Tulip offers flexibility in how you structure apps around machines. The right pattern depends on your team's technical maturity, process standardization, and budget.

Pattern 1: Composable machine apps (1:1 model)

Structure: One machine → One app → One station → One terminal

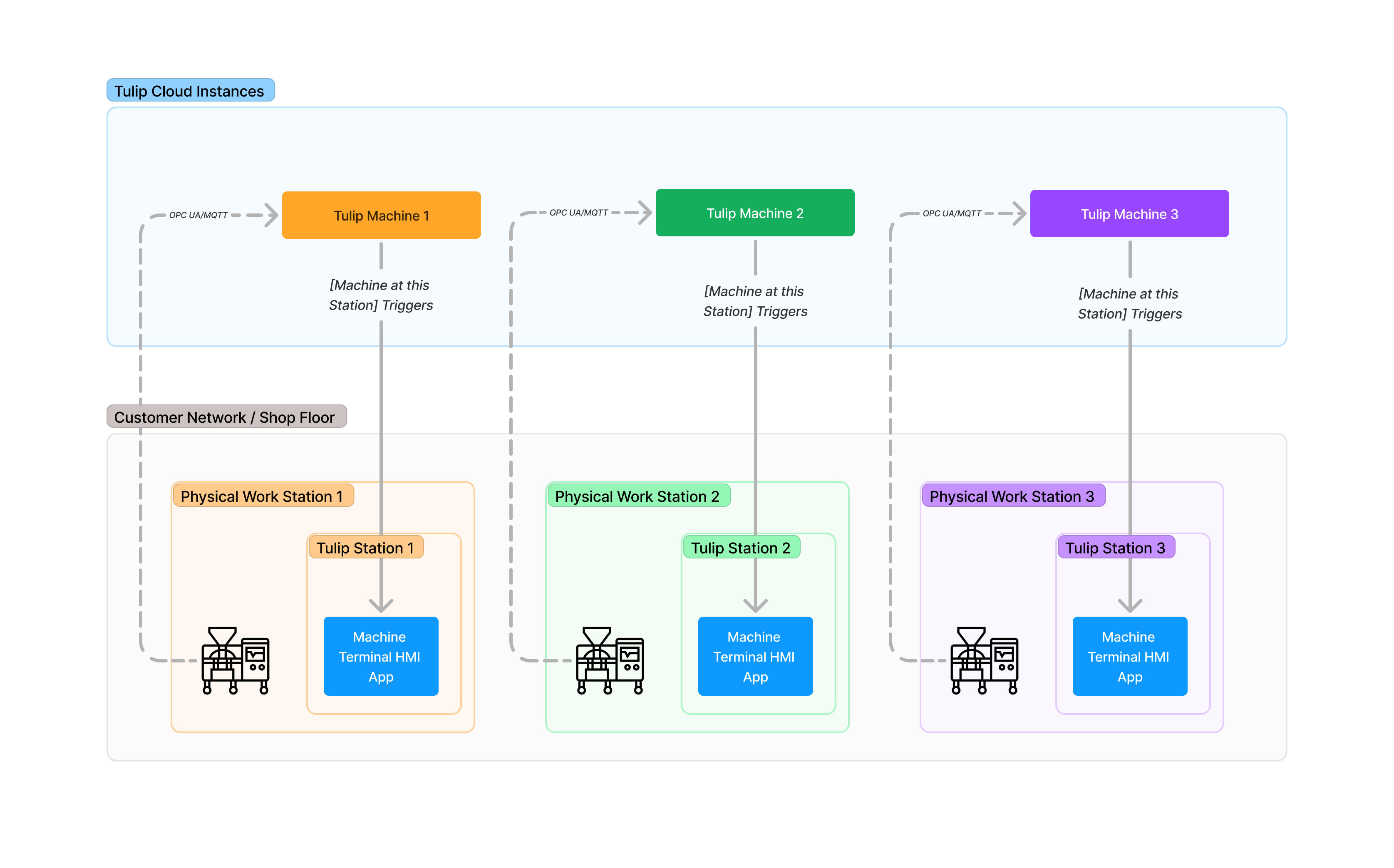

Architecture diagram:

