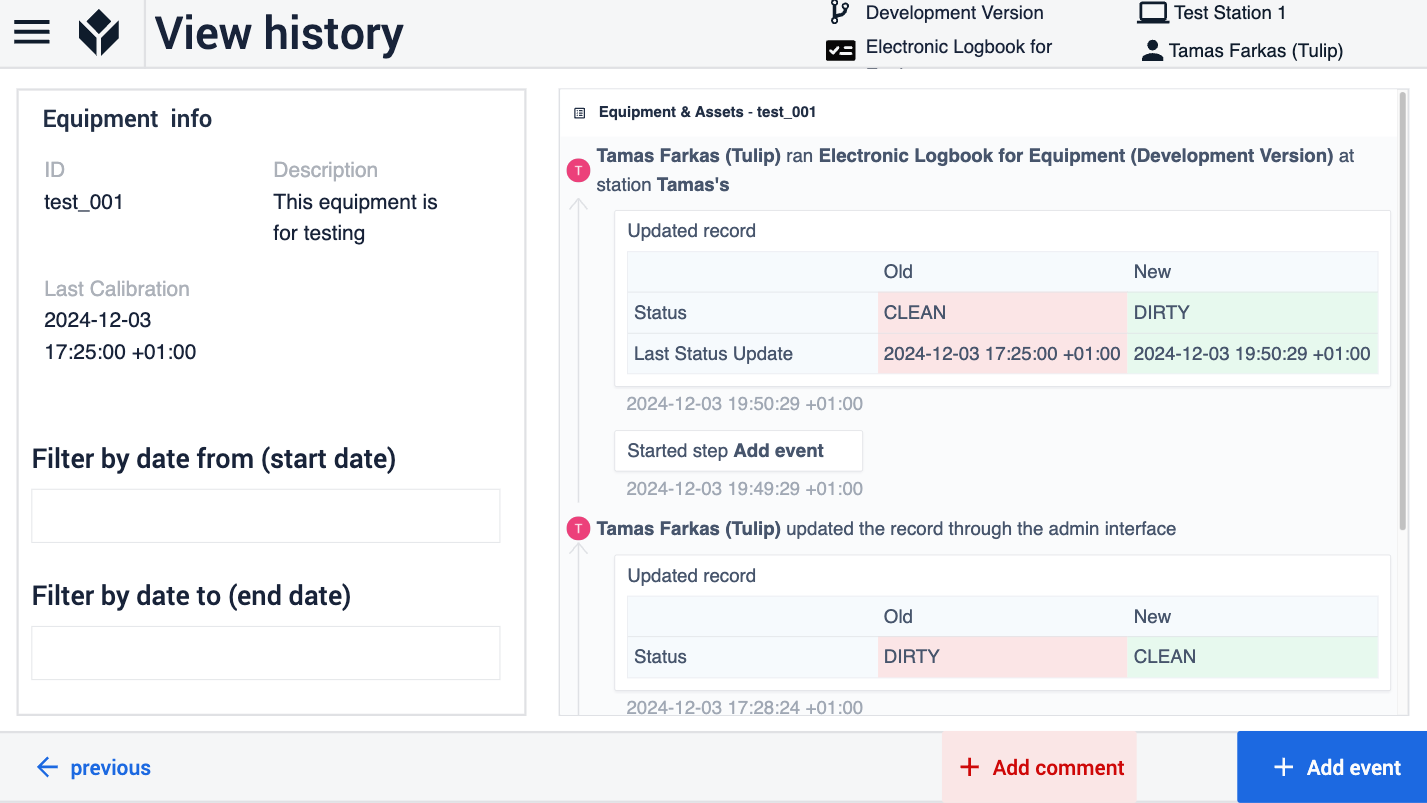

{高さ="" 幅="600"}。

{高さ="" 幅="600"}。

履歴の表示ステップでは、2つのオプションがあります。イベントを追加する場合、アプリケーションはオペレーターをイベントの追加ステップにナビゲートします。選択した操作により、資産の新しいステータスが自動的に表示されます。

| 操作 | ステータス |

|---|---|

| クリーニング | クリーニング |

| 本番使用(開始) | 使用中 |

| 生産使用(終了) | DIRTY |

Saveボタンを押すと、変更が確定され、履歴の表示ステップに戻ります。もう1つのオプションは、[Comments and Exceptions]テーブルに新しいコメントを記録することです。