Overview

This article introduces the Model Context Protocol (MCP), explaining its role as a vital intermediary enabling Large Language Models (LLMs) to intelligently interact with manufacturing systems like Tulip. You will learn how the MCP provides LLMs with the necessary context to understand and manage your factory floor.

Key topics covered include:

- Understanding MCPs: What they are and why they are essential for LLM integration in manufacturing.

- Tulip MCP Capabilities: A detailed look at how the Tulip MCP allows LLMs to manage manufacturing data, control shop floor operations, and handle user administration.

- Setting up Tulip MCP: Practical guidance on implementing the Tulip MCP in your environment.

What is an MCP

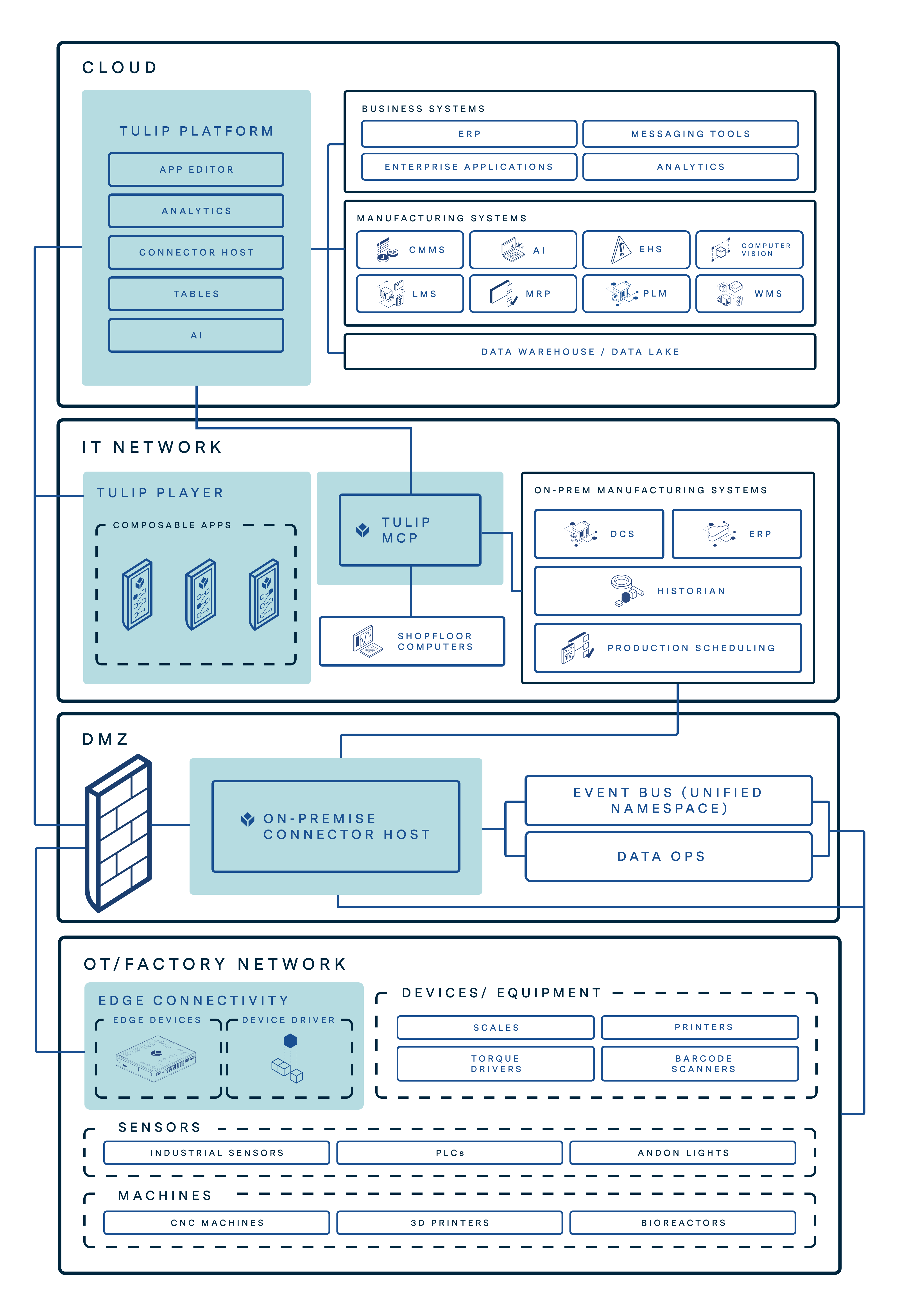

A Model Context Protocol (MCP) serves as a specialized data format, acting as an intermediary for Large Language Models (LLMs) to communicate with external systems in manufacturing. Think of an MCP as a middleware intended for use by an LLM. Unlike a standard API specification, an MCP is designed to provide LLMs with a richer, more contextual understanding of how to interact with the underlying industrial systems. This enhanced context is vital for the LLM to generate precise, actionable insights and commands tailored to the factory floor, thereby enabling more intelligent automation and decision-making.

Alongside acting as the specification for how the LLM should interface with the underlying system, MCP servers traditionally also proxy all traffic between the LLM and the underlying system. To that end, MCPs must be hosted in a location the LLM can access.

The primary benefit of employing an MCP is its ability to bridge the gap between high-level AI reasoning and the intricate, dynamic environment of the shopfloor. By offering a standardized way to package and exchange contextualized information, an MCP facilitates a closed-loop system integration. This allows LLMs to not only receive operational data for analysis but also to effectively issue commands or recommendations that manufacturing systems can directly interpret and act upon.

What can I do with the Tulip MCP

The Tulip MCP is backed by the Tulip API, which enables access to create, configure, and monitor the shop floor from external systems.

1. Managing Manufacturing Data (Tables)

- Access Data: Retrieve lists of all your Tulip Tables and get details about specific tables or individual records within them.

- Manipulate Data: Create new tables, add new records to existing tables, and update or increment specific fields in records.

- Analyze Data: Count the number of records in a table and run aggregate functions (like sum or average) on table fields, enabling the LLM to perform basic data analysis directly.

- Manage Relationships: Create, update, link, and unlink relationships between different table records, which is crucial for managing complex manufacturing data structures (e.g., linking a production order to its associated materials and quality checks).

- Handle Files: Sign URLs for cloud storage, which implies the ability to interact with and manage files associated with production processes or quality documentation.

2. Monitoring and Controlling Machines and the Shopfloor

The Tulip MCP allows the LLM to interact with machine and system-level data and operations:

- Machine Insights: List different machine types and generate/retrieve archives of machine activity, providing valuable historical data for performance analysis or troubleshooting.

- Real-time Reporting: Report new values for machine attributes, meaning the LLM can feed real-time data into the system, potentially for dashboards, alerts, or further analysis.

- Interface Management: List, create, get details, update, and even archive interfaces, which are critical for connecting Tulip to other systems or hardware on the shop floor.

- Station and Station Group Management: Similar to interfaces, the LLM can list, create, retrieve details, update, and archive stations (individual workstations or production points) and station groups. This allows for dynamic reconfiguration or monitoring of your physical layout.

- App Assignments: Manage how applications are assigned to stations and station groups, enabling the LLM to control which apps are available at specific points in the manufacturing process.

3. User Management

The MCP also includes capabilities for managing user information within Tulip:

- User Information: List and retrieve details about user roles, user groups, and individual users, as well as see which user groups a specific user belongs to.

- User Creation (Admin): Create new user accounts, although this is flagged as a "dangerous operation" requiring extreme caution due to its direct impact on user access and security.