.png)

Use cases

- Entry-level citizen developers building their first machine monitoring apps

- Quick proof-of-concept deployments where simplicity outweighs efficiency

- Custom human processes per machine instance (e.g., Machine 1 requires unique inspection steps not applicable to Machine 2)

- Operations-led development where developers have multiple roles and limited time

Why this matters

This pattern physically maps software to hardware 1:1, eliminating abstraction. Developers can identify a machine on the shop floor and map it to its own app. This clarity reduces mental effort and makes troubleshooting intuitive.

Example

Scenario: A food and beverage manufacturer has 3 packaging lines. Each line has unique downtime reasons, part configurations, and operator workflows.

Implementation

- Create Machine Type: "Packaging Line"

- Create 3 machines: "Line A", "Line B", "Line C"

- Build 3 apps: "Line A Terminal", "Line B Terminal", "Line C Terminal"

- Assign each app to a dedicated station with a fixed terminal

Benefits

- Clear data isolation prevents cross-machine data corruption

- Easy to customize per-machine workflows

- Simple troubleshooting (problem is always in one self-contained app)

Limitations

- Requires one physical terminal per machine (hardware cost)

- Global app changes require updating 3 separate apps

- Not scalable beyond approximately 10 machines

Pattern 2: Machine assignment to station app

Structure: One machine type → One app → Multiple stations (machine dynamically assigned via station mapping)

Architecture diagram:

Use cases

- Standardized processes across identical machine types

- Full-time citizen developers comfortable with abstraction and trigger logic

- Horizontal scaling needed (10+ machines of same type)

- Centralized app maintenance is a priority

How it works

- Assign each machine to a station in Shop Floor > Machines (Configuration tab)

- In the app, use "at this station" trigger conditions to dynamically reference the assigned machine

- When the app runs on Station 1, it interacts with Machine 1. When it runs on Station 2, it interacts with Machine 2

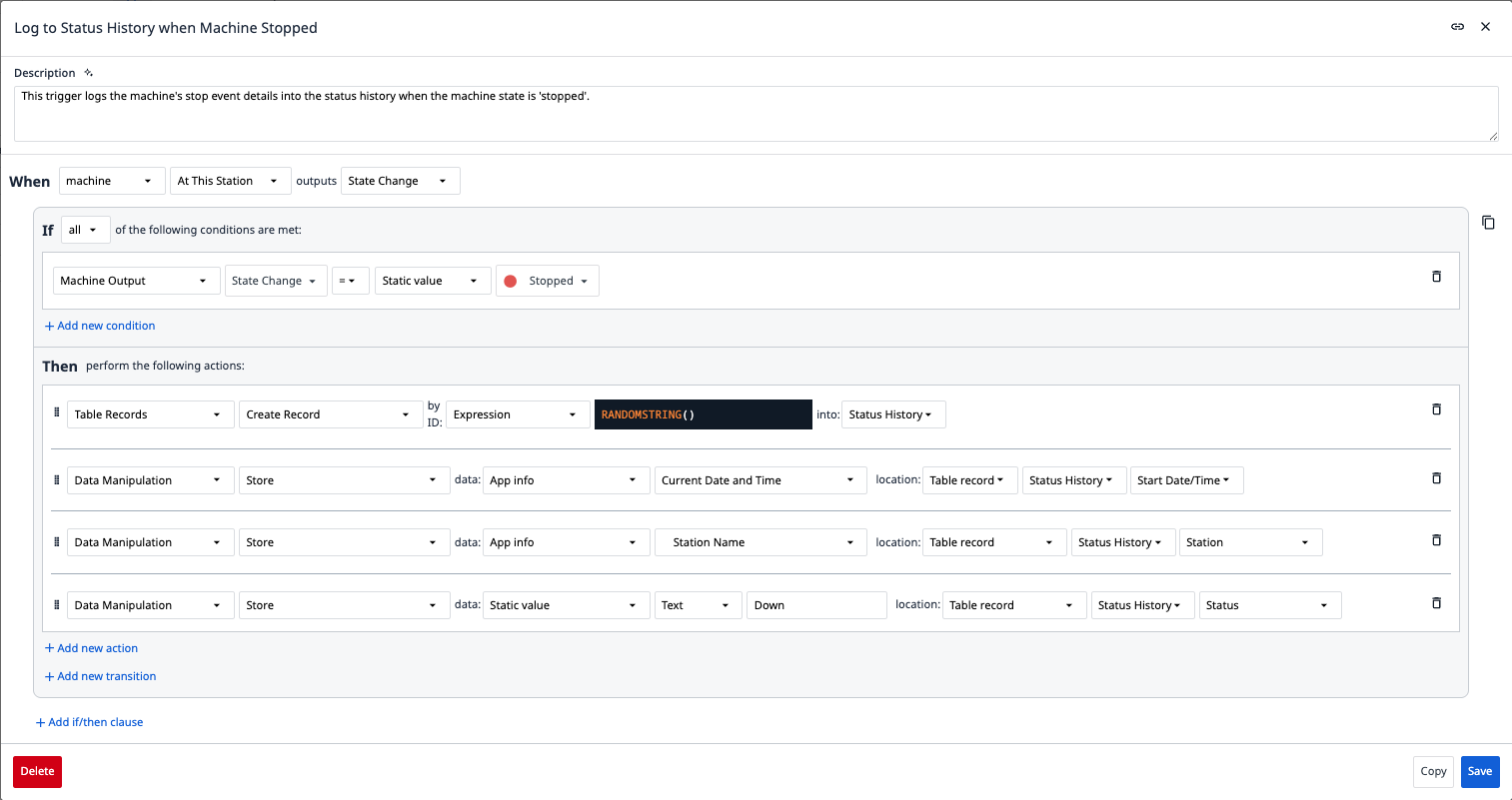

Example app trigger

When: Machine at this station outputs State Change

If: Machine Output / State Change = Down

Then: Create Table Record in 'Status History' Table.

Example

Scenario: Automotive tier-1 supplier has 15 identical CNC mills running the same production process.

Implementation

- Create machine type: "CNC Mill 5-Axis"

- Create 15 machines (CNC-001 through CNC-015)

- Build one app: "CNC Operator Terminal"

- Create 15 stations, assign one machine to each

- Deploy the single app to all 15 stations

Benefits

- Single app to maintain (global updates propagate instantly)

- Reduced app development time for fleet deployments

- Uses "at this station" trigger logic (built-in dynamic machine reference)

Limitations

- Still requires one terminal per station (hardware cost remains)

- All machines must be the same type with identical attributes

- Custom per-machine logic requires conditional branching (added complexity)

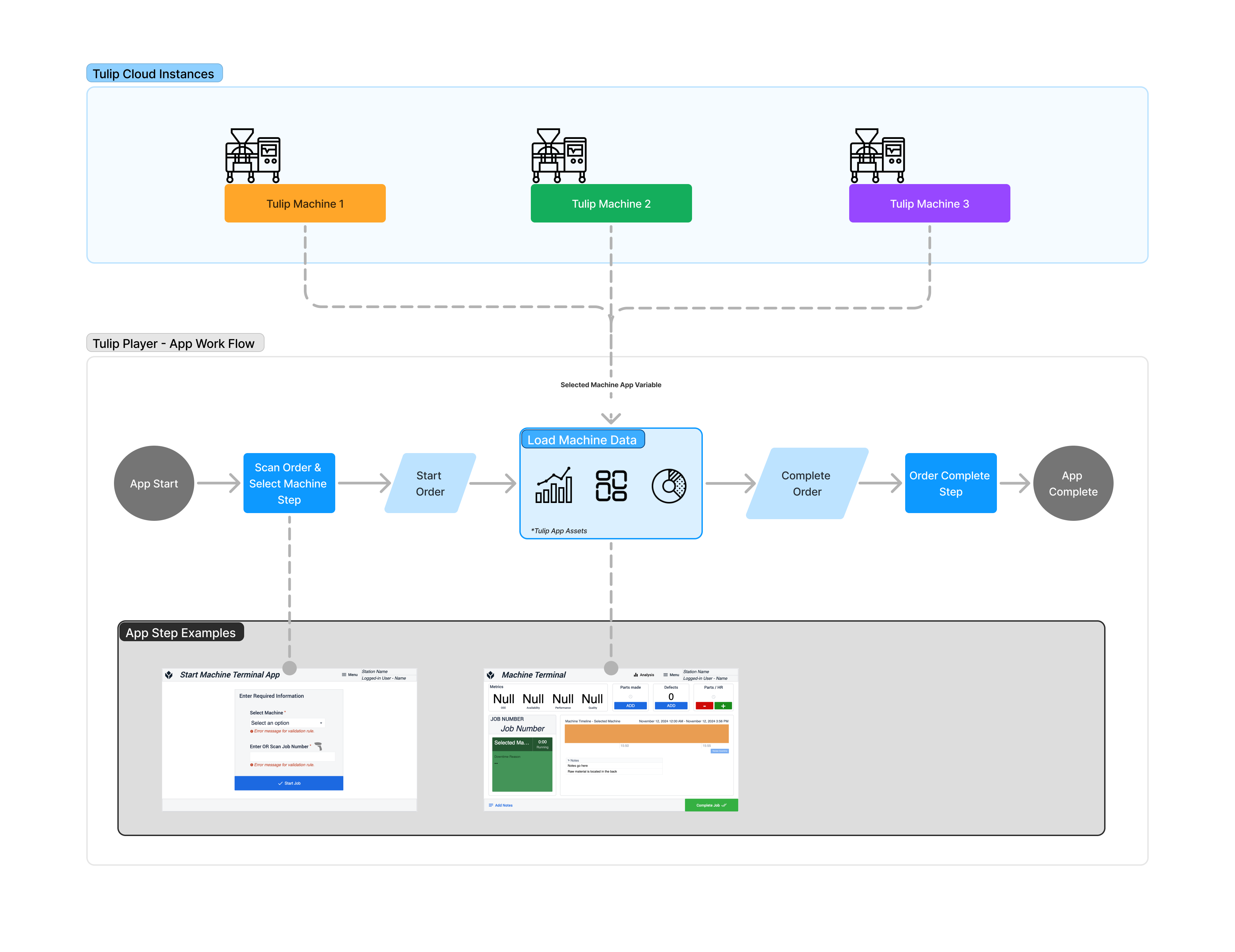

Pattern 3: Machine variable app (floating terminal)

Structure: One app → Multiple machine types → Variable-based machine selection → Shared/floating terminal

Architecture diagram:

Use cases

- Budget constraints: Limited terminals available

- Floating operator model: One operator moves between machines with a shared iPad

- Machines don't require continuous monitoring: App only needs to run during active operations

Critical limitation: Not headless

This pattern does not support background/headless monitoring. If the app is closed, then no machine triggers fire. This pattern is only suitable for:

- Human-initiated data entry (operator logs defects, part counts)

- Ad-hoc machine inspections

- Scenarios where machines don't generate data when app is not running

How it works

- Create a machine variable in the app (e.g.,

selectedMachine) - Add a dropdown widget or QR code scan to populate

selectedMachineat runtime - Use

selectedMachinein all trigger references

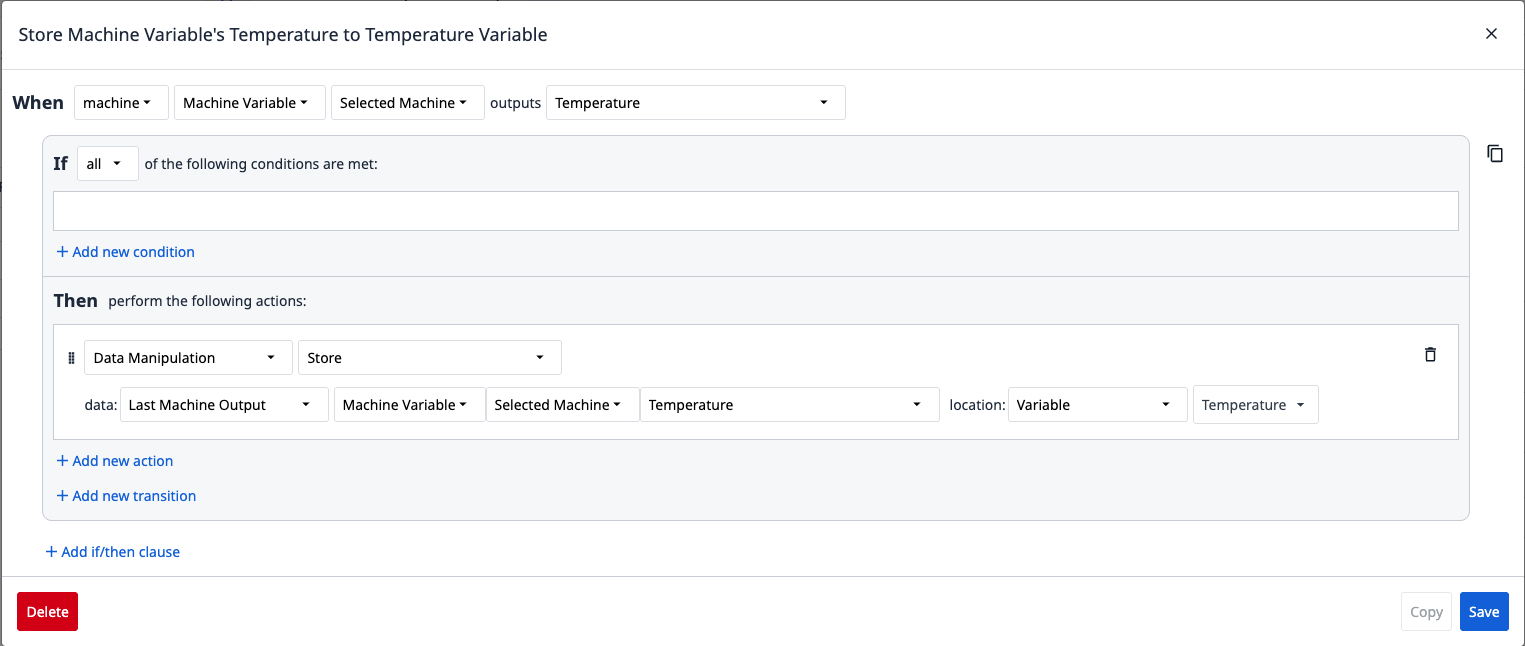

Example app trigger

When: machine Machine Variable 'Selected Machine' outputs {Attribute}

Then: Store Last Machine Output to Variable

Example

Scenario: Pharmaceutical lab has 5 analytical instruments that only run during scheduled tests. Technicians use a shared iPad to log test parameters and results.

Implementation

- Create 5 machines (HPLC-1, GC-MS-2, etc.)

- Build one app: "Lab Equipment Log"

- Add dropdown: "Select Instrument" → populates

selectedMachinevariable - Technician carries iPad between instruments, selects active machine, logs data

Benefits

- Minimal hardware cost (one shared terminal)

- Flexible machine selection at runtime

- Ideal for ad-hoc/intermittent workflows

Limitations

- Not headless - app must be actively running for any logic to execute

- No background monitoring when app is closed

- Complex state management (Which machine is currently active?)

- Not suitable for 24/7 OEE tracking

Architecture pattern decision tree

Use this decision tree to select the best pattern for your needs:

Further reading

Did you find what you were looking for?

You can also head to community.tulip.co to post your question or see if others have solved a similar topic!